A Method for Optimizing the Setting Value of Partition Pressure in Hydraulic Propulsion System of Roadheader

A propulsion system and optimization method technology, applied in the direction of mechanical equipment, fluid pressure actuators, mining equipment, etc., can solve the problems of dependence, low efficiency, large error, etc., achieve simplified control, improve the ability of trajectory tracking, and solve the problem of trajectory Tracking the effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

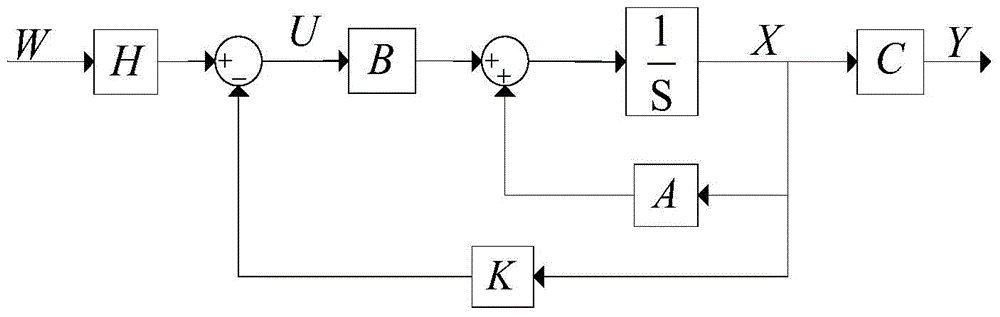

[0050]Taking the excavation trajectory control of the excavation machine as an example, the optimization of the pressure setting value of the hydraulic propulsion system of the excavation machine provided by the present invention is described in detail.

[0051] The symbols appearing in the drawings and some formulas and the physical quantities represented by the symbols are shown in Table 1:

[0052] Table 1

[0053]

[0054]

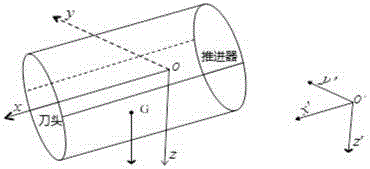

[0055] like figure 1 As shown, two coordinate systems are used when building the dynamic model of the roadheader: geographic coordinate system and fuselage coordinate system. O-xyz represents the fuselage coordinate system, and O'-x'y'z' represents the geographic coordinate system. The geographic coordinate system is usually considered an inertial coordinate system.

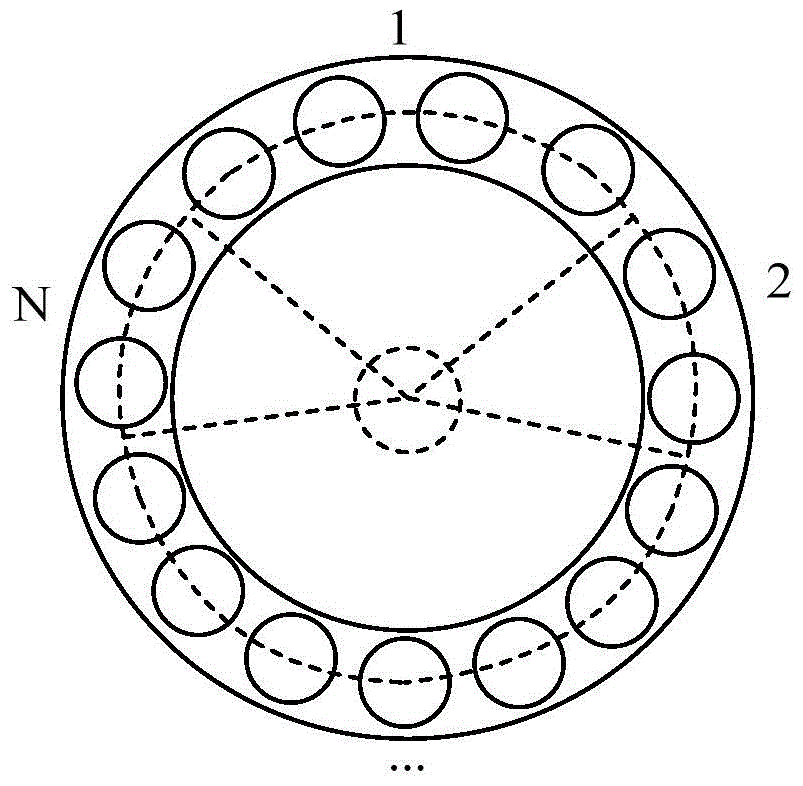

[0056] like figure 2 As shown, the hydraulic cylinders of the hydraulic propulsion system of the roadheader are evenly distributed in the shield head, and the hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com