A fast and intelligent detection device and method for optical lens defective products

An optical lens, intelligent detection technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of complex instrument structure, inability to batch processing, slow detection speed, etc., to achieve the effect of simple operation, accurate and reliable results, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

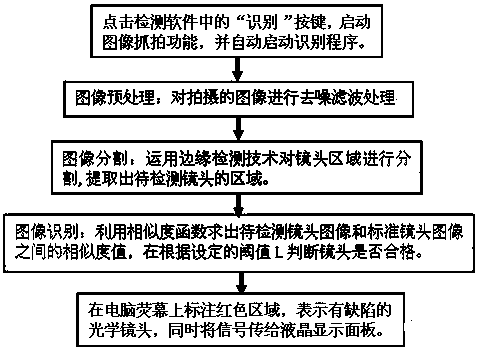

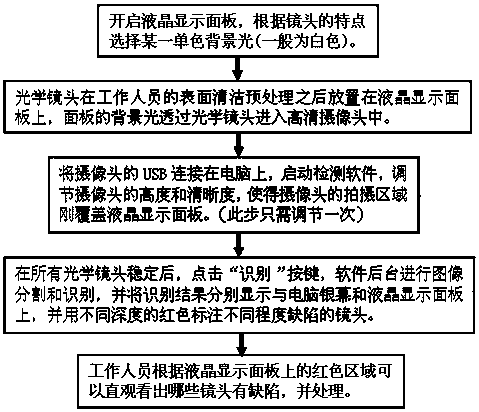

[0038] In order to overcome the shortcomings of manual detection and conventional optical lens detection methods, the present invention uses image segmentation and pattern recognition methods for automatic batch detection. The following describes in detail in conjunction with the accompanying drawings and specific implementation methods.

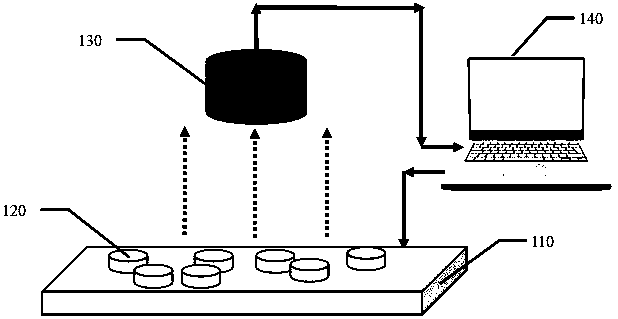

[0039] The rapid intelligent detection device for optical lens defective products of the present invention includes a (high-definition digital) camera 130, an image analysis unit 140 and a liquid crystal display panel 110 connected in sequence, such as figure 1 shown.

[0040] A liquid crystal display panel, the liquid crystal display panel is composed of a high-resolution liquid crystal display, and is used to place the lens 120 to be tested, and provide background light for imaging, and at the same time carry out color identification for the areas where different lenses are located according to the detection results. Therefore, the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com