A Simple Fixture for Machining Parallel Groove of Slider

A technology of tooling fixtures and parallel grooves, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as inability to guarantee processing dimensional stability, affect processing accuracy, correct operation waste force, etc., and achieve shortening auxiliary Man-hours, simplification of operations, and weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

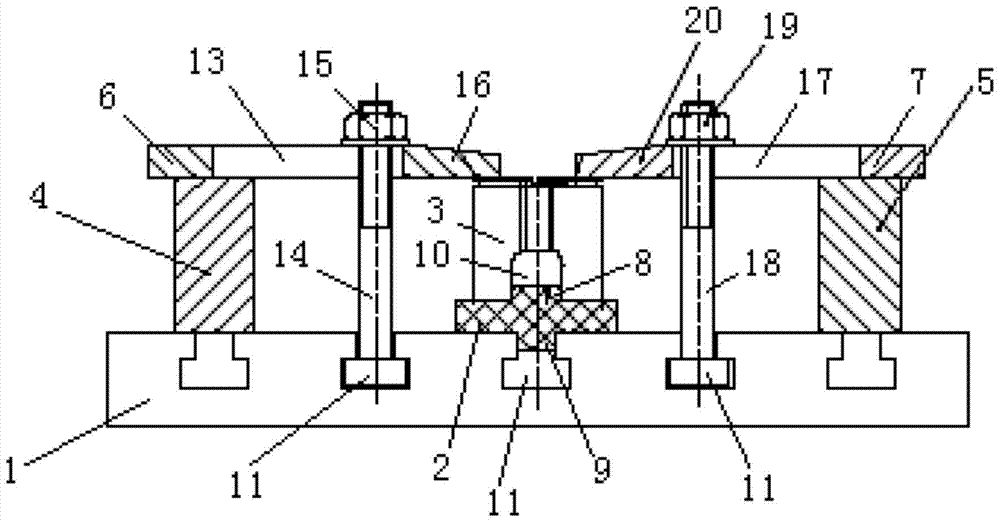

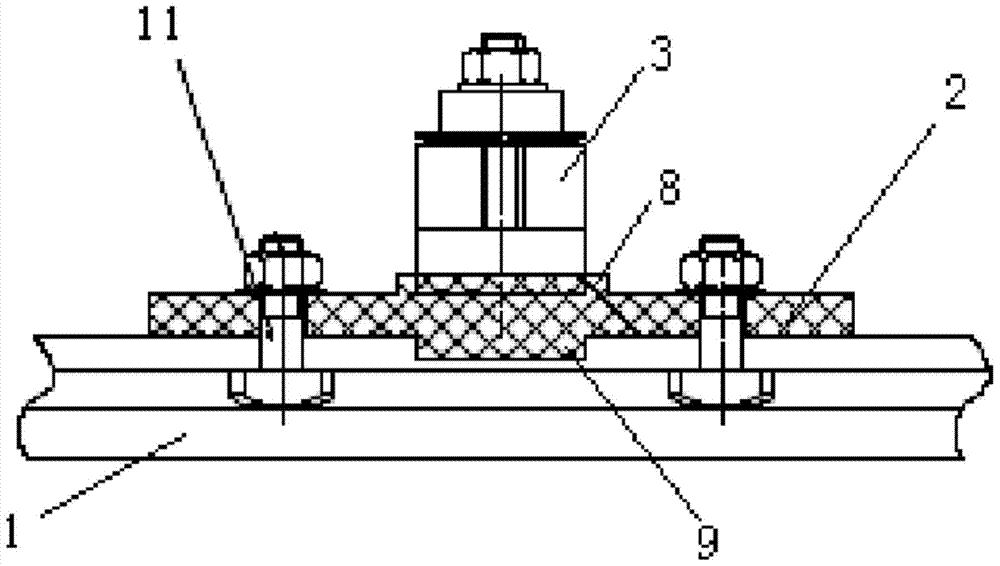

[0025] Such as Figure 1-2 As shown, a simple tooling fixture for machining parallel grooves of sliders, the fixture includes a convex positioning block 2 arranged on a machine tool 1, a slider 3 to be processed arranged on the convex positioning block 2, symmetrically arranged on The first machine block 4 and the second machine block 5 on the left and right sides of the convex positioning block 2 are respectively arranged on the first machine block 4 and the second machine block 5 and are used for pressing The first press plate 6 and the second press plate 7 of the slide block 3 to be processed, the convex positioning block 2 are fixedly connected with the machine tool 1 along the feed direction of the machine tool 1, the first press plate 6 and the second press plate 7 are arranged oppositely, and the slide to be processed Block 3 is compressed and fixed on the convex positioning block 2.

[0026] Wherein, the upper and lower surfaces of the convex positioning block 2 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com