Tung oil polyol base post-crosslinkable amphoteric polyurethane and preparation method thereof

A technology of polyurethane and tung oil, which is applied in the field of ionic polyurethane, tung oil polyol-based amphoteric polyurethane and its preparation, can solve the problems such as the preparation method of amphoteric water-based polyurethane that have not yet been seen, achieve good acid-base reversibility, improve utilization rate, and reduce dependence sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

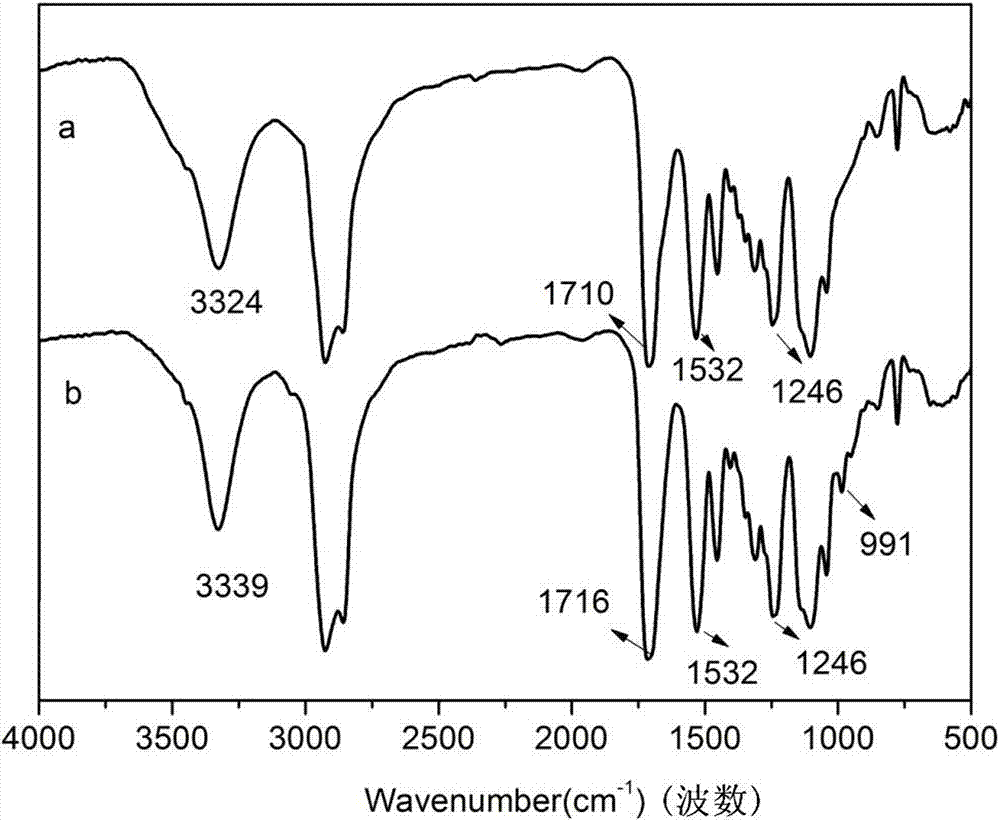

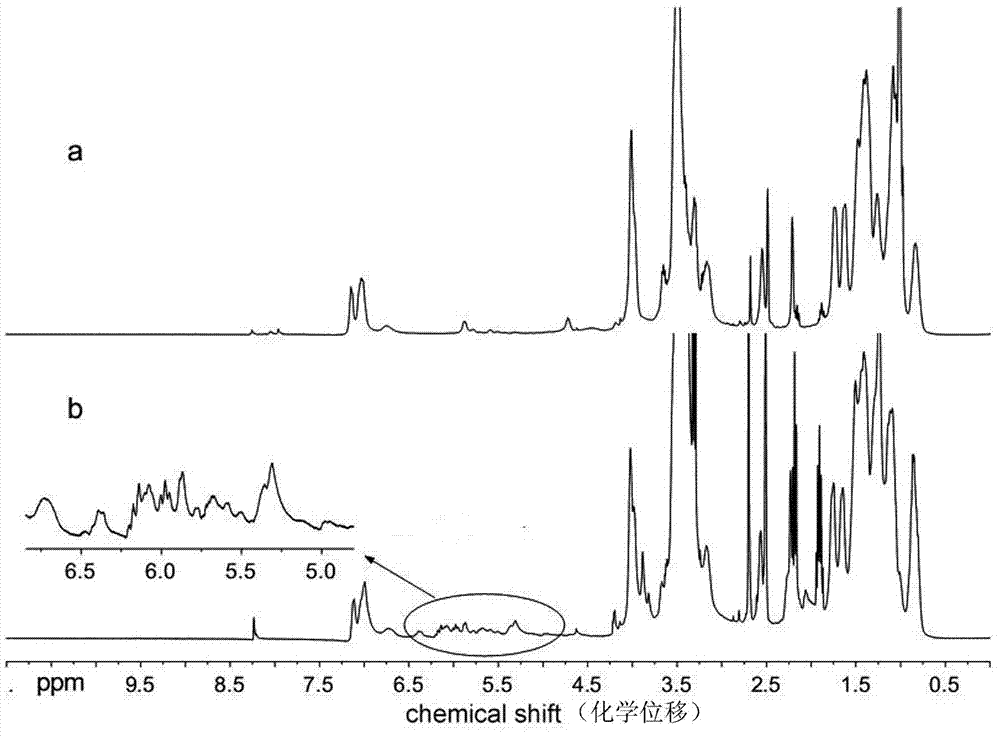

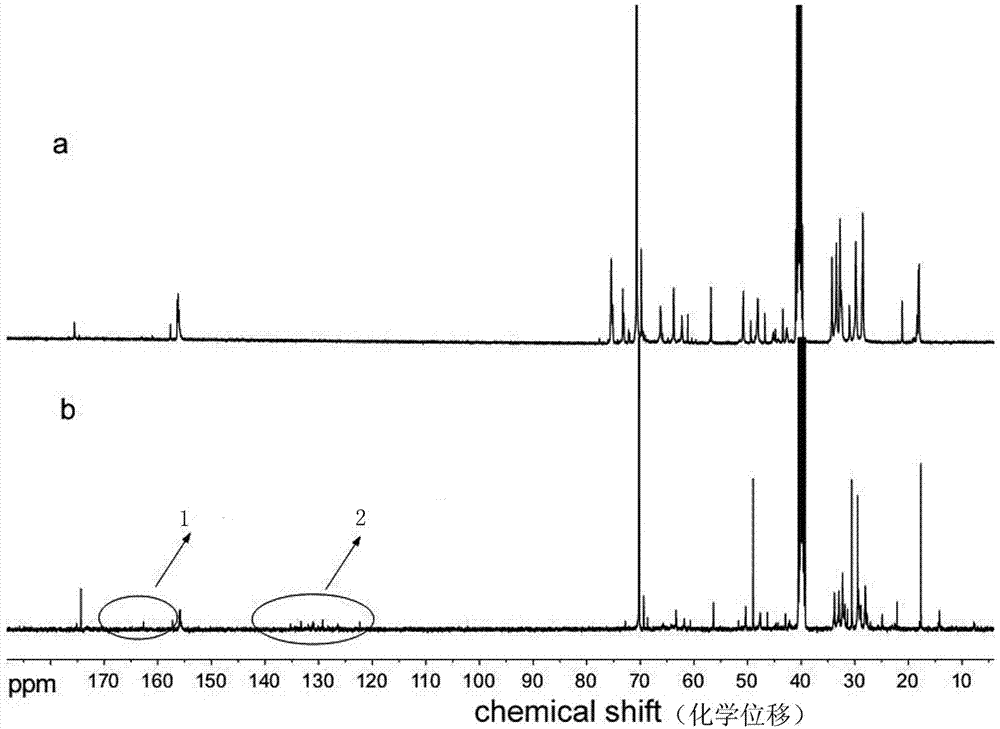

[0036] Embodiment 1: Synthesize tung oil polyol-based amphoteric polyurethane from isocyanate by HMDI

[0037] After fully drying the reaction device, add polyoxyethylene ether (PEG-800) with a molecular weight of 800 to the four-necked bottle, remove water in a vacuum and cool down to room temperature, add 4,4'-dicyclohexyl under nitrogen protection and stirring Methane diisocyanate (HMDI) and heated to 90 ° C, add dimethylol propionic acid (DMPA) to dissolve and cool down, add tung oil polyol (TG-20C) and N-methyldiethanolamine (MDEA), slowly heat up to 90 ℃ reaction 2.5h. When the NCO reaches the theoretical value, cool the product with adjusted viscosity, add acetic acid, add distilled water after 20 minutes of neutralization, stir and mix and discharge the material, so that the amphoteric compound based on tung oil polyol and HMDI with a solid content of 25% can be prepared. Polyurethane.

[0038] The proportioning ratio of the main raw materials is the molar ratio of D...

