Continuous production complete equipment for buckwheat bowl holder

A complete set of equipment, buckwheat bowl holder technology, applied in food preparation, food forming, food science and other directions, can solve problems such as low work efficiency and short shelf life, improve sealing effect, improve storage quality, and achieve continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

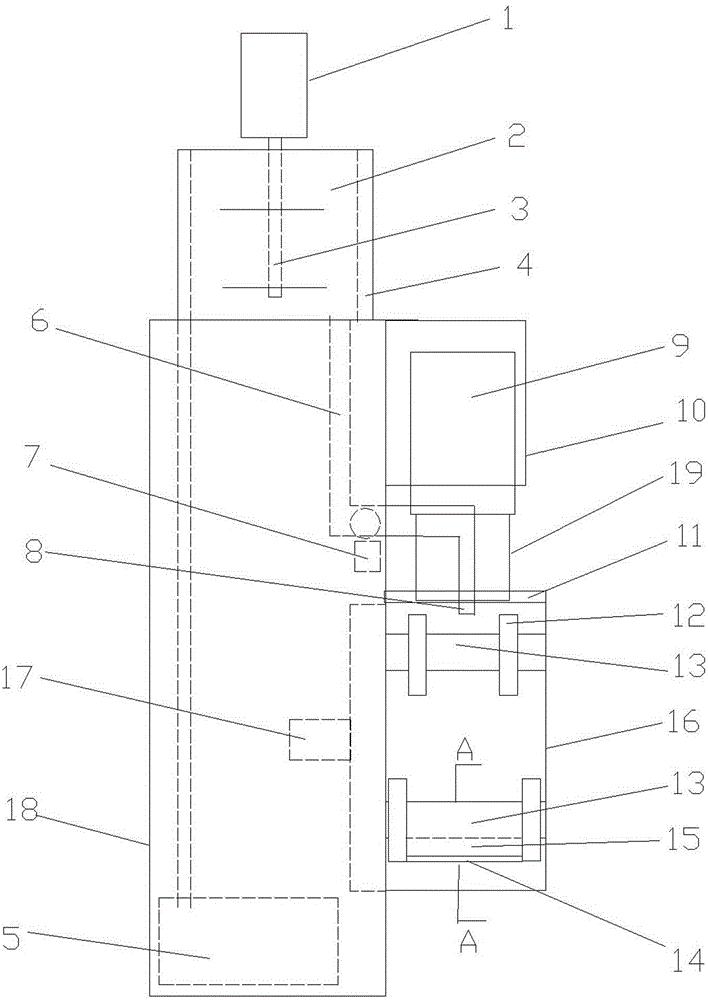

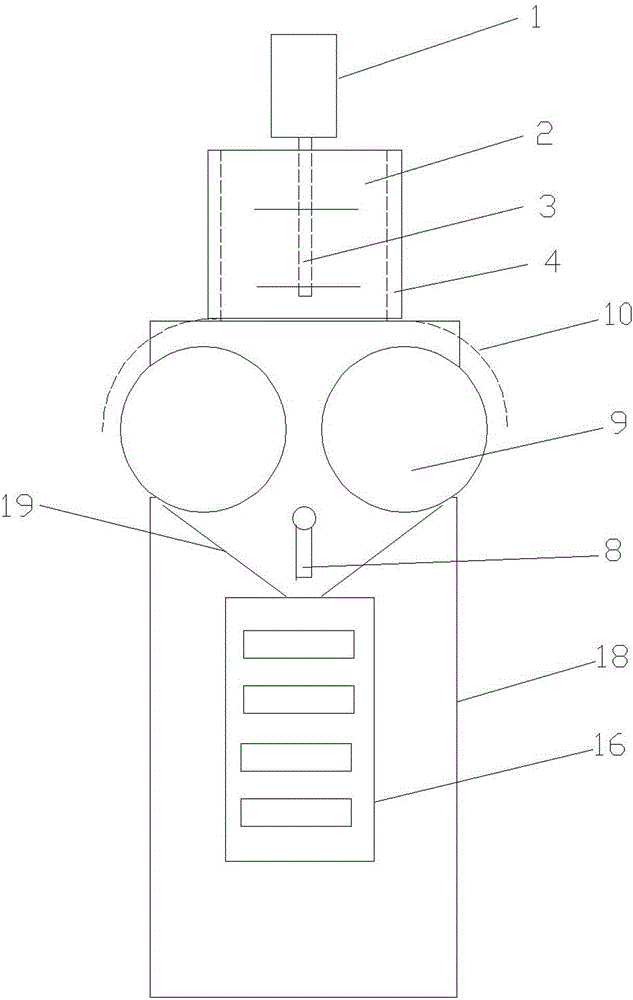

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

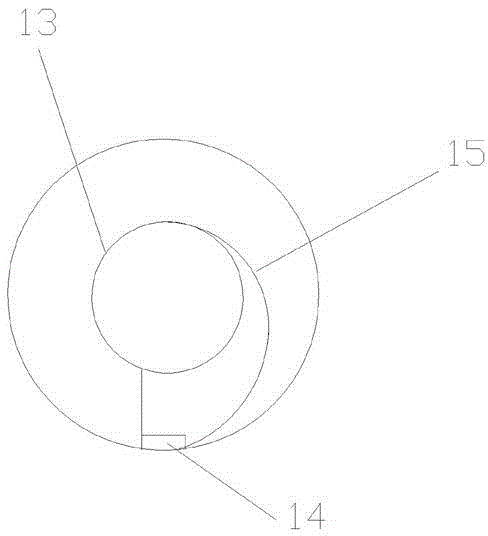

[0026] Such as figure 1 , 2As shown, the batter filling machine of the buckwheat noodle bowl holder continuous production complete set of equipment of the present invention includes a motor 1, a hopper 2, an agitator 3, a heat transfer oil interlayer 4, a heat transfer oil heating and control device 5, a discharge pipe 6, and a discharge pipe 6. Control device 7, discharge port 8, packaging film roller 9, protective cover 10, packaging film guide roller 11, longitudinal side heat sealing roller 12, heat sealing roller heater insulation cover 13, transverse side heat sealing roller bar 14, belt Material exhaust roller surface 15, heat dissipation protective cover 16, heat-sealing series motor and control device 17, frame 18. The hopper 2 is arranged on the frame 18, and the periphery of the hopper 2 is a heat transfer oil interlayer 4, and the heat transfer oil interl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com