A Deep Well Double Tube High Suction Jet Centrifugal Pump

A double-tube high-suction, centrifugal pump technology, applied in jet pumps, pumps, pump devices, etc., can solve the problems of small water volume of deep well pumps, insufficient water pressure, small water output from water outlet pipes, etc., and achieve high pump water height. , The effect of high pump water volume and deep suction stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

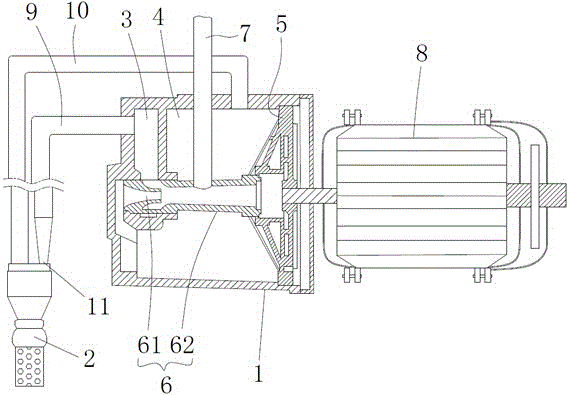

[0030]As shown in the figure, a deep well double-pipe high-suction jet centrifugal pump includes a pump body 1 and a jet pump 2 connected to the pump body 1, and the pump body 1 includes a water inlet chamber 3 and a water outlet chamber 4 , the water outlet chamber 4 is provided with an impeller 5, and the pump body 1 is also provided with a first fluidizer 6, and the water inlet of the water inlet chamber 3 and the impeller 5 are connected through the first fluidizer 6, The pump body 1 also includes a water outlet pipe 7 , and the water outlet pipe 7 is connected to the internal flow channel of the first ejector 6 . When the deep well double-pipe high-suction jet centrifugal pump of the present invention is working, the jet pump 2 is located in the deep well, and the motor 8 drives the impeller 5 in the water outlet chamber 4 to rotate, and the inside of the water outlet chamber 4 has a high-pressure water flow under the action of the impeller 5, And because the water outlet...

Embodiment 2

[0036] When the motor 8 is a single-phase motor, the power of the motor 8 is 2.2KW, the diameter of the impeller 5 is 160mm, the width of the water outlet of the impeller 5 is 6mm, the diameter of the injection port of the first jet 6 is 8mm, and the diameter of the second jet 11 when the diameter of the injection port is 4mm. It is found through tests that under this structural size, the deep well double-pipe high-suction jet centrifugal pump of the present application can achieve a maximum suction lift of 36m and a maximum lift of 28m. When the suction lift is 36m, the flow rate at outlet pipe 7 is 2.3 m 3 / h.

Embodiment 3

[0038] When the motor 8 is a single-phase motor, the power of the motor 8 is 2.2KW, the diameter of the impeller 5 is 160mm, the width of the water outlet of the impeller 5 is 10mm, the diameter of the injection port of the first jet 6 is 12mm, and the diameter of the second jet 11 when the diameter of the injection port is 6mm. It is found through tests that under this structural size, the deep well double-pipe high-suction jet centrifugal pump of the present application can achieve a maximum suction lift of 36m and a maximum lift of 28m. When the suction lift is 36m, the flow rate at outlet pipe 7 is 3.0 m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com