Biaxial stress high temperature creep deformation test apparatus

A high-temperature creep and test device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as the inability to meet the requirements of material bidirectional stress testing, and achieve the effect of automatic temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described with embodiment below in conjunction with accompanying drawing.

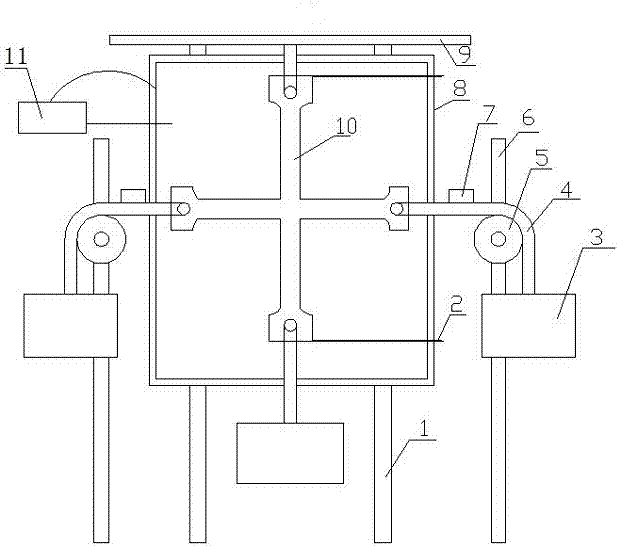

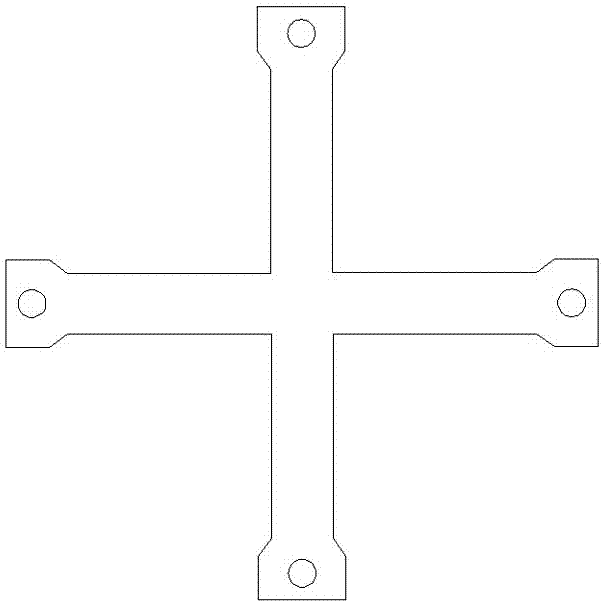

[0019] Such as figure 1 , 2 As shown, a two-way stress high-temperature creep test device includes a sample 10 and a high-temperature furnace 8, and is characterized in that: vertical narrow slots are symmetrically opened on the two side walls of the high-temperature furnace, and the sample is Cross-shaped, the upper end of the vertical bar is fixed on the top in the high-temperature furnace, and the lower end is hung with a weight 3, and the left and right ends of the horizontal bar are respectively connected to one end of a steel rope 4, and the other end of the steel rope passes through the long hole 1. After bypassing a pulley 5, a weight is hung. The pulley is arranged on a vertical guide rod and can move vertically along the guide rod 6. The bottom of the high-temperature furnace is provided with a bottom hole, and the lower end of the sample is hung....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com