An integral construction method of hanging baskets and cover beam brackets in the straight section of side spans of continuous rigid frame bridges with high piers

An integral construction, rigid-frame bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increased construction cost and technical difficulty, long construction period, complicated construction procedures, etc., and achieve simplified construction procedures and less materials. , The effect of supporting the system is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

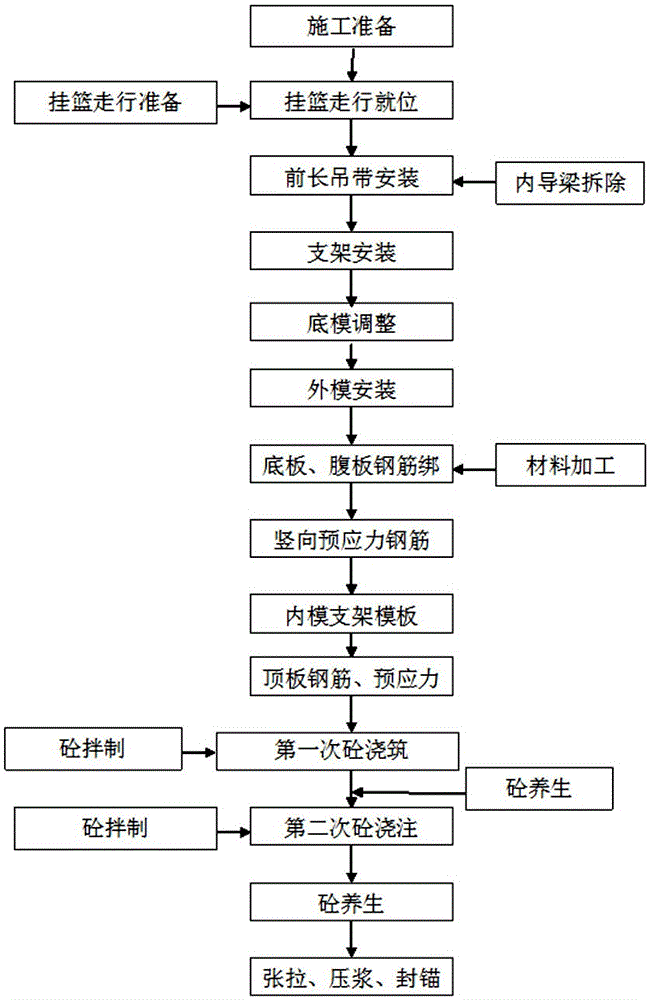

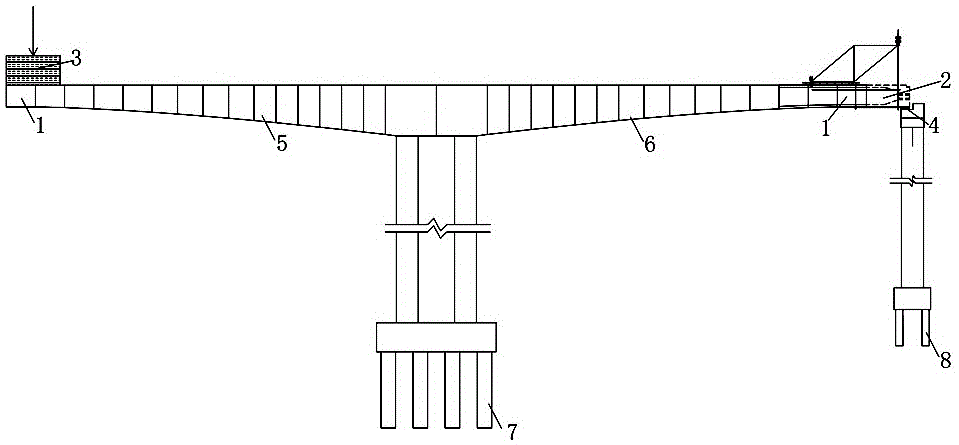

[0022] Such as figure 1 and figure 2 As shown, the overall construction method of the hanging basket on the straight section of the side span of the high-pier continuous rigid frame bridge and the cover beam support is: the steel bars are bound and formed at one time, and the pouring is carried out in two times; that is, the hanging basket is used for the first time. One section, the remaining solid section in the second pouring, most of the solid section falls on the cover beam, and only a small part falls on the hanging basket. see figure 1 , the high-pier continuous rigid frame bridge includes the middle pier 7, the side pier 8, and the mid-span 5 and side span 6 supported on the middle pier 7 and the side pier 8, wherein the mid-span 5 and the side span 6 in the middle are poured beam sections The side is the straight line sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com