Cell delivery mechanism

A technology of conveying mechanism and battery cell, applied in conveyors, mechanical conveyors, secondary battery manufacturing, etc., can solve the problem of low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

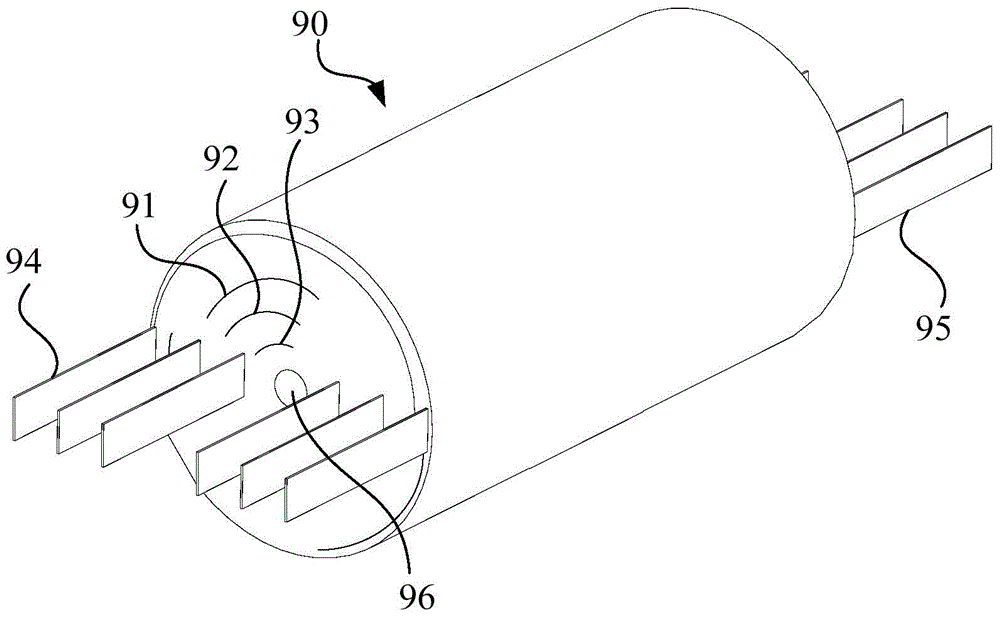

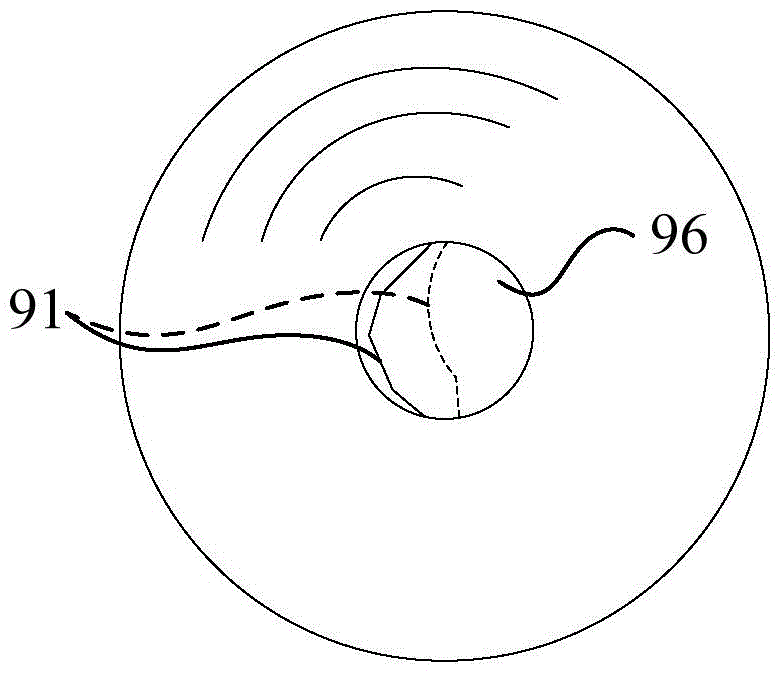

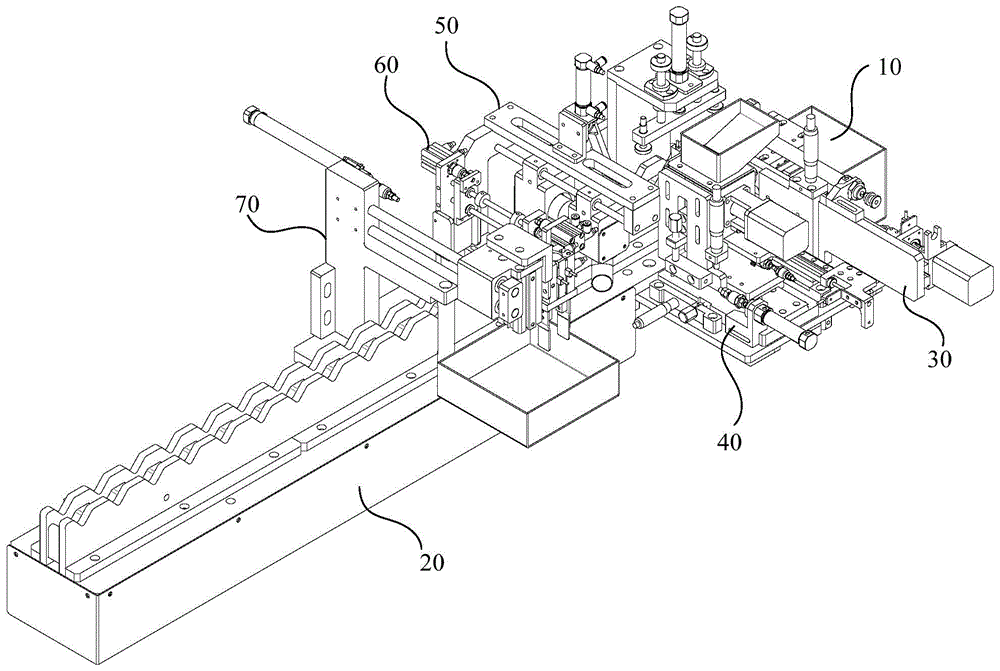

[0025] Such as image 3 and Figure 4 As shown, the cell processing device provided by an embodiment includes a screening mechanism 10 , a transmission mechanism 20 , a hole expansion mechanism 30 , a pipe threading mechanism 40 , a dust removal mechanism 50 , a short circuit test mechanism 60 and a defective product removal mechanism 70 . The screening mechanism 10 is arranged at the upstream end of the conveying mechanism 20 , and preliminarily screens the battery cells 90 to be processed. The screened battery cells 90 are placed on the conveying mechanism 20 and conveyed downstream by the conveying mechanism 20 . The hole reaming mechanism 30, the pipe threading mechanism 40, the dust removal mechanism 50, the short circuit testing mechanism 60 and the defective product rejecting mechanism 70 are arranged on the conveying path of the conveying mechanism 20 in sequence from upstream to downstream, wherein the reaming mechanism 30 is used for The shaft hole 96 of the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com