Turbine structure

A turbine and turbine blade technology, applied in the field of turbine structure, can solve the problems of high production cost, difficult maintenance, large gap, waste, etc., and achieve the effect of improving work efficiency and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

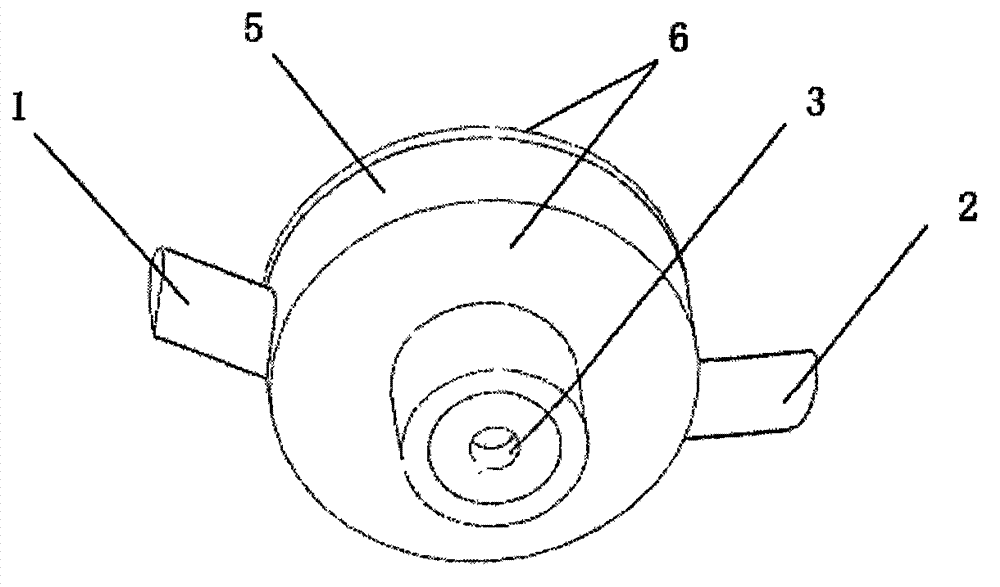

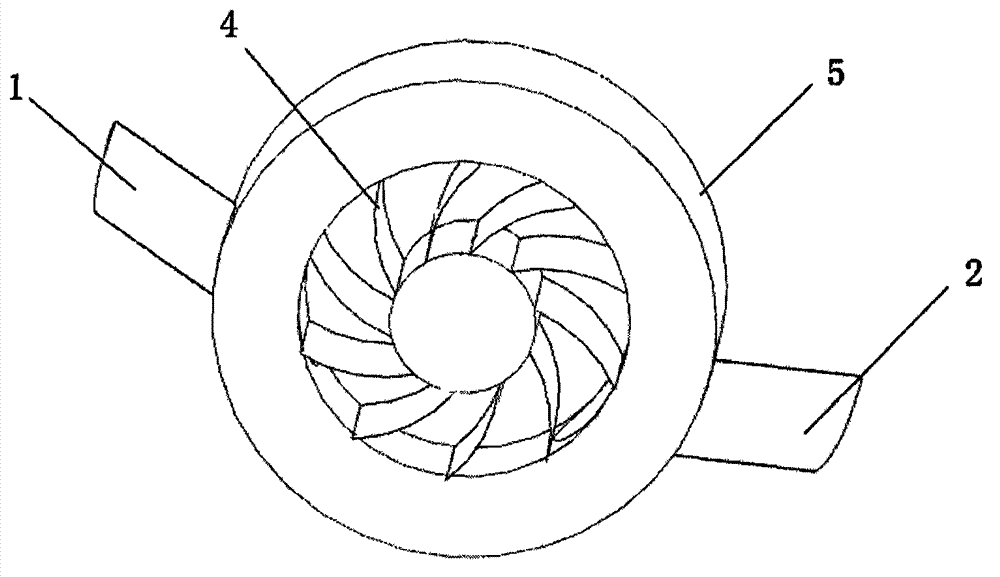

[0011] Such as figure 1 and figure 2 As shown, a turbine structure is composed of an annular casing 5 and two side end covers 6 to form a closed cavity, and a turbine blade 4 is installed inside the closed cavity, and the inner center of the turbine blade 4 is assembled with the rotating shaft 3 connection, the outer edge of the turbine blade 4 is rotated and attached to the inner wall of the annular casing 5 or the end covers 6 on both sides, and an energy inlet 1 is provided at one place on the closed cavity, and an energy inlet 1 is provided on the closed cavity. 1 is provided with an energy outlet 2 opposite to the other.

Embodiment 2

[0013] A turbine structure, a closed cavity is formed by an annular shell 5 and two side end covers 6, and a turbine blade 4 is installed inside the closed cavity, and the inner center of the turbine blade 4 is assembled and connected with the rotating shaft 3, and the turbine The outer edge of the blade 4 rotates and fits with the inner wall of the annular shell 5 and the end caps 6 on both sides. An energy inlet 1 is provided at one place on the closed cavity, and an energy inlet 1 is provided on the closed cavity opposite to the energy inlet 1. Another place is provided with energy outlet 2.

[0014] When working, water or steam enters the angular opening of the turbine blade from the energy inlet 1. Since the outer edge of the turbine blade 4 is in contact with the inner wall of the annular casing 5, the water or steam pushes the turbine blade 4 to rotate. When water or When the steam rotates to the energy outlet 2 along with the turbine blade 4, the water or steam is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com