Tractor operating depth resistance-position adjusting electric control device and method

An electric control device, tractor technology, applied in the direction of adjustment device, lifting device of agricultural machinery, agriculture, etc., to achieve the effect of convenient installation and setting of the device, convenient setting and adjustment, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

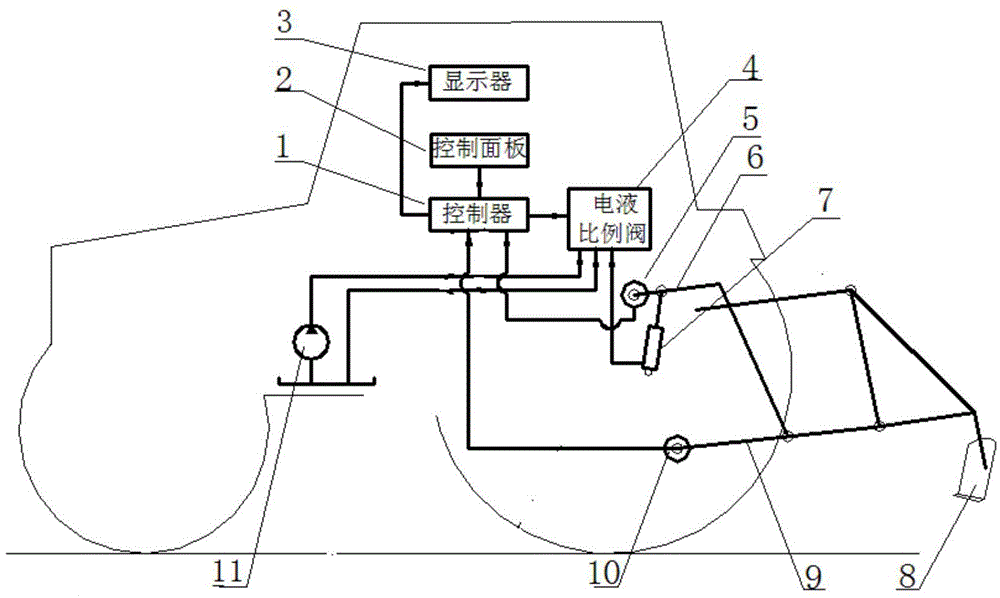

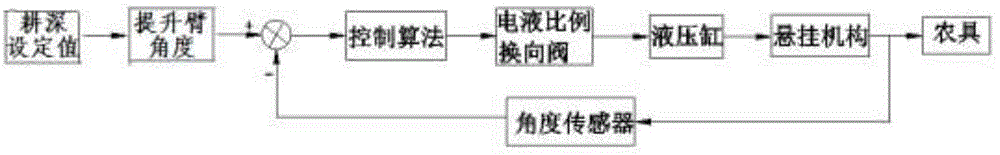

[0030] The electronic control device consists of a controller, an electro-hydraulic proportional reversing valve, a display, a control panel, an angle sensor and a pin-type force sensor, and replaces the hydraulic control valve and the mechanical traction resistance signal and implement position in the traditional tractor hydraulic suspension system. Signal detection and transmission mechanism. The structure of the whole device is as figure 1 As shown, an angle sensor 5 is installed at the rotating shaft of the lifting arm 6 of the suspension device to detect the rotation angle of the lifting arm 6; the pin type traction force sensor 10 is installed in the hinged hole of the lower rod 9 and the tractor body to realize the connection between the lower rod and the tractor body. The articulated connection of the tractor body is used to detect the pulling force of the lower rod, that is, the traction force.

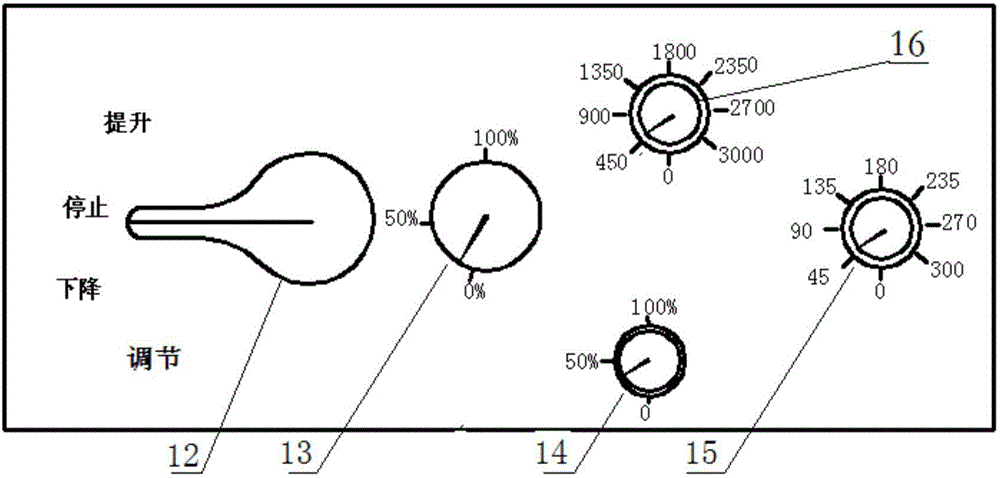

[0031] Control panel 2 setting mode knob 12, agricultural tool lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com