Lifting trolley

A technology of trolley and hoisting mechanism, which is applied in the direction of load block, load suspension components, hoisting device, etc., which can solve the problems of large crane volume, large site space, and multiple manufacturing materials, and achieve small volume and reduced space occupation , the effect of reducing energy loss and mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

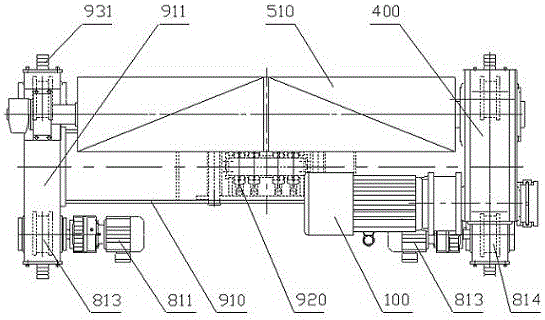

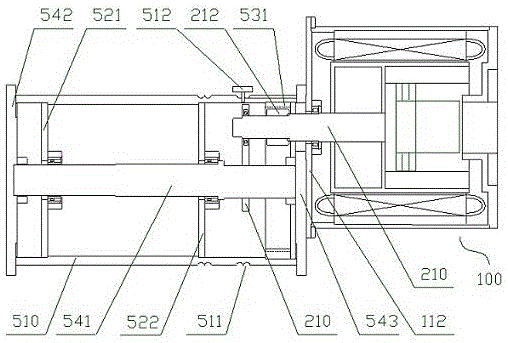

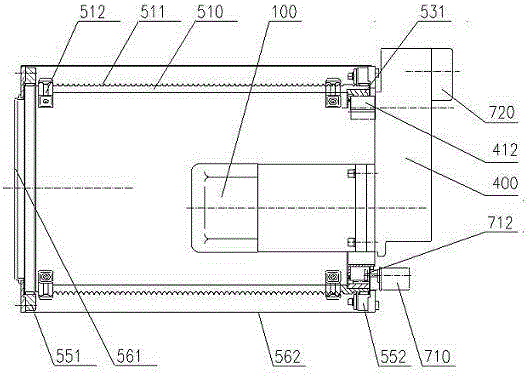

[0013] see Figure 1-6 The lifting trolley disclosed in the present invention includes a lifting mechanism, a running mechanism and a frame 910 for installing the lifting mechanism and the running mechanism, the lifting mechanism includes a reel 510 and a reel driving device, and the reel The drum is rotatably connected with the frame, and a rope groove 511 can usually be set on the outer surface of the drum, and a rope pressing plate or other rope fixing device 512 is provided. The driving device of the drum is based on a permanent magnet synchronous motor 100 The prime mover, the inner wall of the reel is provided with an inner ring gear 531, the drive output gear of the reel driving device meshes with the inner ring gear of the reel, and the fixed pulley in the pulley block 920 matched with the reel is usually It can be installed on the frame through corresponding brackets, and the traveling mechanism includes traveling wheels 813, 814 and traveling driving devices. On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com