Permanent magnet synchronous motor starting mechanism

A technology of permanent magnet synchronous motor and starting mechanism, which is applied to electric components, electrical components, electromechanical devices, etc., can solve problems such as increasing structural complexity, and achieve the effects of simple structure, large rotation angle and high starting success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

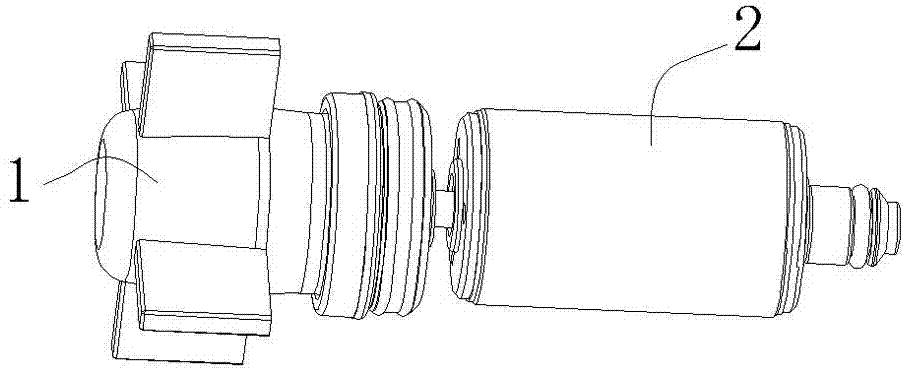

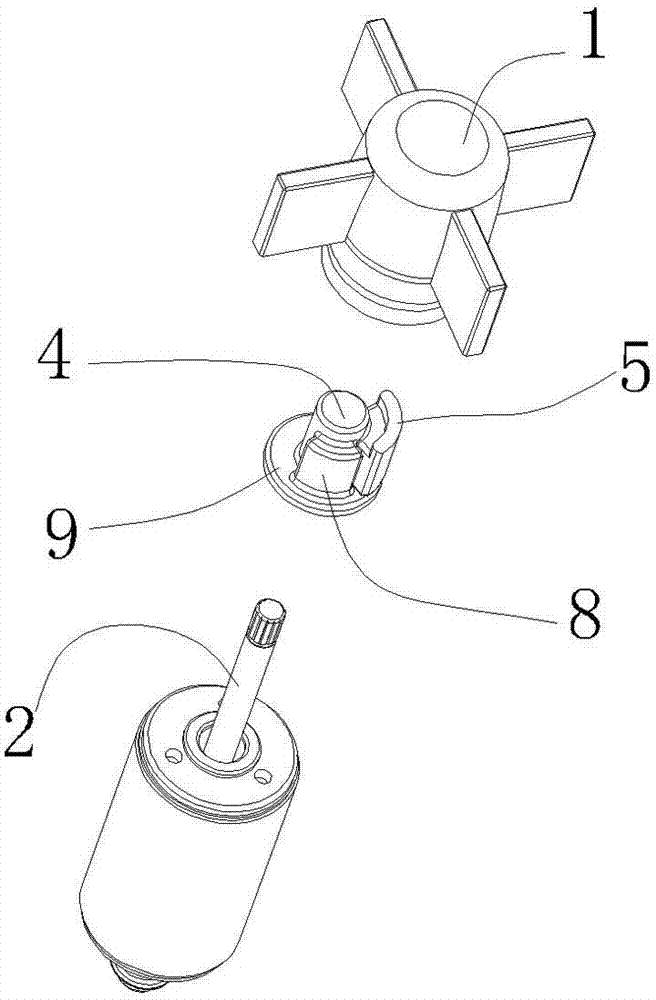

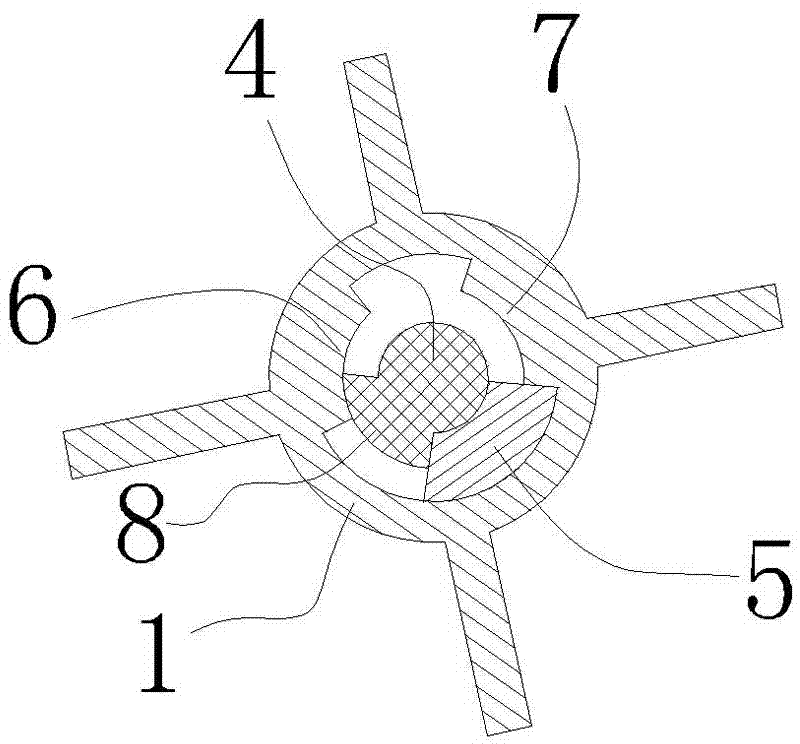

[0022] refer to Figure 1~Figure 4 , permanent magnet synchronous motor starting mechanism, including impeller 1, rotor 2, described impeller 1 has a mounting chamber 3, a driving sleeve 4 is arranged in the described mounting chamber 3, described rotor 2 and described driving sleeve 4 connected, so that the rotor 2 can drive the drive sleeve 4 to rotate. In this embodiment, the rotor 2 is inserted from the tail of the driving sleeve 4 and rigidly connected with the driving sleeve 4 as a whole.

[0023] There is a buffer member 5 between the drive sleeve 4 and the inner wall of the installation cavity 3, and the buffer member 5 interferes with the drive sleeve 4 in the radial direction, and the buffer member 5 and the The inner side walls of the installation cavity 3 interfere with each other in the radial direction, so that the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com