Explosion-proof component and oil-gas recovery system for oil-gas recovery system

A technology of oil and gas recovery system and components, which is applied in the direction of engine components, containers, functional valve types, etc., can solve the problems of potential safety hazards, oil storage tank combustion, explosion, etc., and achieve the effect of low maintenance cost and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

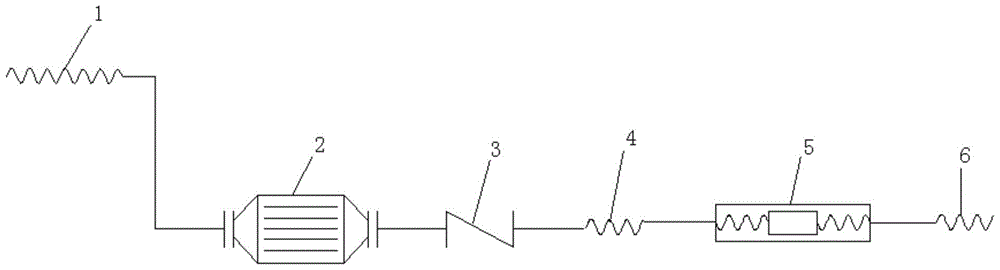

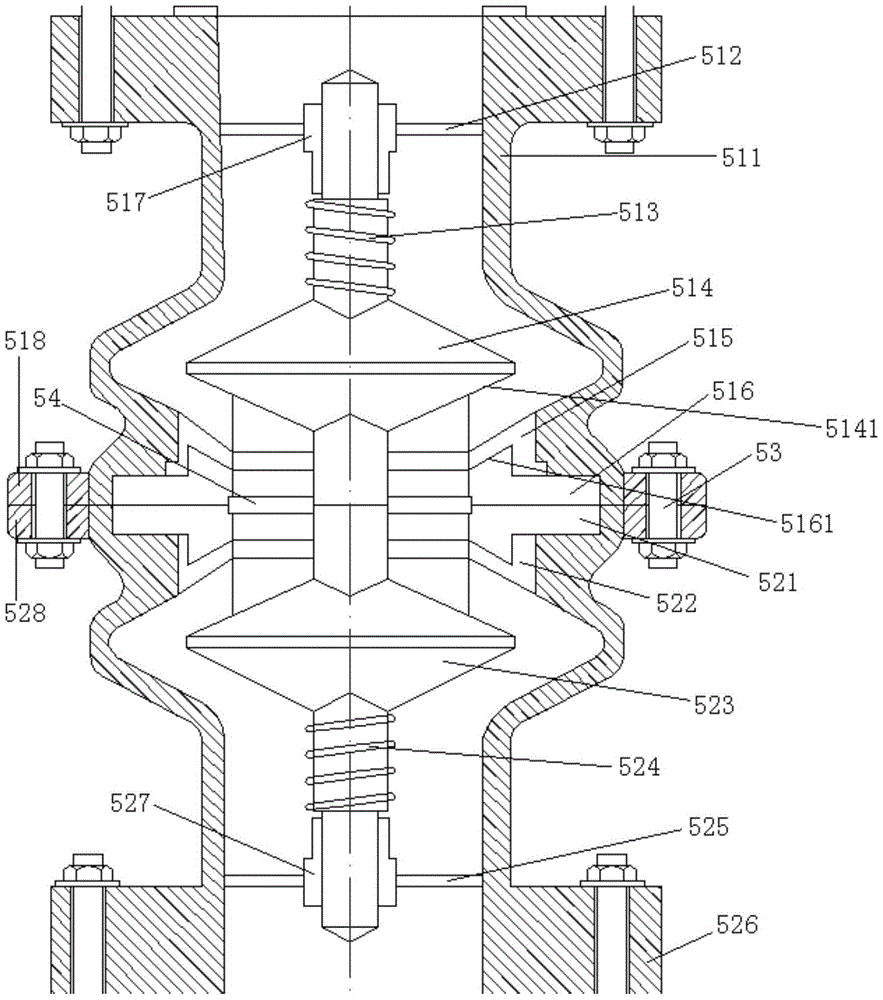

[0030] see figure 1 , a flameproof assembly for oil and gas recovery system, including hose I1, flame arrester 2, check valve 3, hose II4, breakaway valve 5 and hose III6, said hose I1, flame arrester 2, Check valve 3, hose II 4, breakaway valve 5 and hose III 6 are connected in sequence. The flameproof assembly of the present invention is arranged on the oil and gas output pipeline between any two adjacent oil storage tanks. When one of the oil storage tanks explodes due to special circumstances, the flameproof assembly can prevent other adjacent oil storage tanks from Cascading explosions occur in the tanks, thereby improving the safety of the oil vapor recovery system.

