Rapid sterilization method and device

A technology of disinfection device and disinfection method, which is applied in the direction of disinfection, water supply equipment, sanitary equipment for toilets, etc., can solve the problems of inability to achieve rapid and thorough disinfection, limited area, etc., and achieve improved ultraviolet conversion efficiency, rapid disinfection, and improved disinfection effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0074] The high-purity alumina refers to an alumina material with an aluminum oxide content greater than 98%, which can be selected from any of the following embodiments: the high-purity alumina has an aluminum oxide content ≥ 98.5%, and the above-mentioned high-altitude aluminum oxide with a thickness of 1 mm The ultraviolet transmittance of pure alumina is ≥ 86%; the content of aluminum oxide in high-purity alumina is ≥ 99%, and the ultraviolet transmittance of the above-mentioned high-purity alumina with a thickness of 1mm is ≥ 88%; the trioxide content of high-purity alumina The content of di-aluminum is ≥99.9%, and the ultraviolet transmittance of the above-mentioned high-purity alumina with a thickness of 1mm is ≥92%.

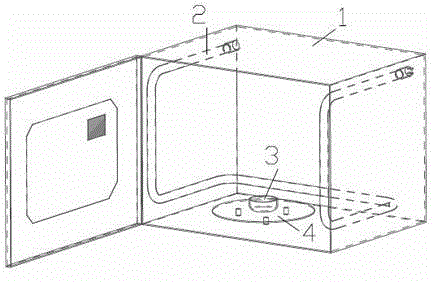

[0075] Correspondingly, the present invention also provides a rapid disinfection device, including a disinfection chamber 1, an ultraviolet light source 2 and a support mechanism 4 are arranged in the disinfection chamber 1, and the support mechanism 4 is ...

Embodiment 1

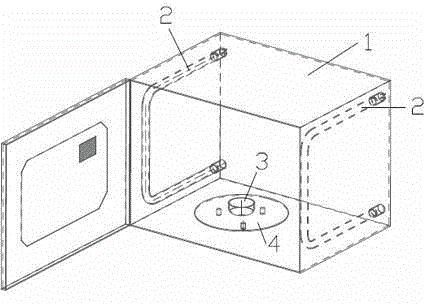

[0098] see figure 1 , the sterilizer includes a disinfection chamber 1, an ultraviolet light source 2, containers 3 and / or articles to be sterilized, and a support mechanism 4, and the containers 3 and / or articles to be sterilized are placed on the support mechanism 4 of the disinfection chamber 1, and the ultraviolet light source 2 Set as a U-shaped ultraviolet lamp, the U-shaped ultraviolet lamp is rotated 90° and installed on opposite sides of the disinfection chamber 1, and the ultraviolet radiation power per unit area of the ultraviolet light source is 20mW / cm 2 , the UV conversion efficiency of the UV light source is 30%, and the tube current density of the UV lamp is 0.3 A / cm 2 ; The container 3 to be sterilized is made of quartz glass with a silicon dioxide content greater than 99.5%, and the ultraviolet transmittance of the above-mentioned quartz glass with a thickness of 1mm is ≥88%.

Embodiment 2

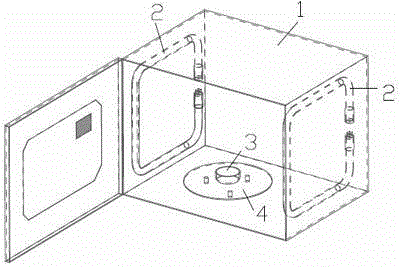

[0100] see figure 2 , the sterilizer includes a disinfection chamber 1, an ultraviolet light source 2, containers 3 and / or articles to be sterilized, and a support mechanism 4, and the containers 3 and / or articles to be sterilized are placed on the support mechanism 4 of the disinfection chamber 1, and the ultraviolet light source 2 Set as a □-shaped ultraviolet lamp, the □-shaped ultraviolet lamp is installed on the opposite sides of the disinfection chamber 1, and the bottom of the ultraviolet light source 2 is lower than the support mechanism 4, and the ultraviolet radiation power per unit area of the ultraviolet light source is 25mW / cm 2 , the UV conversion efficiency of the UV light source is 35%, and the tube current density of the UV lamp is 0.4 A / cm 2 ; The container 3 to be sterilized is made of high boron glass with a silicon dioxide content of ≥60% and a boron oxide content of ≥10%. The ultraviolet transmittance of the above-mentioned high boron glass with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com