TLGF-HY-90-III type energy-saving material conveying fan

A technology of TLGF-HY-90-III, 1. TLGF-HY-90-III, applied to liquid fuel engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problem of high power consumption of wind turbines , affect the surrounding environment, non-compliance and other issues, to achieve the effect of less power efficiency, faster transmission process, and higher efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

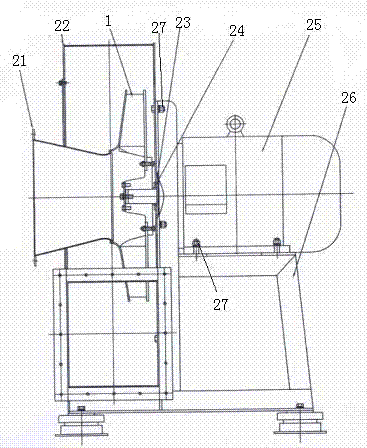

[0013] As shown in the figure, the TLGF-HY-90-Ⅲ energy-saving material conveying fan includes a frame 26, a casing 22, a motor 25, an impeller 1 and an air inlet ring 21, and the casing 22 is located above the frame 26 , the bottom of the motor 25 is fixed on the base 26 by bolts 27, the side of the motor 25 is fixedly connected to the casing 22 by bolts 27, and a sealing cover 23 is provided between the casing 22 and the motor 25, A dustproof cover 24 is provided on one side of the sealing cover 23 , the impeller 1 is arranged in the casing 22 , and the air inlet ring 21 is fixedly connected with the impeller 1 .

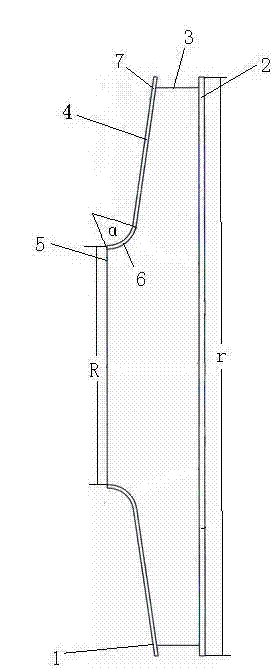

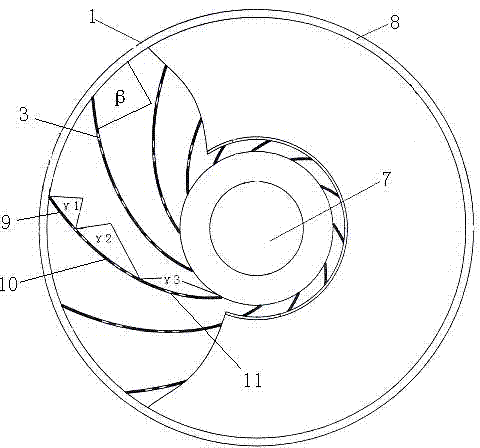

[0014] The above-mentioned TLGF-HY-90-III energy-saving material conveying fan, wherein, the impeller 1 includes a front disk 7, a rear disk 2 and blades 3, and the front disk 7 includes an expansion and contraction surface 4 and an air inlet 5. The expansion and contraction surface 4 and the air inlet 5 are connected into an integrated structure through a transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com