Separate-layer fracturing sand control string for thermal production well and sand control method thereof

A technology of layered fracturing and sand control pipes, which is applied in the direction of production fluid, earthwork drilling and flushing wellbore, etc. It can solve problems such as high construction risk, sudden pressure change, affecting oil well production and sand control validity period, etc., to ensure sand control effect, The effect of preventing vomiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

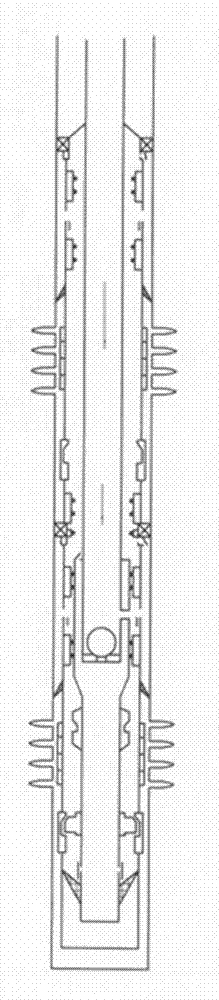

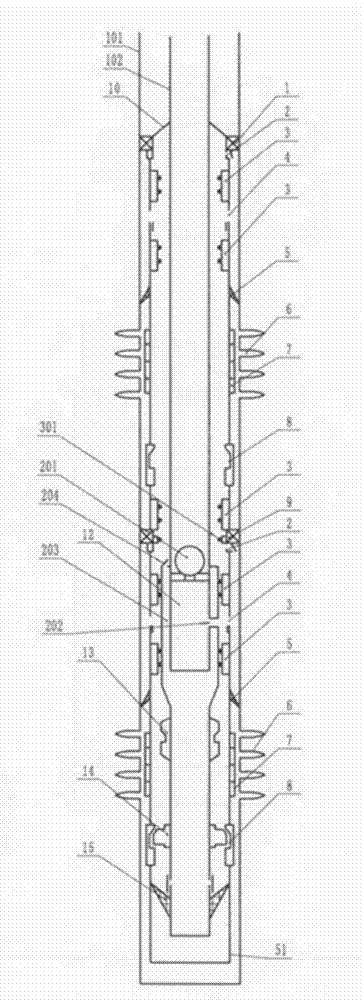

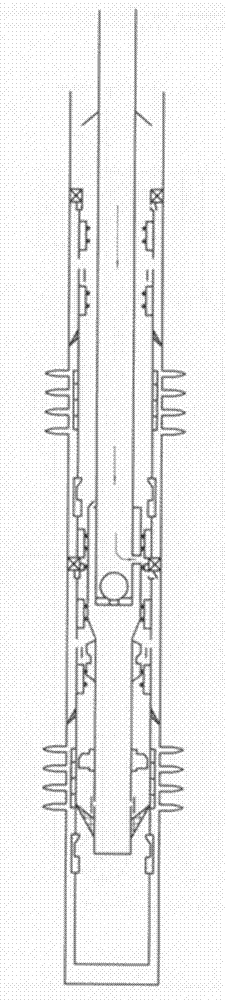

[0030] Sand control string for thermal recovery well layered fracturing, see figure 1 As shown, there are two layers of tubing strings including the sand control outer pipe and the process inner pipe. The sand control outer pipe is installed in the well section of the oil layer inside the casing 101, and the process inner pipe is installed in the sand control outer pipe. 10 Connect the sand control outer pipe and the process inner pipe together.

[0031] Sand control outer pipe connects top packer 1, backwash device 2, fracturing sealing tool 3, fracturing packing outer tool 4, fracturing sealing tool 3, one-way sealing tool 5, screen pipe 7, external positioning from top to bottom Device 8, fracturing sealing tool 3, interlayer packer 9, backwashing device 2, fracturing sealing tool 3, fracturing packing external tool 4, fracturing sealing tool 3, one-way sealing tool 5, screen pipe 7, Outer positioning device 8, silk plug 51.

[0032] The tools are connected through oil pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com