A production process of the standard part of the column cross support of the thickener

A production process and standard parts technology, which is applied in the field of thickener and thickener column cross support standard parts production process, can solve the problem of not finding the same or similar technical solutions, etc., so as to improve welding efficiency and welding accuracy, and improve production accuracy. , to ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

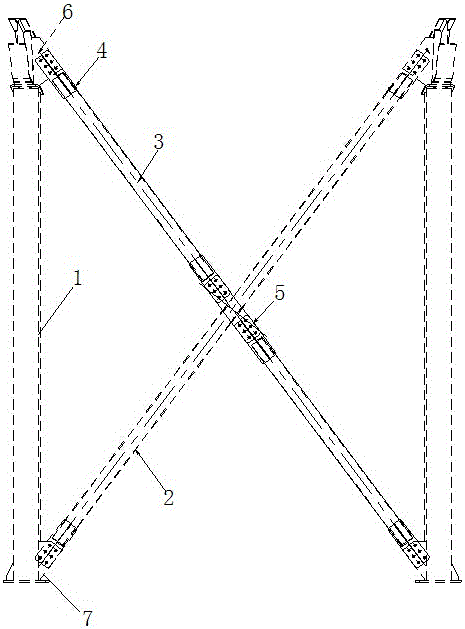

[0021] The invention discloses a manufacturing process for a standard cross support of a thickener column. The manufacturing process is that all bolt connection plates on the cross support are uniformly drilled with a drilling template, and then long and short pipes are made into a standard on the same universal frame Complete the welding of long and short pipe fittings and corresponding bolt connection plates.

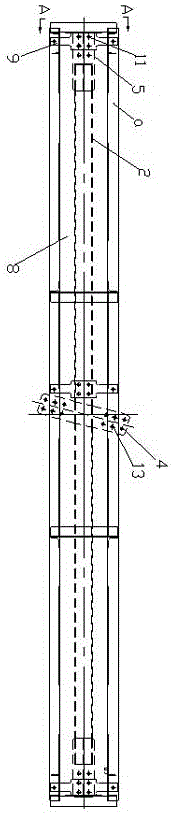

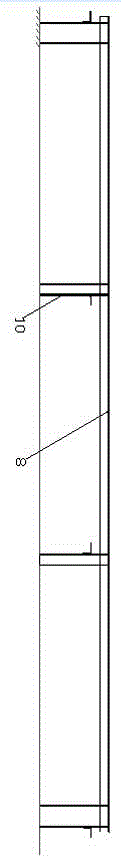

[0022] Such as Figure 2-Figure 4 As shown, the structure of the general tire frame involved in the above-mentioned manufacturing process includes a working platform 8 and several pipe support templates 9 evenly distributed along the long axis of the working platform 8 and used to support the long pipes 2 and the short pipes 3. The working platform 8 is arranged horizontally, the upper end surface is a rectangular frame, and the lower end surface is supported on the ground by a number of uprights 10 evenly distributed along the long axis direction. The working platform 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com