Copper plating solution capable of realizing co-plating of through hole, blind hole and circuit

A blind hole and circuit technology, applied in the field of copper plating solution, can solve the problem of not seeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The ratio of copper plating solution is as follows:

[0017] Copper Methanesulfonate 200g / L

[0018] Methanesulfonic acid 30g / L

[0019] Hydrochloric acid 50mg / L

[0020] Accelerator 0.7mL / L

[0021] Inhibitor 10mL / L

[0022] Leveling agent 15mL / L

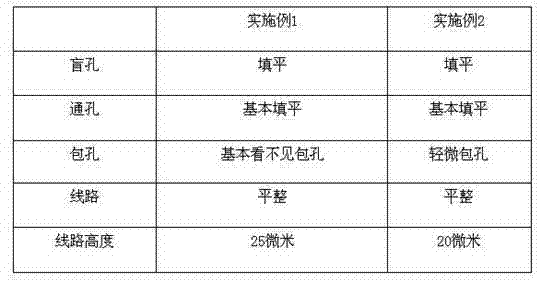

[0023] The methanesulfonic acid system copper plating solution prepared by the above scheme adopts 0.5ASD and the electroplating time is 4h. The results obtained are shown in Table 1: the blind hole is filled and the through hole is basically filled and leveled. , the line height is 25μm, without bottom copper.

Embodiment 2

[0025] The copper plating solution of methanesulfonic acid system prepared by the above scheme also adopts 0.7ASD, and the electroplating time is 3h. Flat, the line height is 20μm, without bottom copper.

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com