Main shaft structure of numerically-controlled machine tool

A technology of CNC machine tools and spindles, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as difficult processing and unsatisfactory users, and improve rigidity, surface hardness and peeling resistance. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

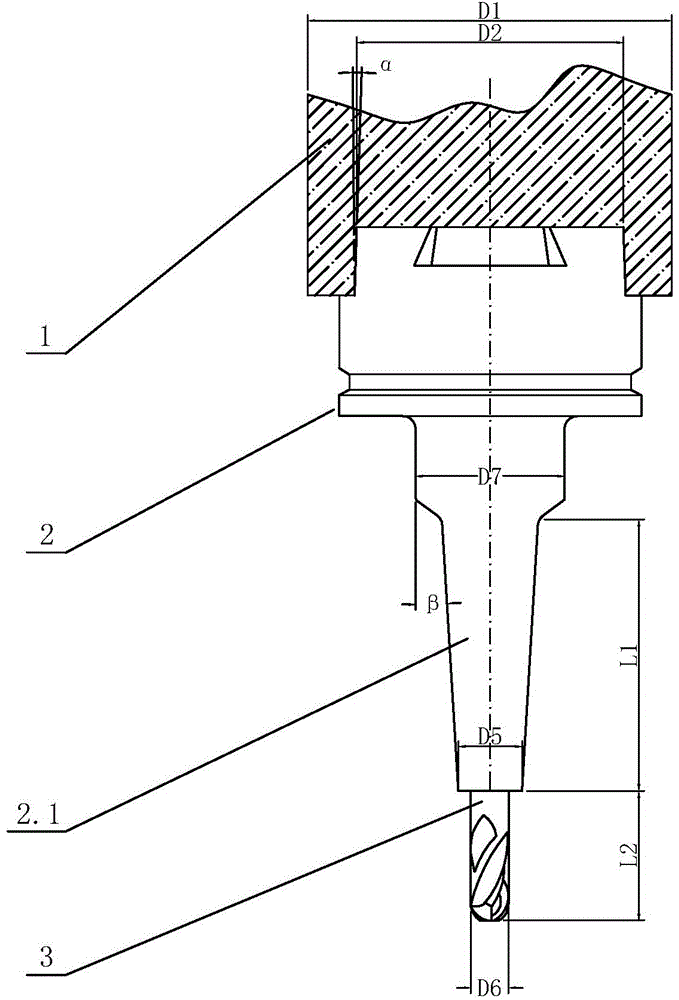

[0020] see figure 1 , the main shaft structure of this CNC machine tool includes a tool bar 2 connected to the main shaft 1, a cutter head 3 connected to the tool bar 2, the head of the tool bar 2 is inserted in the main shaft 1, and the tail 2.1 of the tool bar 2 is in the shape of Inverted cone shape, the tail 2.1 is in contact with the cutter head 3, and the ratio of the end diameter D5 of the tail 2.1 to the diameter D6 of the cutter head 3 is less than or equal to 1.7:1.

[0021] In this embodiment, the ratio of the diameter D1 of the end of the spindle 1 to the diameter D2 of the head of the tool holder 2 is less than or equal to 1.5:1.

[0022] The taper α of the head of the cutter bar 2 is less than or equal to 2 degrees.

[0023] The taper β of the tail portion 2.1 of the cutter bar 2 is less than or equal to 10 degrees and greater than or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com