Flexible clamping claw

A flexible clamping and claw technology, applied in the field of agricultural and forestry equipment, can solve the problems of difficulty in implementation and easy winding, etc., and achieve the effects of guaranteed success rate, convenient operation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

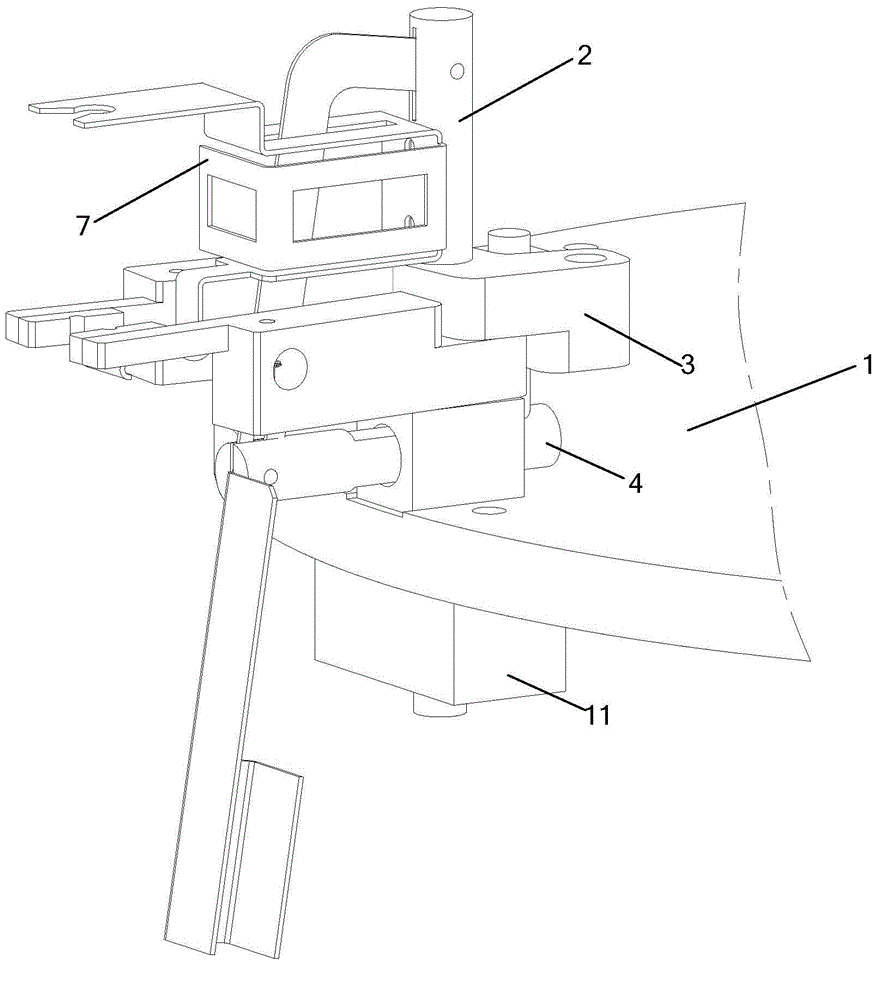

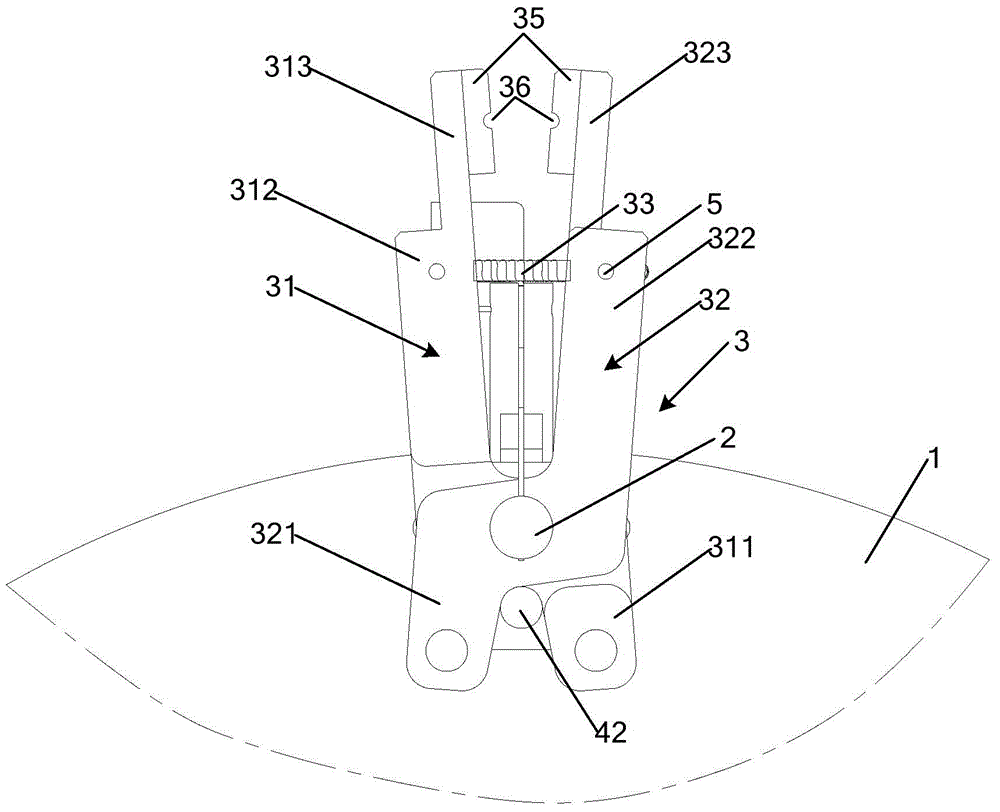

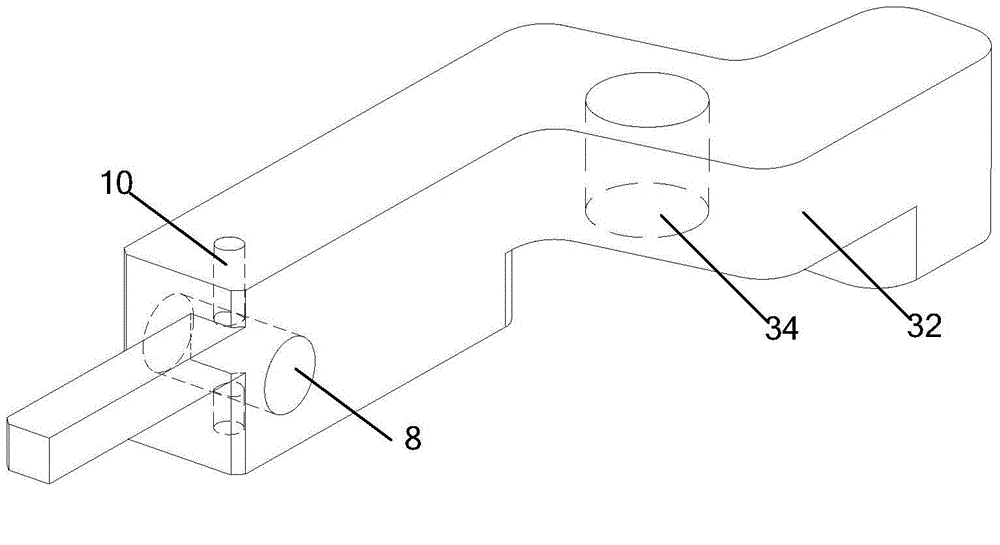

[0020] figure 1 It is a schematic structural diagram of the flexible clamping gripper provided by Embodiment 1 of the present invention, Figure 2a It is a schematic structural diagram of a clamping device for a flexible clamping gripper provided in Embodiment 1 of the present invention, Figure 2b Another structural schematic diagram of the clamping device for the flexible clamping gripper provided by Embodiment 1 of the present invention, image 3 Schematic diagram of the structure of the pushing device for the flexible clamping claw provided in Embodiment 1 of the present invention; Figure 1~3 As shown, the flexible clamping gripper provided by this embodiment includes: a base 1, a fixed shaft 2 vertically and fixedly installed through the base 1, and also includes: a clamping device 3 sleeved on the fixed shaft 2, and for The pushing device 4 that makes clamping device 3 open and close; Wherein, clamping device 3 comprises: left clip body 31, right clip body 32, extensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com