A double turntable mechanism

A turntable mechanism and double turntable technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of slow speed, low work efficiency, and easy fatigue of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

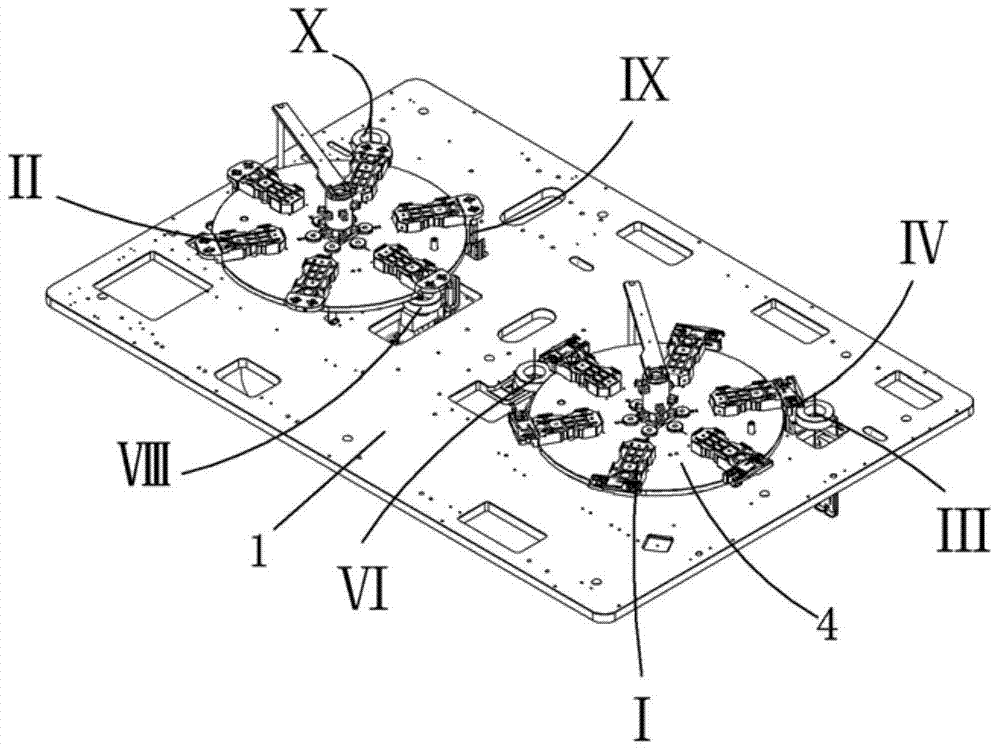

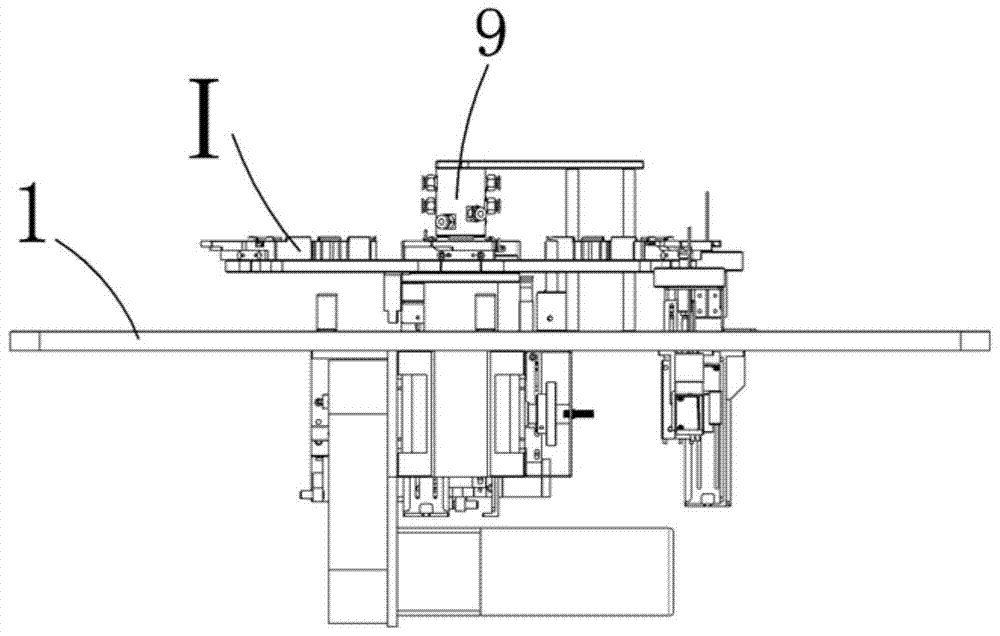

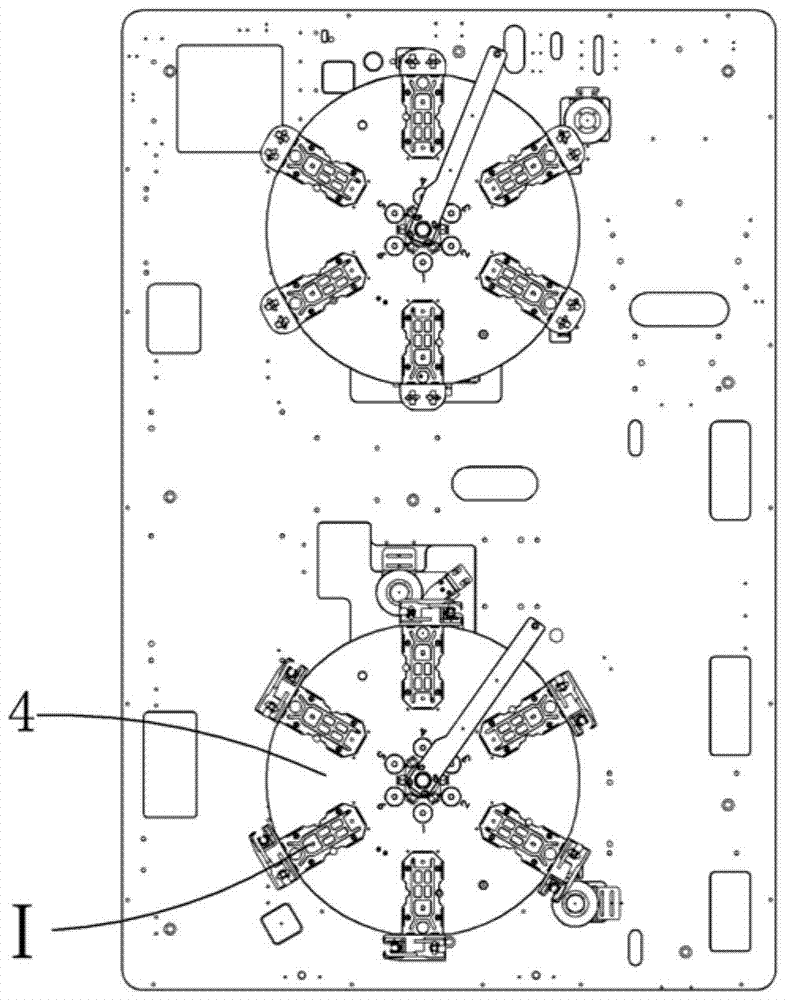

[0045] Examples, see attached Figure 1-12 , a double turntable mechanism, which includes a bottom plate 1, on which a turntable mechanism a and a turntable mechanism b are installed, and six groups of product carriers aI are uniformly installed on the turntable mechanism a; on the turntable mechanism a, evenly installed There are six groups of product carriers bⅡ;

[0046] The turntable mechanism a and the turntable mechanism b have the same structure, and the turntable mechanism a includes a sextant a2, a rotating shaft a3, a turntable a4, a rotating photoelectric sensor a5, a rotating optical fiber sensor a6, a rotating optical fiber sensor fixing frame a7, a rotating sensor slice a8, four-way rotary joint a9, bridge connecting plate a10 and support column a11, the sextant a is installed at the bottom of the bottom plate, and the turntable a is installed on the output end of the sextant a through the rotating shaft a to realize indexing intermittent rotation, And the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com