Method for manufacturing steel channel for ventilation of motor

A processing method and technology of ventilated channel steel, applied in the field of channel steel processing, can solve the problems of difficulty in pass adjustment, difficulty in pass design of two-roll mills, difficulty in biting, etc., and achieve difficulty in pass adjustment and pass The design is difficult and the pass design is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

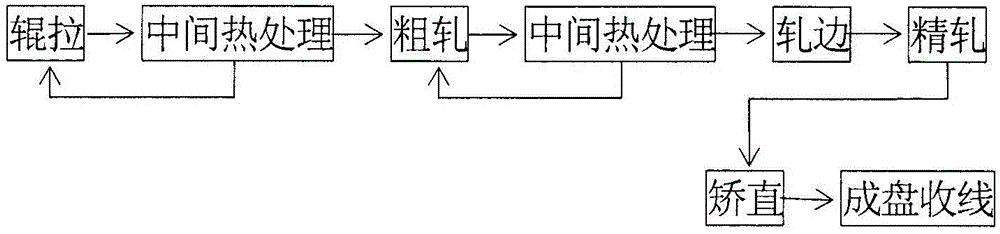

[0033] The present embodiment is a processing method of using carbon steel Q235 and adopting a roll drawing-cold rolling process to process a channel steel for motor ventilation with a size of 6.0-0.06mm×5.0±0.05mm. The method includes:

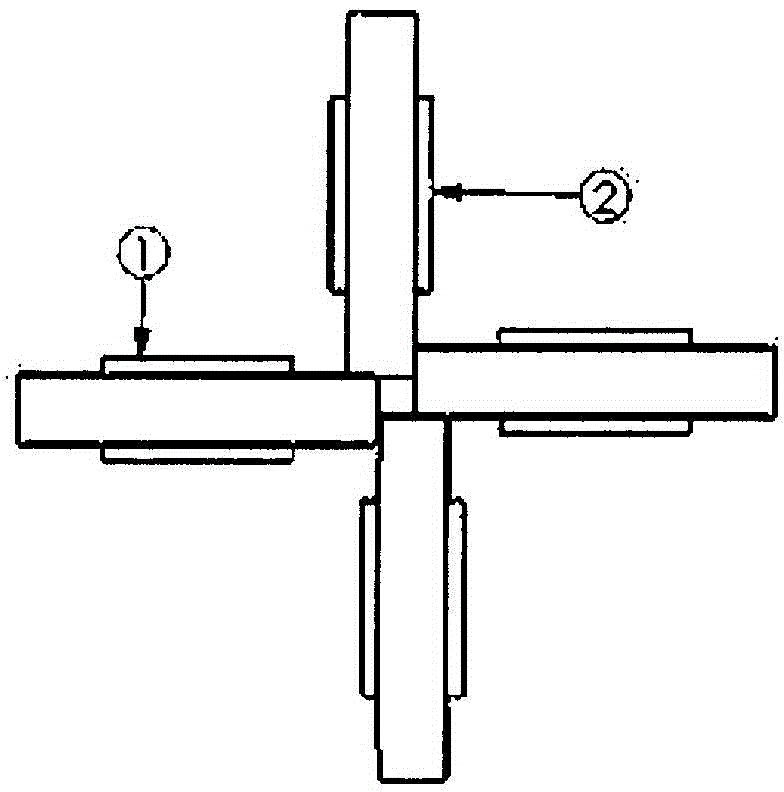

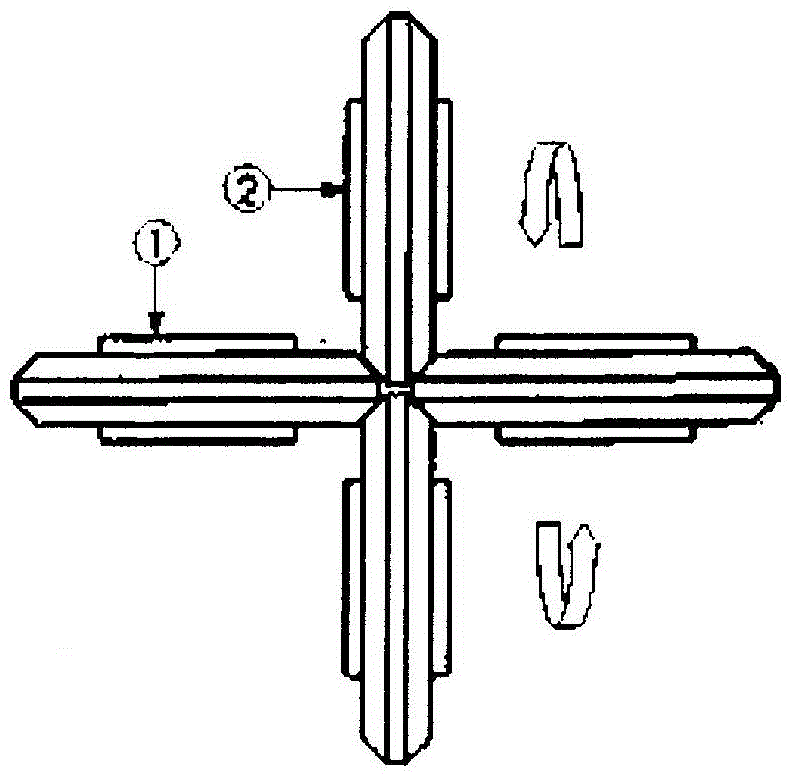

[0034](1) Drawing: Four-pass drawing is carried out by using a four-roller drawing die to obtain a billet whose cross-sectional shape is close to the cross-sectional shape of the ventilation channel steel. The four-roller drawing die is a known technology. The four-roller drawing die involved in this step is designed and manufactured according to known principles and the requirements of producing ventilated channel steel. It consists of a pair of horizontal rolls and a pair of vertical rolls (vertical rolls Or horizontal roll is determined by whether the roll surface is vertical or horizontal). The size of the roller is φ140mm×φ54mm×35mm, the material is Cr12MoV, HRc60-62 after quenching and tempering heat treatment. The four rollers are sta...

Embodiment 2

[0060] This embodiment is a processing method for using stainless steel 1Cr18Ni9Ti, adopting a roll drawing-cold rolling process to process 6.0-0.06mm × 5.0 ± 0.05mm channel steel for motor ventilation, and the method includes:

[0061] (1) Rectangular drawing: Four-roller drawing die is used for two-pass drawing, and the round wire is drawn into a rectangle, which is convenient for the subsequent roller drawing. The four-roller drawing die is a known technology. The four-roller drawing die involved in this step is designed and manufactured according to known principles and the requirements of producing ventilated channel steel. It consists of a pair of horizontal rolls and a pair of vertical rolls (vertical rolls Or horizontal roller is determined by whether the roller surface is vertical or horizontal), the size of the roller is φ140mm×φ54mm×35mm, the material is Cr12MoV, HRc60-62 after quenching and tempering heat treatment. The four rollers are stacked on each other, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com