Kelly bar plug valve with floating valve seat

A technology of kelly and cock valves, which is applied in the field of kelly cock valves and drilling blowout prevention tools. It can solve the problems of reducing the life of cock valves, large pressure difference at both ends of the valve ball, and sediment clogging, so as to avoid high-pressure contact , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

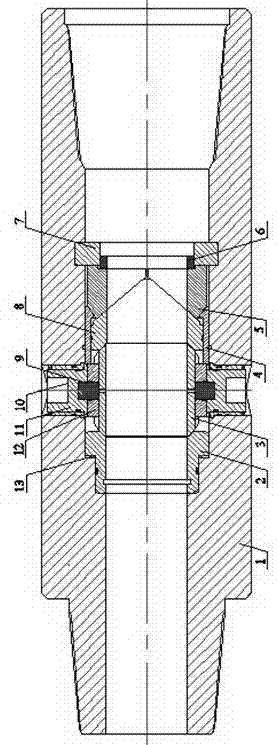

[0013] attached by figure 1 It can be seen that the plug valve includes a valve body (1), a lower valve seat (2), a valve ball (3), a top ring (4), a wedge block (5), a retaining ring (6), and a half ring (7) , wedge-shaped upper valve seat (8), fixed pin (9), rotary rod (10), valve sleeve (11), ten bytes (12), wave spring (13) and other seals. The rotating rod (10) is connected together with the valve ball (3) by ten joints (12). The top of the valve ball (3) is followed by a wedge-shaped upper valve seat (8), a wedge-shaped block (5), a half-ring (7) and a retaining ring (6). The lower part of the valve ball (3) is the lower valve seat (2). Under the action of the wave spring (13), the lower valve seat (2) and the valve ball (3) are closely fitted, and the lower valve seat (2) is located on the on the step of the valve body (1).

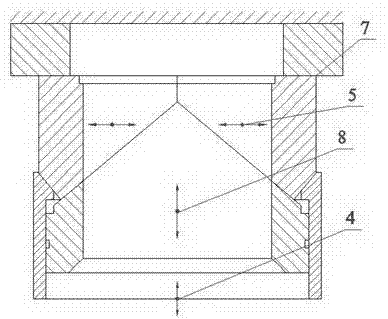

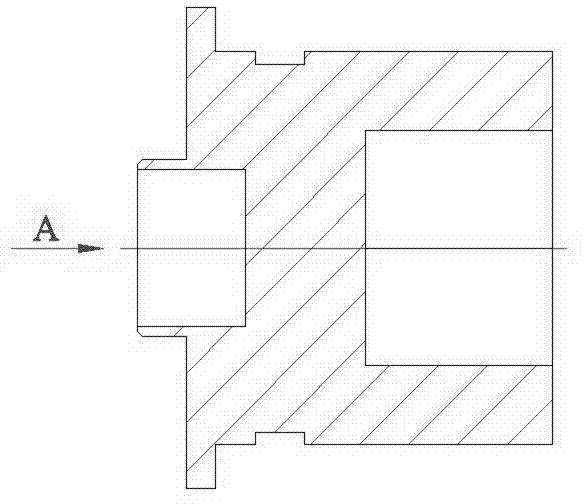

[0014] as attached image 3 , 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com