A gear single tooth loading test device with load equalization function

A technology of loading test device and gear unit, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as large errors, lack of basic test data, constraints of high-end gear products, etc., to reduce discreteness, clear loading position, suitable for Object wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiments (accompanying drawings).

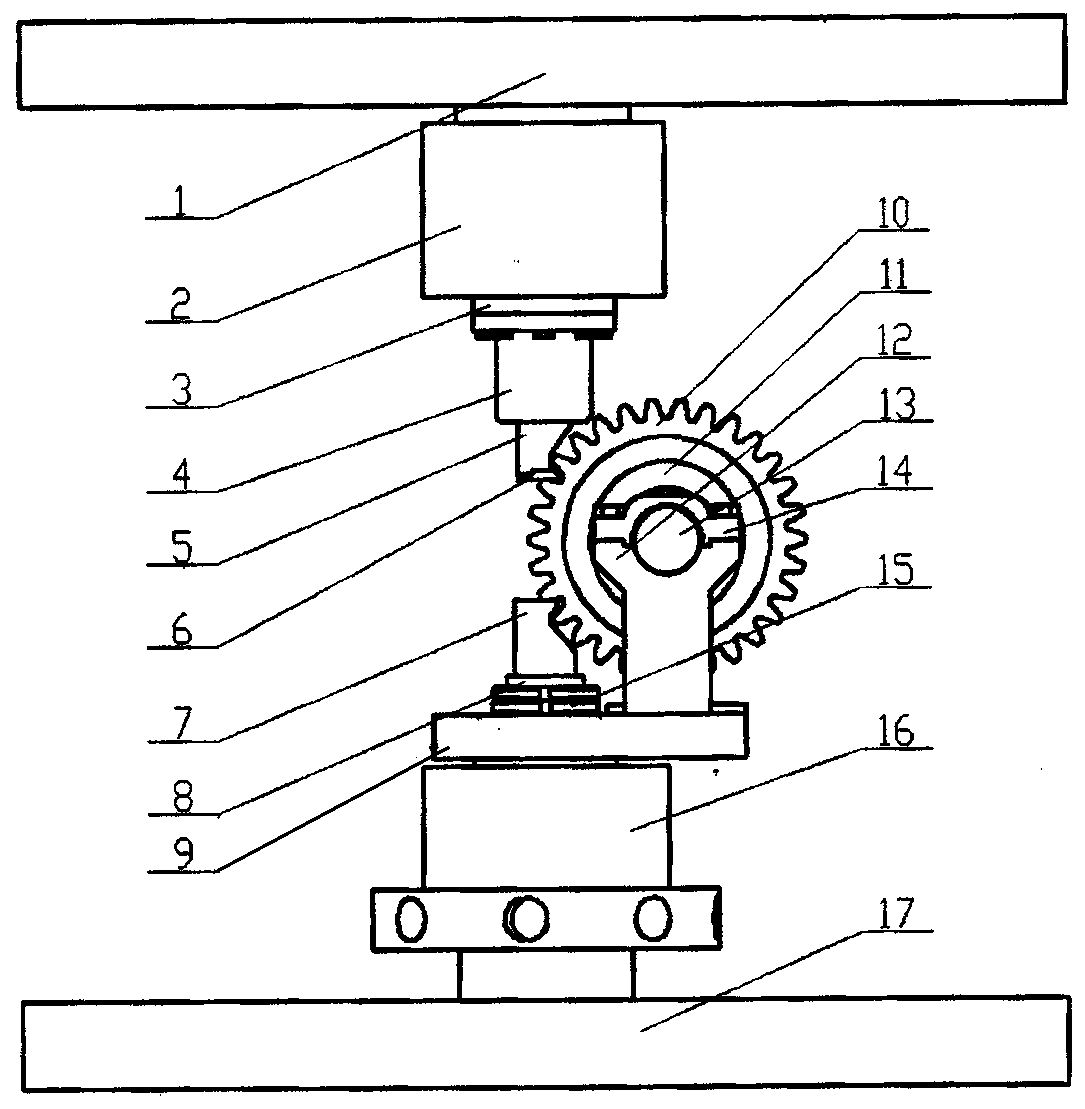

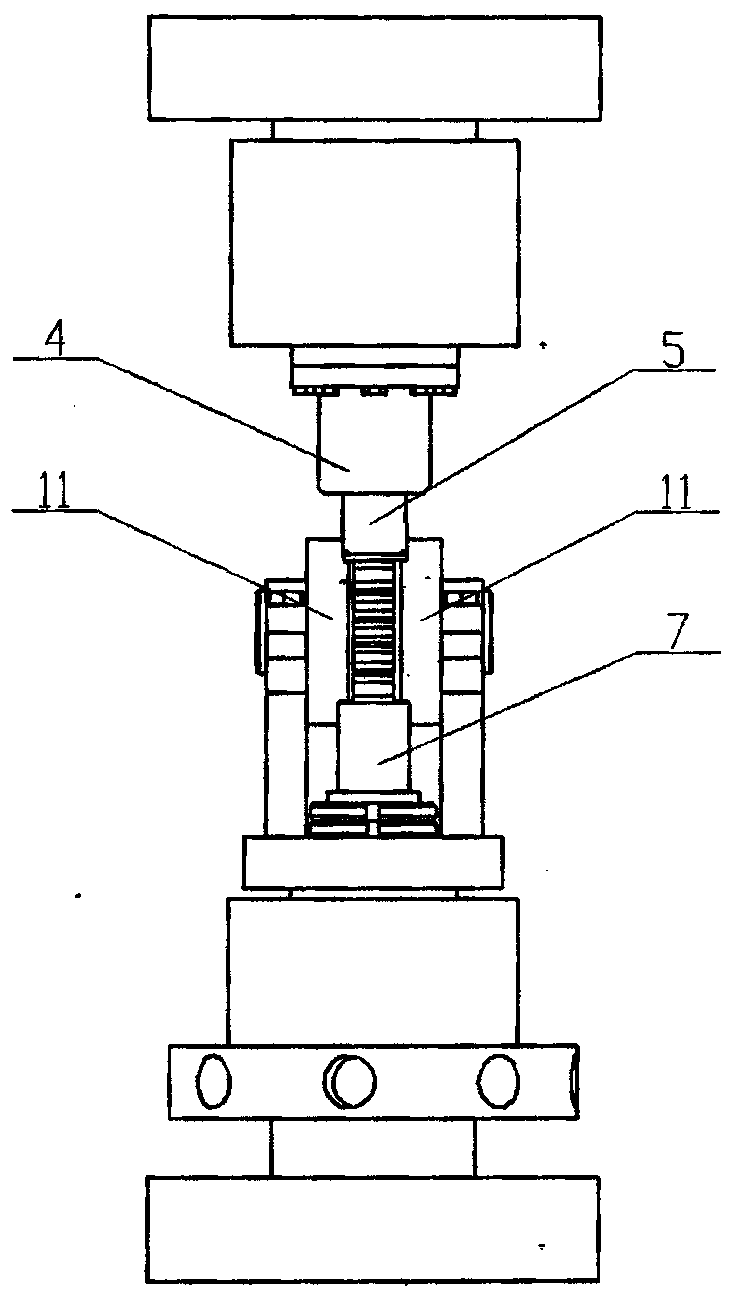

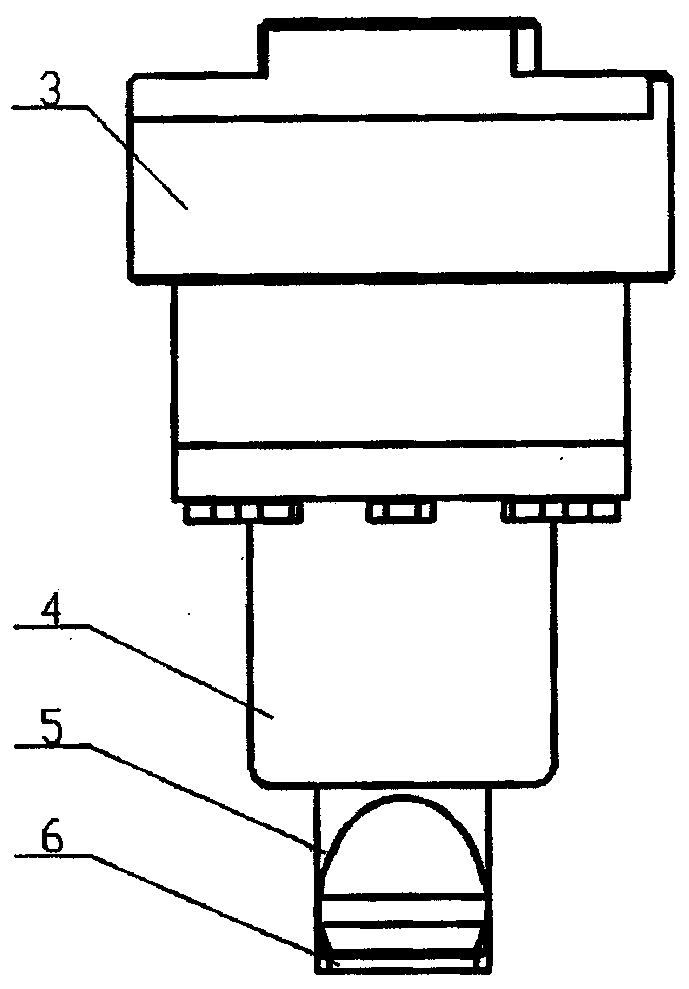

[0028] Such as figure 1 and figure 2 As shown, the gear single-tooth loading test device with load equalizing function of the present invention includes two parts: a support structure and a loading structure located above the support structure; , positioning ring 11, support frame 12, mandrel 13, shaft gland 14; the lower end of the support head 7 is fixed on the support base 9; 15 The fixed plate 12-2 fixedly installed on the support base 9, the adjustable support 12-1 installed in the guide groove processed on the fixed plate, the positioning pin 12-1 arranged between the fixed plate and the adjustable support 3 and deadbolt 12-4 (see Figure 8-10 ); the supporting base 9 is integrated with the lower bed 17 through the large nut 16 of the lower bed, and the test gear 10 is installed on the top of the adjustable bracket 12-1 through the positioning ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com