Interface treatment method for horizontal construction seam of concrete

A technology for horizontal construction joints and interface treatment, applied to building components, building insulation materials, etc., can solve the problems of construction noise, surrounding environment impact, labor and time-consuming operation, and pollution of the construction environment, so as to achieve good construction effect, good treatment effect, The effect of short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for interface treatment of concrete horizontal construction joints, comprising the steps of:

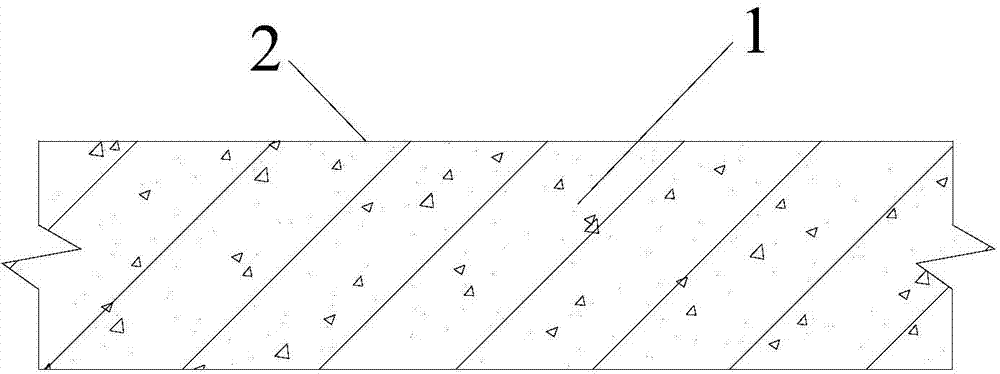

[0026] 1) if figure 1 As shown, the concrete is poured to form the first pouring concrete 1 and the natural forming interface 2 of the horizontal construction joint;

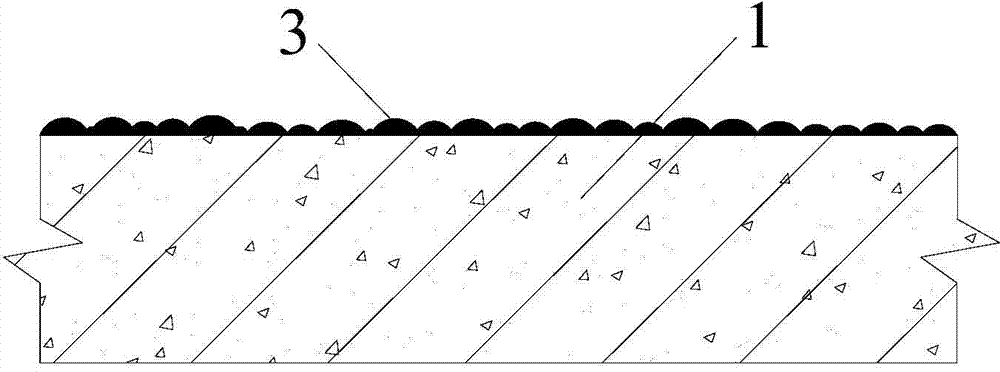

[0027] 2) if figure 2 As shown, when the first poured concrete reaches initial setting, concrete retarder 3 is sprayed on the natural forming interface of concrete horizontal construction joints. Concrete retarder 3 is lignosulfonate retarder, and the spraying amount is 200g / m 2 ;

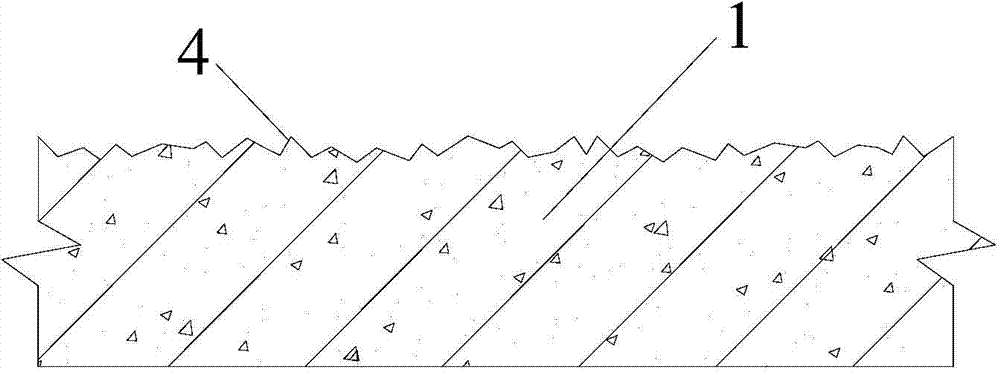

[0028] 3) if image 3 As shown, after spraying the lignosulfonate retarder for 10 hours, use a high-pressure water gun to wash the construction joint interface to remove the laitance retarder layer at the interface, so that the coarse aggregate at the interface is exposed, and the uneven interface treatment effect is achieved. , forming the interface 4 after construction joint treatment;

[0029] 4) When the concrete p...

Embodiment 2

[0031] A method for interface treatment of concrete horizontal construction joints, comprising the steps of:

[0032] 1) Concrete pouring, forming the first pouring concrete 1, and the natural forming interface 2 of the horizontal construction joint;

[0033] 2) When the first poured concrete reaches initial setting, spray concrete retarder 3 on the natural forming interface of concrete horizontal construction joints. Concrete retarder 3 is lignosulfonate retarder, and the spraying amount is 300g / m 2 ;

[0034] 3) After spraying the lignosulfonate retarder for 15 hours, use a high-pressure water gun to wash the construction joint interface to remove the laitance retarder layer at the interface, so that the coarse aggregate at the interface is exposed, and the uneven interface treatment effect is achieved. Form the interface 4 after the construction joint treatment;

[0035] 4) When the concrete poured for the first time reaches the specified curing time, the concrete is pour...

Embodiment 3

[0037] A method for interface treatment of concrete horizontal construction joints, comprising the steps of:

[0038] 1) Concrete pouring, forming the first pouring concrete 1, and the natural forming interface 2 of the horizontal construction joint;

[0039] 2) When the first poured concrete reaches initial setting, spray concrete retarder 3 on the natural forming interface of concrete horizontal construction joints. Concrete retarder 3 is lignosulfonate retarder, and the spraying amount is 400g / m 2 ;

[0040] 3) After spraying the lignosulfonate retarder for 20 hours, use a high-pressure water gun to flush the construction joint interface to remove the laitance retarder layer at the interface, so that the coarse aggregate at the interface is exposed, and the uneven interface treatment effect is achieved. Form the interface 4 after the construction joint treatment;

[0041] 4) When the concrete poured for the first time reaches the specified curing time, the concrete is pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com