On-line prediction method and device for welding seam wear amount of laser forging composite arc welding

An arc welding and prediction method technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of inability to precisely control the amount of wear, inability to guarantee the wear resistance of parts welds, and predict the amount of weld wear, etc. The effect of eliminating internal defects, reducing weld forming defects, and reducing welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

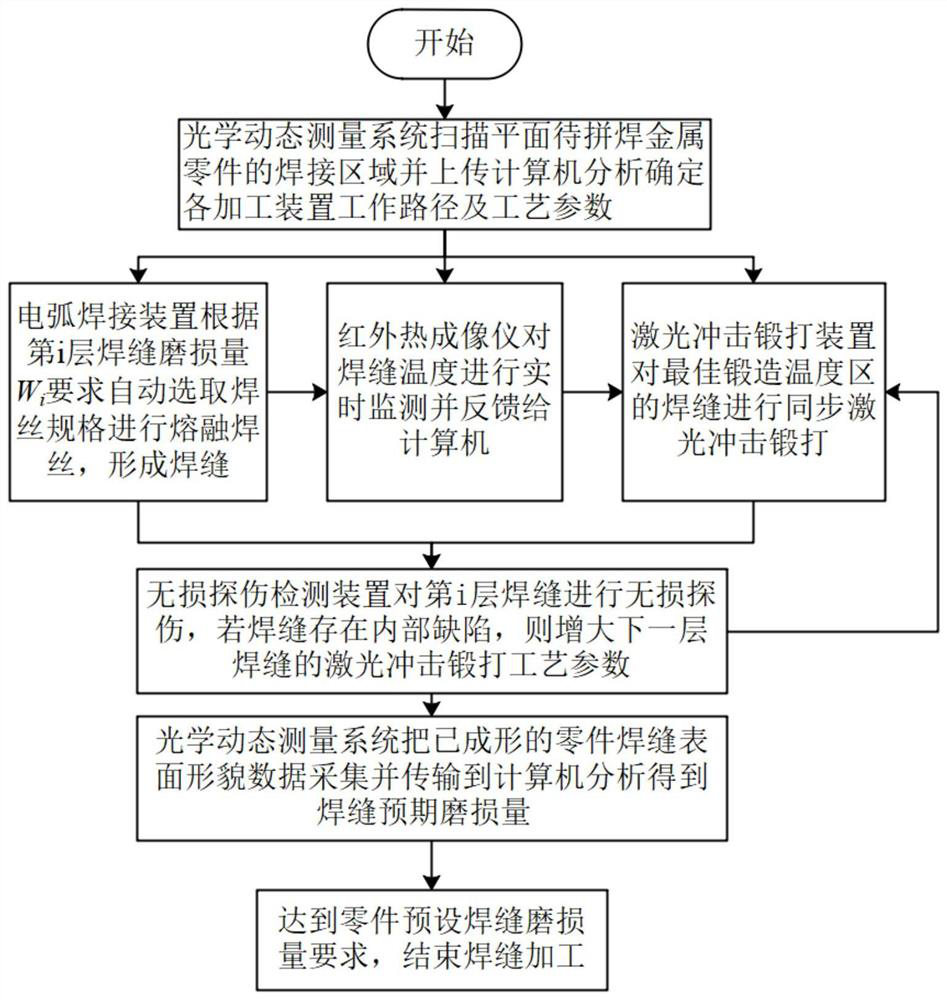

[0050] The on-line prediction method of the laser forging composite arc welding seam wear amount in this embodiment is applied to the laser forging composite arc welding of the metal plane welding seam, refer to the appendix figure 1 , the method includes the following steps:

[0051] Step S100: Scan the welding area of the plane metal parts to be tailored by an optical dynamic measurement system and upload the computer to analyze the shape and size of the plane welding area, and obtain the arc welding path and the laser shock forging path through computer planning;

[0052] Step S200: setting arc welding process parameters and laser shock forging process parameters of the next layer of welds;

[0053] Step S300: start the arc welding device, start wire feeding according to the set arc welding path and process parameters, and the arc heat melts the welding wire in the welding area to form the first layer of welds or the i+1th layer of welds;

[0054]Step S400: While forming...

