A conveniently installed indoor insulation and sound insulation partition wall

A kind of thermal insulation and sound insulation, convenient technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult to rationally apply indoor space, poor thermal insulation performance, occupied space and other problems, to increase the aesthetics, building light weight, Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

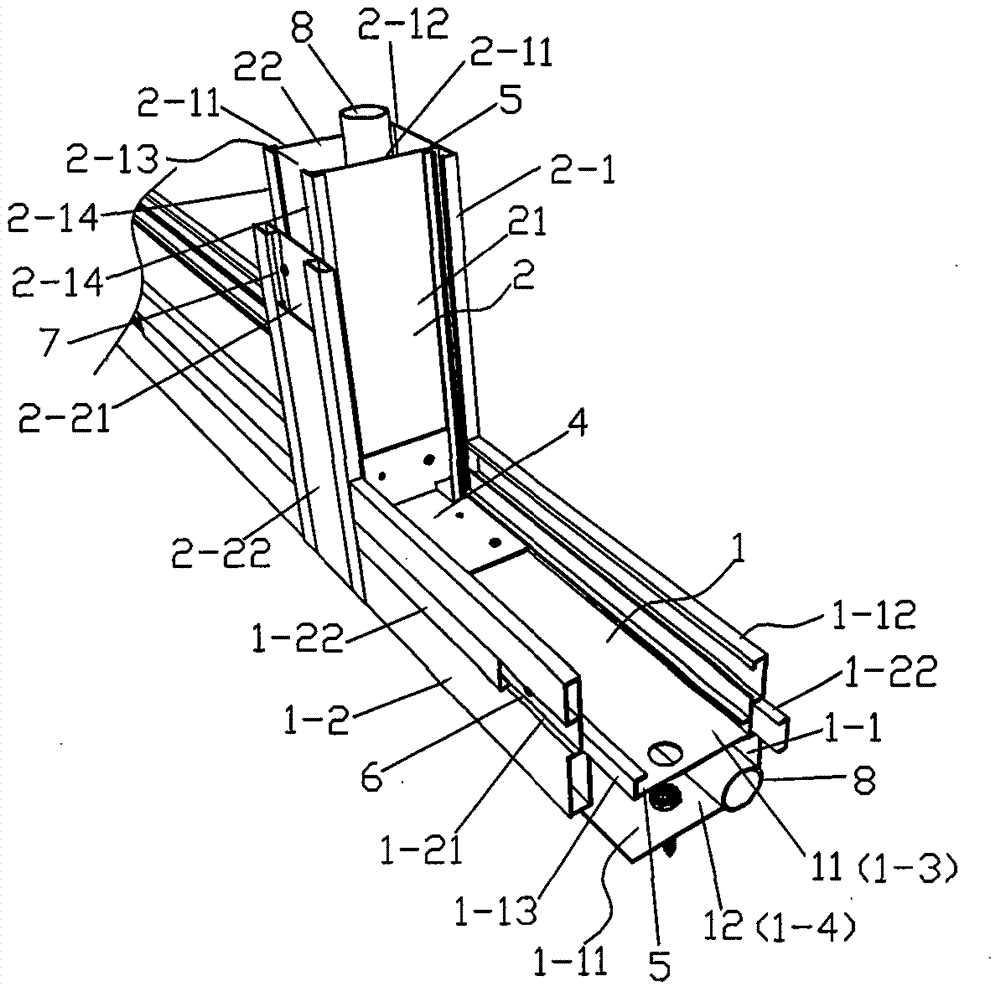

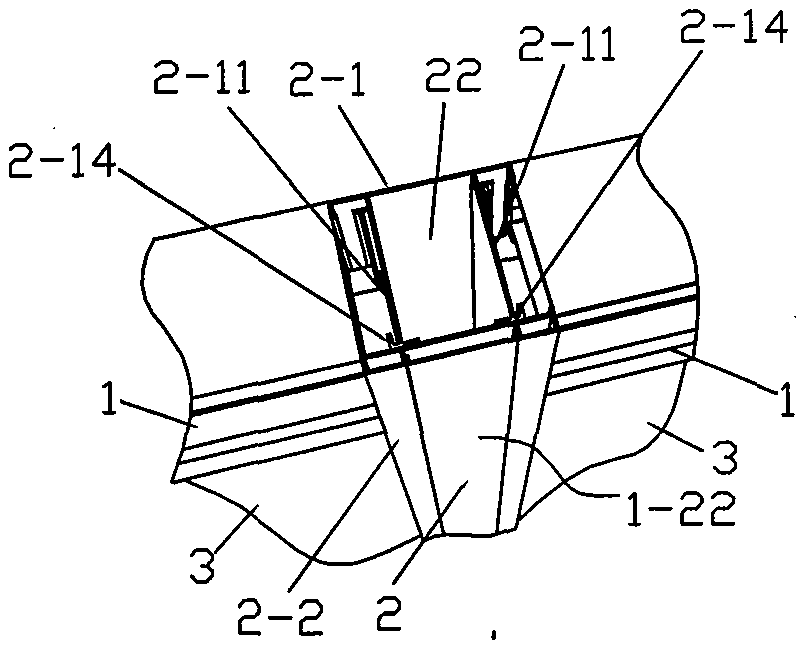

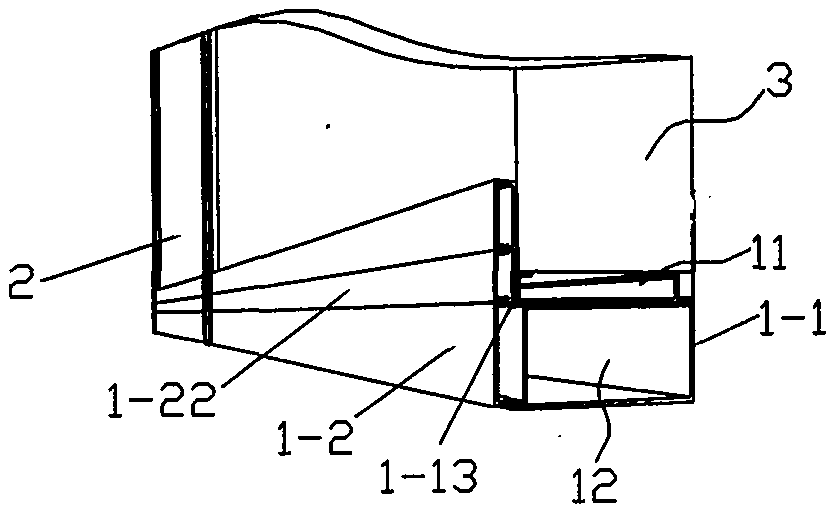

[0022] refer to Figure 1 to Figure 3 A conveniently installed indoor heat insulation and soundproof partition wall includes a beam 1, a central column 2 and a partition 3. The beam 1 is composed of a profile provided with a beam installation groove 11 and a beam line pipe 12. The center column 2 is composed of profiles provided with a center column installation groove 21 and a center column line pipe 22, the beam 1 is a lateral load-bearing beam of a partition wall, and the center column 2 is installed on the beam 1 to form the vertical direction of the beam 1. The support column, the partition plate 3 is installed on the beam installation groove 11 of the beam 1 and the center column installation groove 21 of the center column 2 to form a partition wall, the beam line pipe 12 of the beam 1 and the center column 2 of the beam The column pipes 22 communicate with each other to form a connecting channel for laying water pipes and power lines. The beam installation groove 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com