[0031] Further, the flame arrester 2 is a detonation-resistant flame arrester. The detonation-resistant flame arrester can be purchased on the market. The anti-detonation flame arrester can block the transmission of ignition energy during explosion.

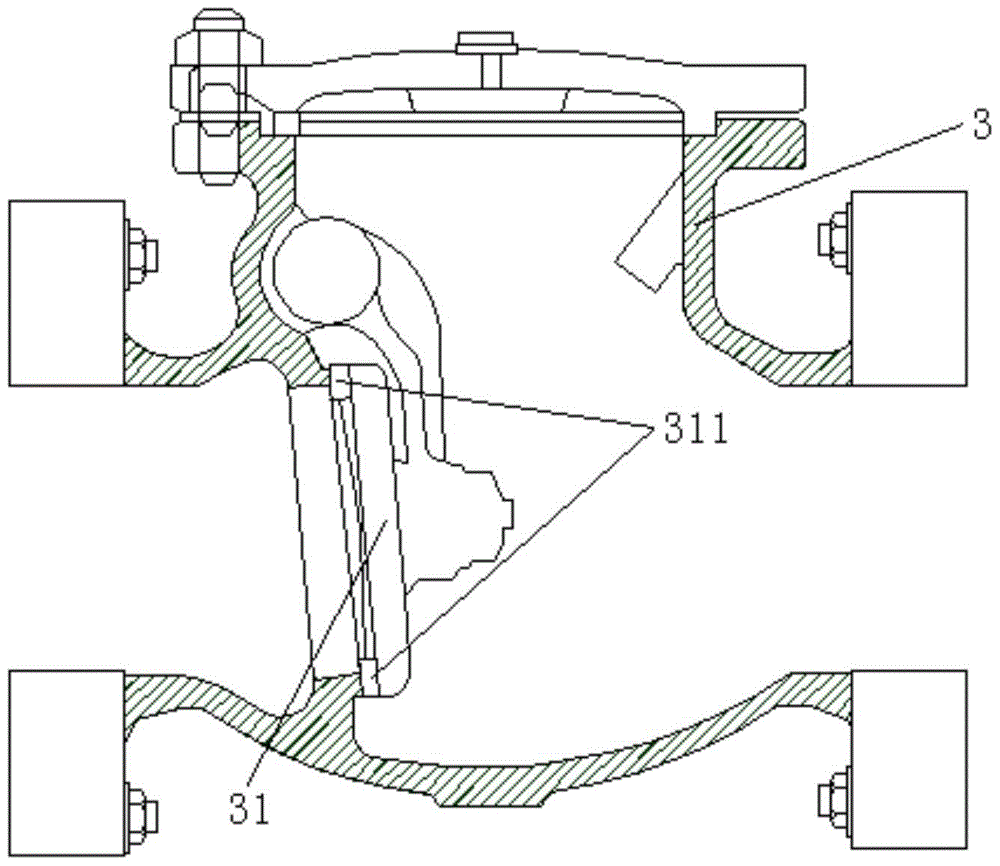

[0032] Further, see figure 2 , the check valve 3 m...

Embodiment 2

[0043] see Figure 5 , the present embodiment discloses an oil and gas recovery system, including several oil storage tanks 7, the explosion-proof assembly for the oil and gas recovery system in Embodiment 1, a flame arrester X9 and an oil and gas recovery device 10, each oil storage tank 7 Each is provided with a breather valve 8, and a three-way valve (not shown in the figure) is arranged between the oil storage tank 7 and the breather valve 8 on it, and each three-way valve is connected with a flameproof assembly, and the flameproof The assembly includes hose I1, flame arrester 2, check valve 3, hose II4, breakaway valve 5 and hose III6, said hose I1, flame arrester 2, check valve 3, hose II4, breakaway valve 5 and the hose III6 are connected in sequence, the hose I1 is connected to the three-way valve, each hose III5 is connected to the flame arrester X9, and the flame arrester X9 is connected to the oil vapor recovery device 10. A valve can be set between the flame arres...

Embodiment 3

[0047] This embodiment discloses an oil and gas recovery system, and the oil and gas recovery system includes the flameproof assembly used in the oil and gas recovery system in Embodiment 1.

[0048] The working process of the flameproof assembly is described below.

[0049] Assuming that the oil and gas in a certain oil storage tank explodes due to some special circumstances, the flame of the explosion is extinguished through the flame arrester 2, and the high pressure generated by the explosion enters the breakaway valve 5 through the check valve 3, and the breakaway valve 5 is under the action of pressure. Automatic disconnection, the pipeline stops working, and the check valve 3 is closed after stopping working, and the liquid in the pipeline no longer flows, which can prevent the flame from pouring back. At the same time, it also prevents the high pressure from being transmitted to other oil storage tanks, so as to protect other oil storage tanks.

[0050] When resuming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com