Low frequency surface plasmon waveguide structure

A surface plasmon and waveguide structure technology, applied in waveguides, waveguide-type devices, circuits, etc., can solve problems such as poor constraints, inability to effectively concentrate electromagnetic waves, and inability to achieve better distribution of electromagnetic fields, and the distribution of electromagnetic fields is easy to control. , the effect of effective constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific technology adopted in the present invention will be further described through the following examples and attached drawings.

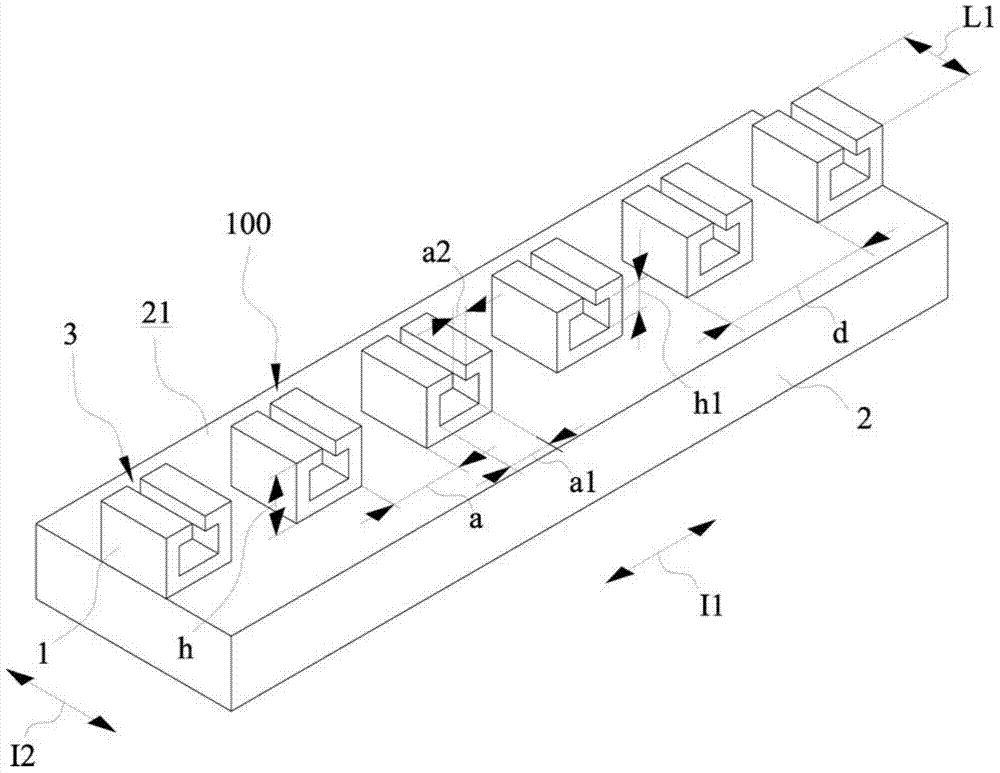

[0055] see figure 1 , which shows a perspective view of the low-frequency surface plasmon waveguide structure of the first embodiment of the present invention. The low-frequency surface plasmon waveguide structure of the present invention includes a plurality of unit cell blocks 1 arranged at a predetermined distance from each other on the upper surface 21 of a flat metal substrate 2 . Each unit cell block 1 is arranged in a straight line on the upper surface 21 of the metal substrate 2 along the one-dimensional arrangement direction I1 at a subwavelength period (subwave length periodic) to form a hollow metal block periodic structure 100 (metallic hollow blocks periodic structure ).

