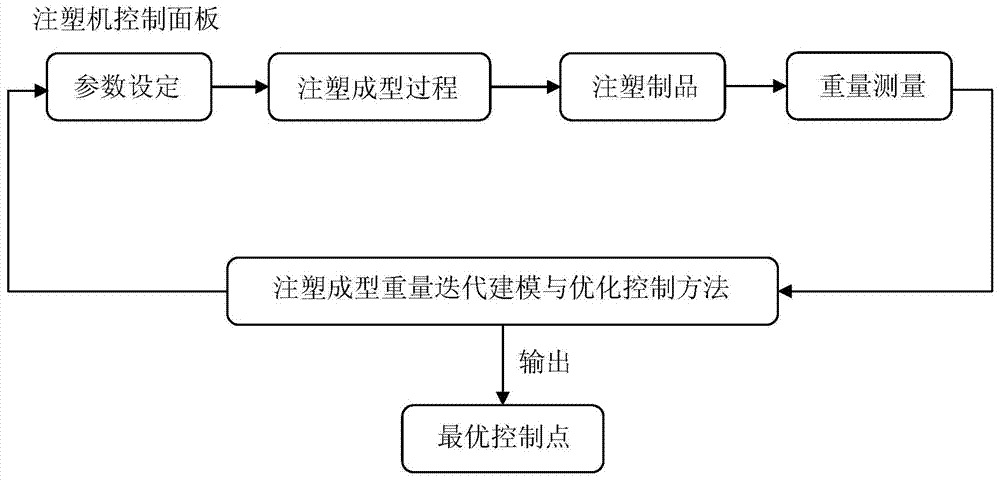

Product weight control method based on iteration modeling and optimization for injection molding process

A technology of injection molding and weight control, applied in the field of weight control of injection molding products, can solve problems such as difficulty in convergence, and achieve the effect of saving optimization costs, strong practical operability, innovation and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

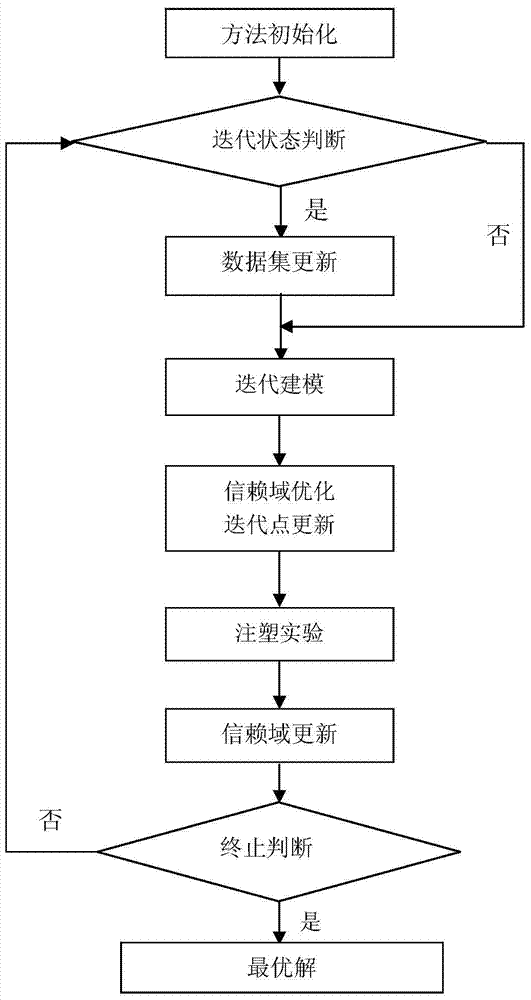

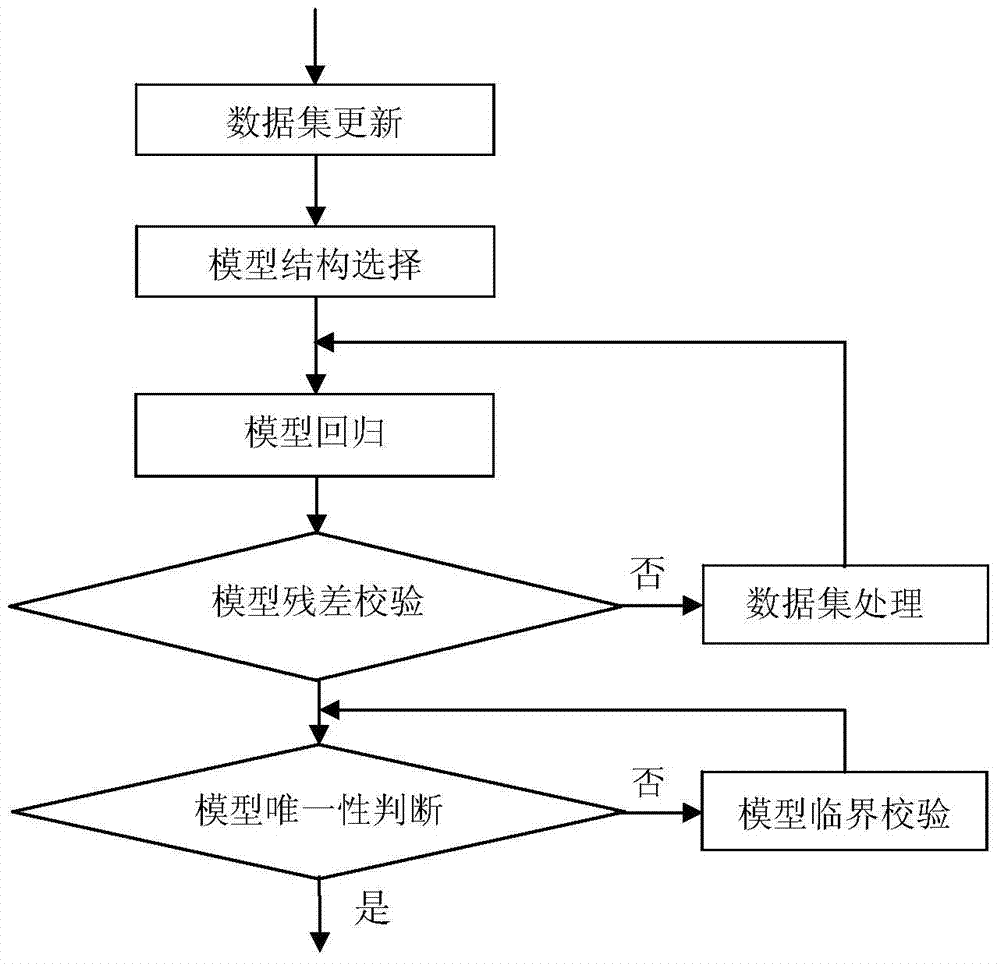

Method used

Image

Examples

Embodiment

[0038] The implementation process of a weight control method for iterative modeling and optimization of the injection molding process proposed by the present invention will be described below by taking the weight control of a plastic lens as an example.

[0039] First, enter step (1) to collect data and initialize parameters; the weight control target W of the product is tg =7.83 grams, according to the weight fluctuation of the product, set the weight deviation tolerance τ=0.005 grams, the modeling data upper limit U is set to 20, the model residual tolerance C is set to 2, and the trust region related parameters {ρ,λ,ε ,μ} is set to a constant value; the optimized operating variables are: injection speed, holding pressure and holding time, where the injection section is divided into one section and two sections for control respectively, and the subsection point is also a key process parameter . In this way, a total of 5 process parameters need to be adjusted in the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com