ph responsive polymer mixed micelle and application thereof

A technology for mixing micelles and polymers, which can be used in drug combinations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. It can solve the problems of sudden release, failure to achieve performance, and disintegration of micelles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

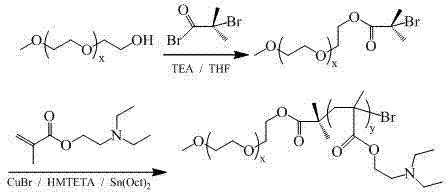

[0076] Synthesis of brominated polyethylene glycol (MPEG-Br): Weigh MPEG (5g, Mn=5000) and add the solvent into a dry 100ml anhydrous and oxygen-free reaction bottle, seal it with a reverse rubber stopper, and vacuumize - After blowing nitrogen gas for 3 times, under the protection of nitrogen gas, add the dehydrated solvent dichloromethane (30ml) and dehydrated triethylamine (TEA, 0.5ml) sequentially with a syringe, and then cool to 0°C in an ice bath, Slowly add 2,4-dibromoisobutyryl bromide (NA, 0.5ml) dropwise under stirring conditions, react at 0°C for 2h after the dropwise addition, then raise the temperature to 40°C, continue the reaction for 12h, after the reaction Wash with dilute hydrochloric acid and pure water three times respectively, drop the organic phase into 0°C n-hexane of ten times its volume to precipitate, filter, and finally vacuum-dry at 40°C for 48 hours.

Embodiment 2

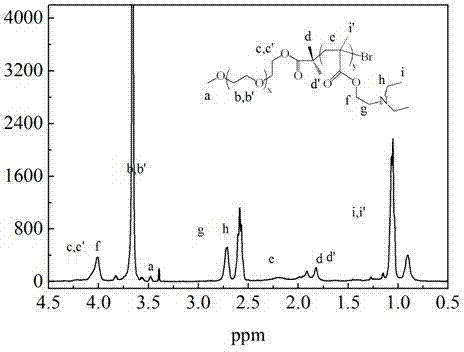

[0078] Synthetic MPEG-b-PDEAEMA 20 :

[0079] The pH responsive monomer DEAEMA (1.43g), MPEG-Br (2g), catalyst CuBr 2 (2.78mg) and solvent were added to a 150ml anhydrous and oxygen-free reaction bottle, sealed with a reverse rubber stopper, vacuumed-nitrogen three times, under the protection of nitrogen, added THF (35ml) to remove water with a syringe in turn, and prepared Body PMDETA (33.64mg) and reducing agent Sn(Oct) 2 (78.6 mg), after freezing in liquid nitrogen, vacuumize and blow nitrogen three times, stir for 15 minutes after thawing, then start to heat up, and react in an oil bath at 65°C for 24 hours. After most of THF was removed by rotary evaporation under reduced pressure, the organic phase was slowly added dropwise to 200ml of cold n-hexane to precipitate, filtered, and finally vacuum-dried at 45°C for 48h, Mn=9075.8, PDI=1.047.

Embodiment 3

[0081] Synthetic MPEG-b-PDEAEMA 35 :

[0082] The pH responsive monomer DEAEMA (2.5185g), MPEG-Br (2g), catalyst CuBr 2 (10.5mg) and solvent were added to a 150ml anhydrous and oxygen-free reaction bottle, sealed with a reverse rubber stopper, vacuumed-nitrogen three times, under the protection of nitrogen, add dehydrated toluene (30ml) with a syringe in turn, and prepare Body PMDETA (42.34mg) and reducing agent Sn(Oct) 2(89.6 mg), after freezing in liquid nitrogen, vacuumize and blow nitrogen three times, stir for 15 minutes after thawing, then start to heat up, and react in an oil bath at 80°C for 12 hours. After most of the toluene was removed by rotary evaporation under reduced pressure, the organic phase was slowly added dropwise to 200ml of cold n-hexane to precipitate, filtered, and finally vacuum-dried at 45°C for 48h, Mn=11098, PDI=1.054.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical micelle concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com