Movable LED backlight device

A backlight device and mobile technology, applied in lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve problems such as inability to disperse, limited use of light source brightness for large-area panels, poor performance, etc., to reduce heat generation, The effect of reducing the number of LEDs and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A mobile LED backlight device of the present invention will be further described below with reference to the accompanying drawings.

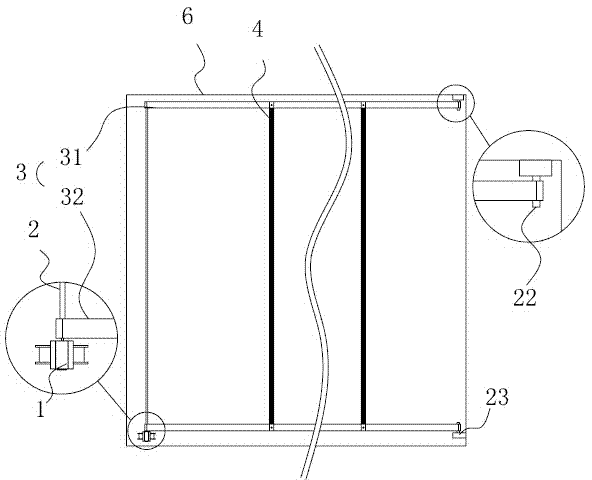

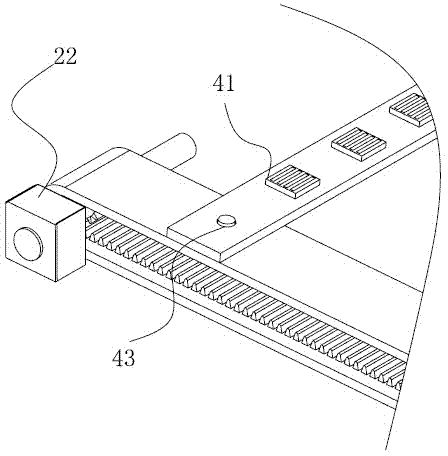

[0021] A mobile LED backlight device for providing backlight for display screens, such as figure 1 As shown, it includes: a motor 1, a rotating rod 2 connected to the rotor of the motor 1, a conveyor belt 3 driven by the rotating rod 2 through a linkage structure, at least one LED light bar 4 installed on the conveyor belt 3, and a For the housing 6 that accommodates and fixes the above components, the LED light bar 4 has two opposite light-emitting surfaces.

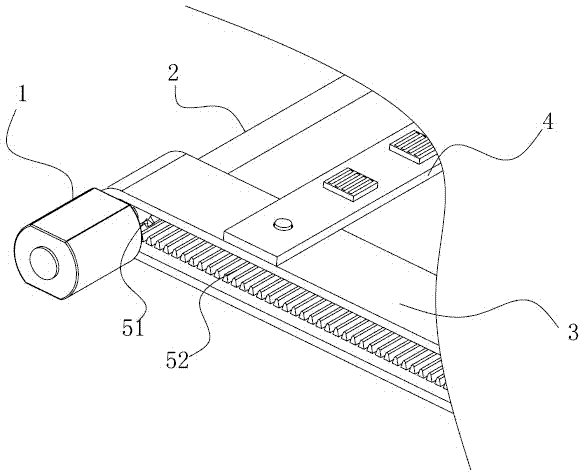

[0022] Specifically, such as figure 2 As shown, the motor 1 is a high-speed brushless motor, which can reduce the noise while ensuring the speed. The tail of the rotating rod 2 is directly connected to the rotor of the motor 1 or linked with the motor through a gear structure. When the rotor of the motor 1 rotates, the rotating rod 2 rotates accordingly, and the conveyor belt 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com