Dynamic Rotary Sterilizer

A technology of dynamic rotation and sterilization cabinet, applied in the field of sterilization cabinet, can solve problems such as being unsuitable for mass production, affecting product quality, limiting sterilization effect, etc., to achieve strong sterilization effect, improve sterilization quality, and convey materials good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

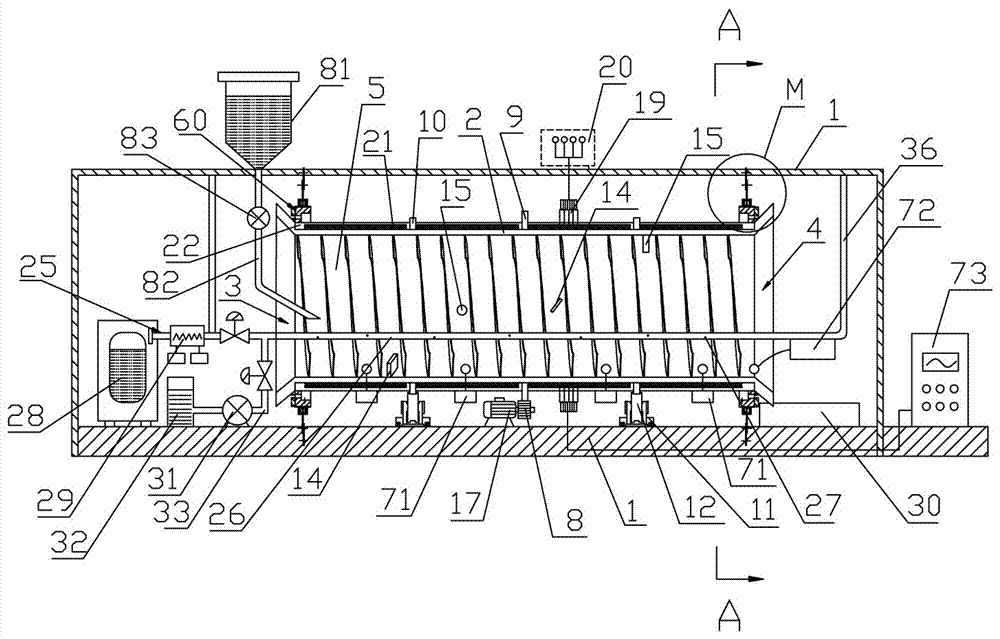

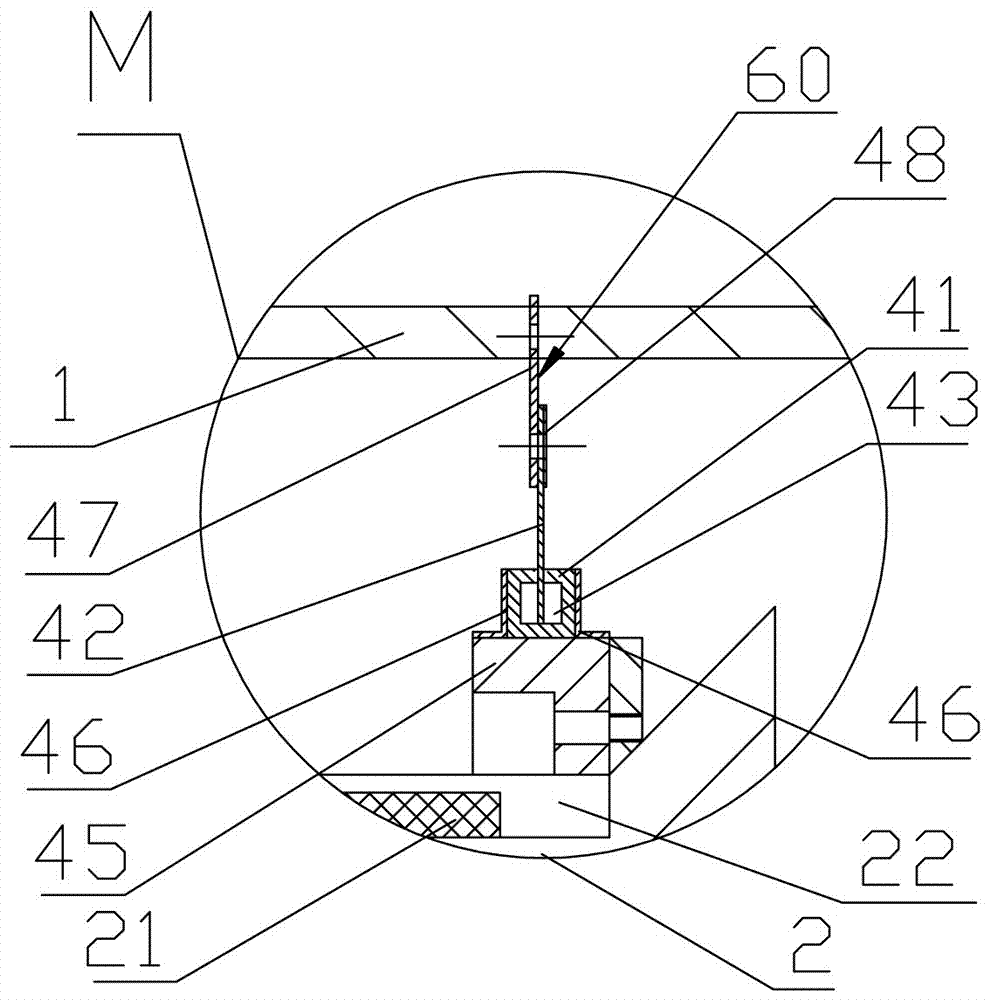

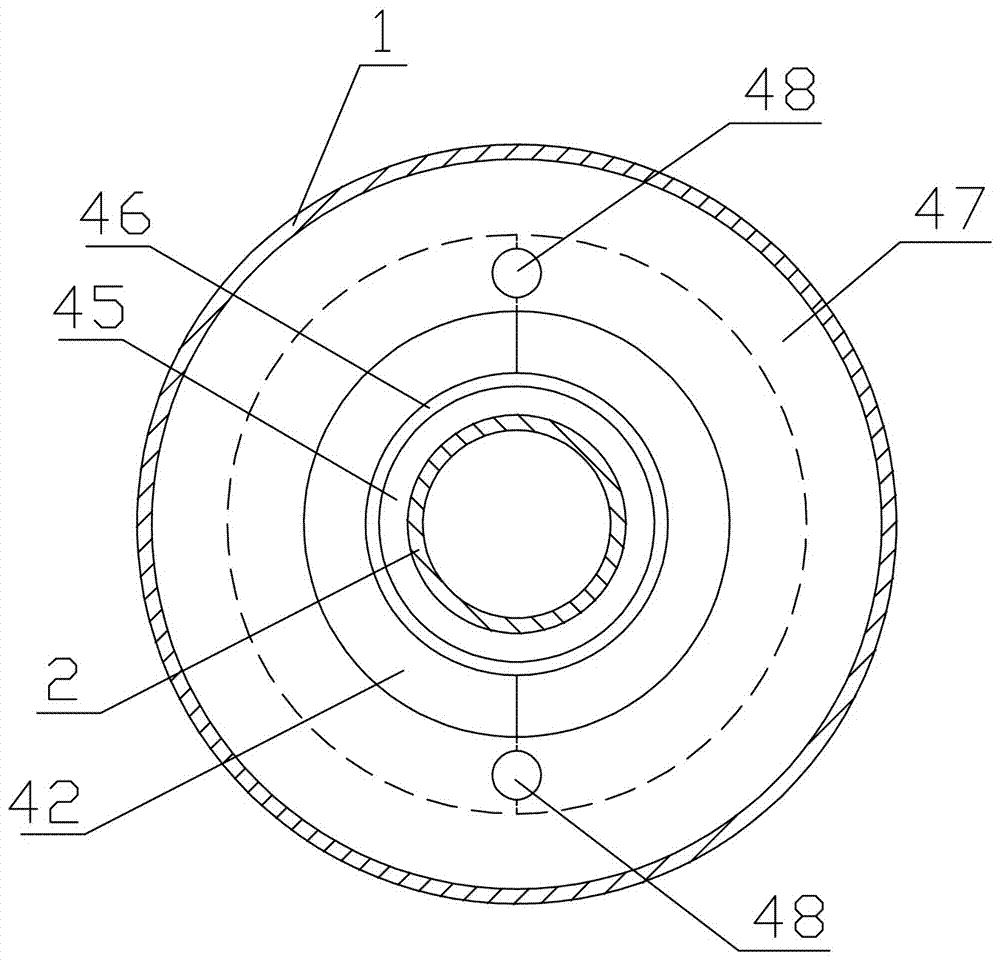

[0019] Such as figure 1As shown, the dynamic rotary sterilizer includes: a casing 1 and a cylinder 2 installed in the casing 1, and the two ends of the cylinder 2 are respectively provided with a feed inlet 3 and an outlet for materials to enter and exit the cylinder 2. The material port 4 is provided with a spiral guide groove 5 on the inner wall of the cylinder body 2, which can transport the material from the material inlet 3 to the material discharge port 4. The cylinder body 2 is movably supported in the casing 1 and is connected with the The drive assembly on the casing 1 is connected. Under the driving action of the drive assembly, the cylinder body 2 rotates around its own central axis, so that the material entering the rotating cylinder body 2 from the feed port 3 moves along the spiral guide groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com