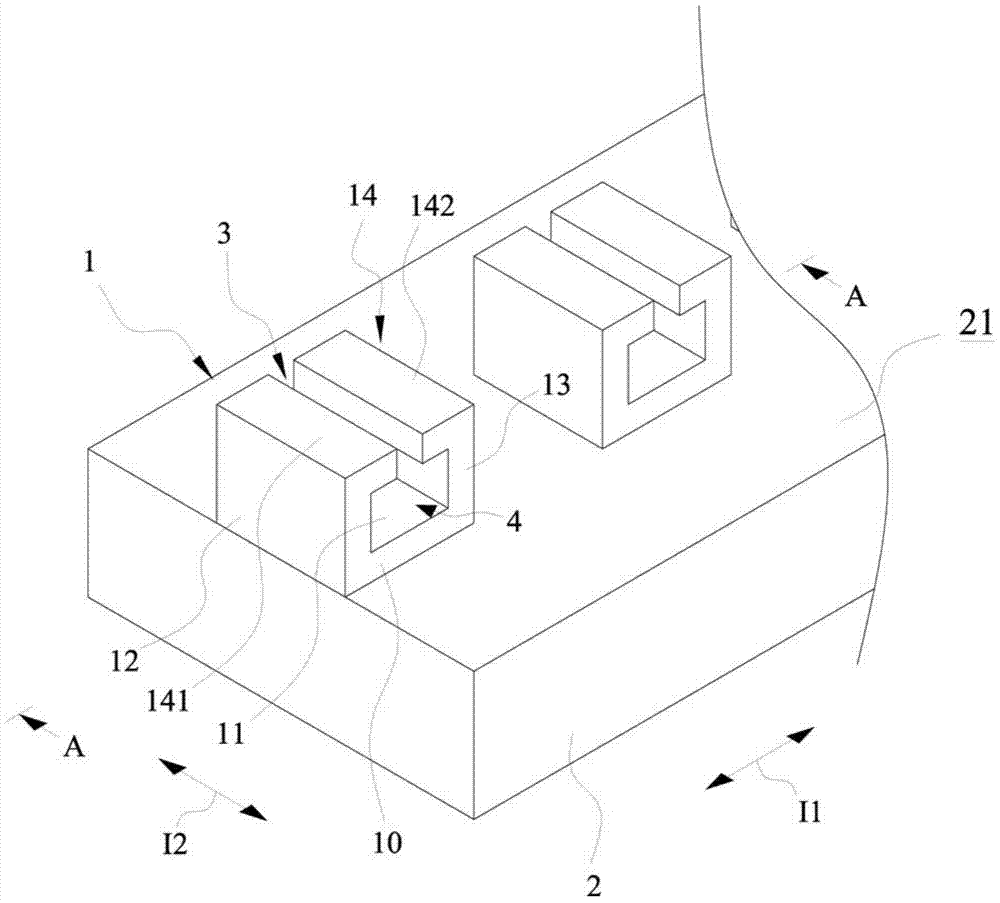

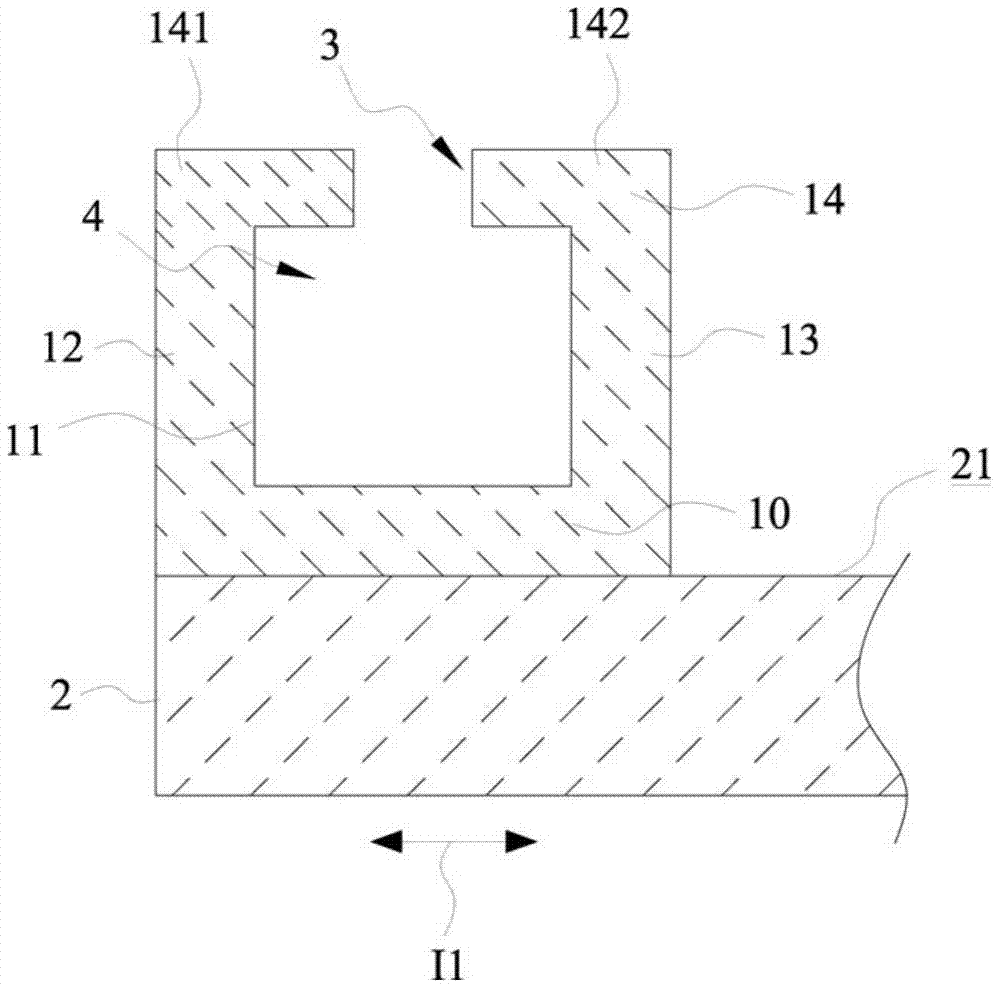

[0056] refer to Figure 2-Figure 3 , are respectively an enlarged perspective view and a cross-sectional view of the specific embodiment of the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com