Embodiment 2

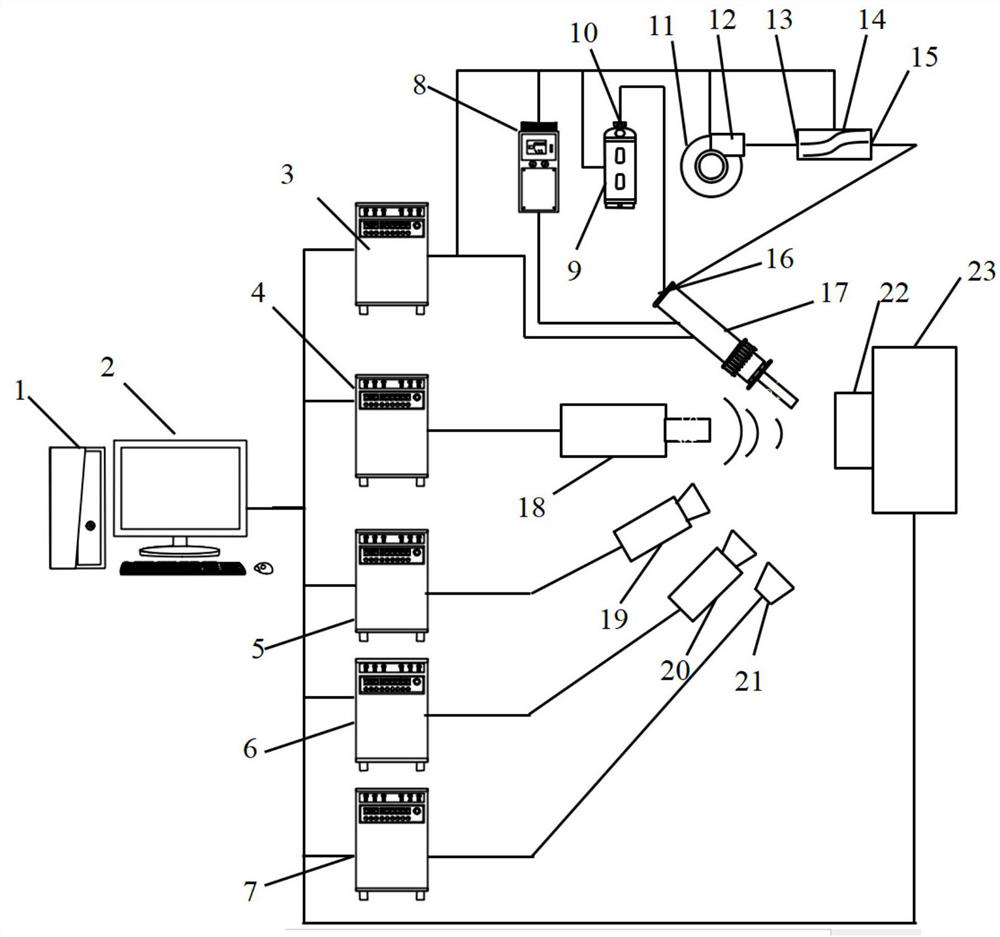

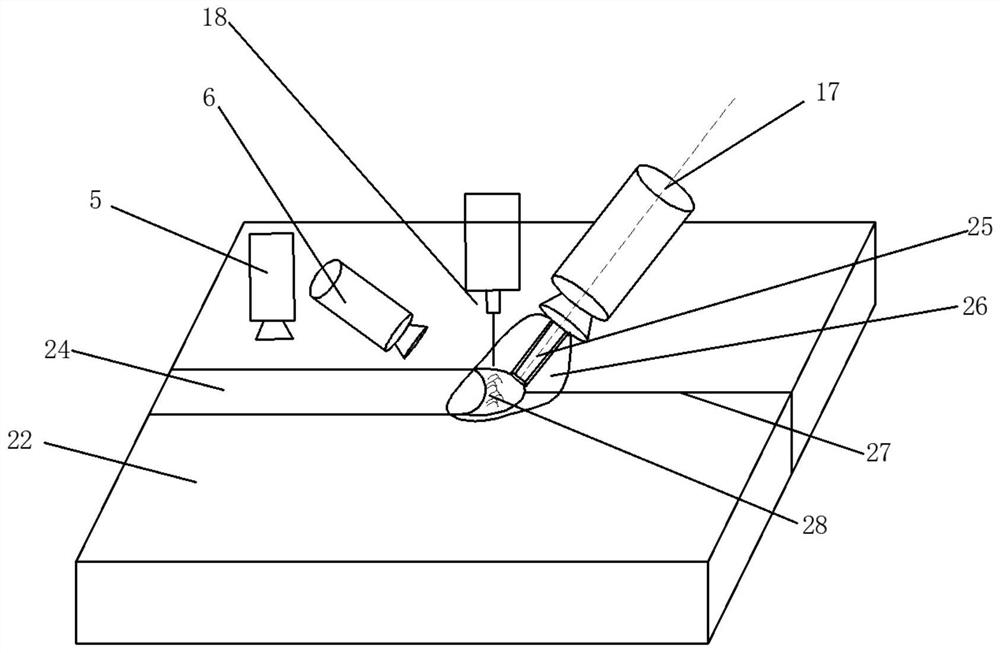

[0084] An online prediction device for laser forging composite arc welding seam wear amount using the online prediction method of laser forging composite arc welding seam wear amount, refer to appendix figure 2 and 3 , including a computer 1, a display screen 2, a workbench 23 and an infrared thermal imager 6 above the workbench 23, an arc welding device 3, a laser impact forging device 5, and an optical dynamic measurement system;

[0085] The worktable 23 is used to place the parts to be welded;

[0086] The infrared thermal imager 6 is used to monitor the temperature of the welding seam 24 in real time;

[0087] The arc welding device 3 is used to control the movement of the arc welding gun and melt the welding wire 25 to form a weld on the part, and the angle between the center line of the arc welding gun nozzle and the worktable 23 is 35° to 50°;

[0088] The laser impact forging device 5 performs laser impact forging on the weld 24 through the forging laser beam 28, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com