Embodiment 2

[0039] Embodiment two: change the isocyanate from HMDI to hexamethylene diisocyanate (HDI)

[0040] After fully drying the reaction device, add PEG-800 to the four-neck bottle, remove water in vacuum and cool down to room temperature, add HDI under nitrogen protection and stirring, heat to 90°C under stirring, add DMPA to dissolve and cool down, add TG-20C and MDEA were heated slowly to 90°C for 3.5 hours. After the reaction, cool the product with adjusted viscosity, add acetic acid for neutralization for 20 minutes, add distilled water, stir and mix and discharge the material, so as to obtain an amphoteric polyurethane based on tung oil polyol and HDI with a solid content of 25%.

[0041] The molar ratio of DMPA:MEDA:PEG:HTO:HDI=2:2:4:3:11

Embodiment 3

[0042] Embodiment three: isocyanate is changed into isophorone diisocyanate (IPDI) by HMDI

[0043] After fully drying the reaction device, add PEG-800 to the four-necked bottle, remove water in vacuum and cool down to room temperature, add IPDI under nitrogen protection and stirring and heat to 90°C, add DMPA and stir to dissolve and cool down, then add TG-20C and MDEA, slowly warming up to 85°C for 2.5h. After the reaction is finished, cool the product with adjusted viscosity, add acetic acid to neutralize for 20 minutes, add distilled water, stir and mix and discharge, thus the amphoteric polyurethane based on tung oil polyol and IPDI with a solid content of 25% can be prepared.

[0044] The molar ratio of DMPA:MEDA:PEG:HTO:IPDI=3:3:3:3:12

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com