A Rapid and Effective Method for Extracting Oil from Cottonseed in Early Development

An extraction method and cottonseed technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problem of little correlation between fatty acid accumulation and dynamic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1, Cottonseed Sampling in Early Development

[0017] Mark the cotton when it blooms, and mark the flowering date, select plants with the same flowering period, mark the flowers that bloom on the same day on the main inflorescence and the first branch inflorescence, and take cotton seeds at the early stage of development 5 and 10 days after flowering Cottonseed samples in each stage were tested three times for each sample.

Embodiment 2

[0018] Embodiment 2, the oil extraction of early stage cottonseed

[0019] Use tweezers to take out the cottonseeds from the bolls, gently peel off the shell of the cottonseeds, etc., take out the cottonseeds and collect them in a 50ml centrifuge tube, freeze them quickly in liquid nitrogen, and store them in a -80°C ultra-low temperature refrigerator.

[0020] Take out the frozen cotton kernel sample, grind it into powder with liquid nitrogen, take 10 μg and put it into a 1.5ml centrifuge tube, add 0.6ml of chloroform-methanol (volume ratio 2:1) mixed solvent, at 40 ℃, 200r / min After 4 hours of treatment on a shaker, centrifuge at 6000r / min for 10 minutes.

[0021] Weigh the weight of the 1.5ml centrifuge tube with constant weight, then absorb the lower oil phase layer into the centrifuge tube, evaporate to dryness on a rotary vacuum dryer at 25°C to constant weight, weigh, subtract the centrifuge tube, and calculate the oil yield up to 30%.

[0022] In the above centrifuge...

Embodiment 3

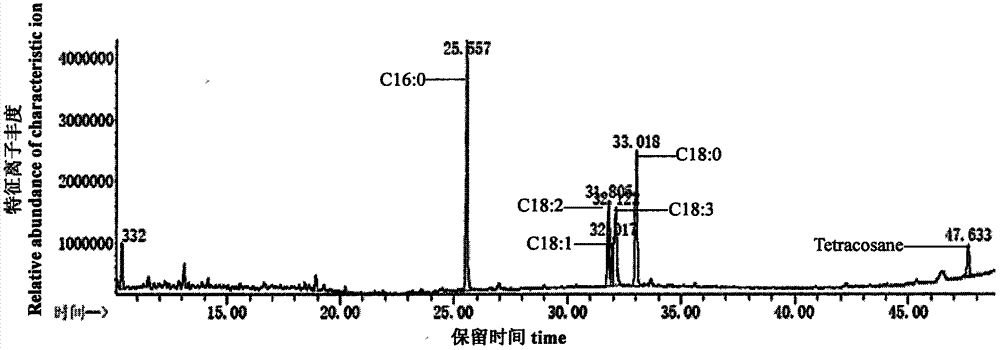

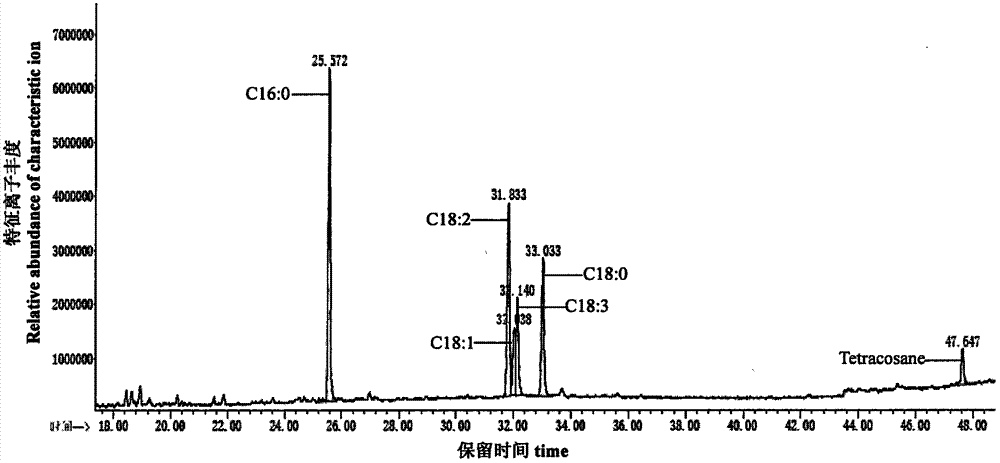

[0024] Embodiment 3, the GC-MS analysis of cottonseed fatty acid component

[0025] Agilent Technologies 7890A GC System was used for GC-MS analysis, chromatographic column HP-5MS19091S-436 (60m×250μm×0.25μm); injection volume 1μL, split injection method, split ratio 50:1; inlet temperature 250°C ; Carrier gas Ne, 20mL / min. Programmable temperature rise, keep at 150°C for 1min, then rise to 180°C at a rate of 10°C / min, keep for 5min, rise to 230°C at a rate of 3°C / min, keep for 15min, and then rise to 270°C, keep for 20min.

[0026] Gas chromatographic determination shows that, compared with C16:0, C18:0, C18:1, C18:2, C18:3 of mature cottonseed (the relative content is respectively: 25%, 2%, 15%, 57%, 0.2%) In contrast, the accumulation of C16:0, C18:0, and C18:3 fatty acid components in cottonseed was mainly concentrated in the early and middle stages of seed development; , the relative contents of C18:2 and C18:3 were: 34.94%, 21.86%, 7.45%, 14.51%, 15.87% respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com