A buffer device with high energy consumption and large deformation

A cushioning device and large deformation technology, applied in building components, earthquake resistance, etc., can solve the problems of limitations and high complexity of damping devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

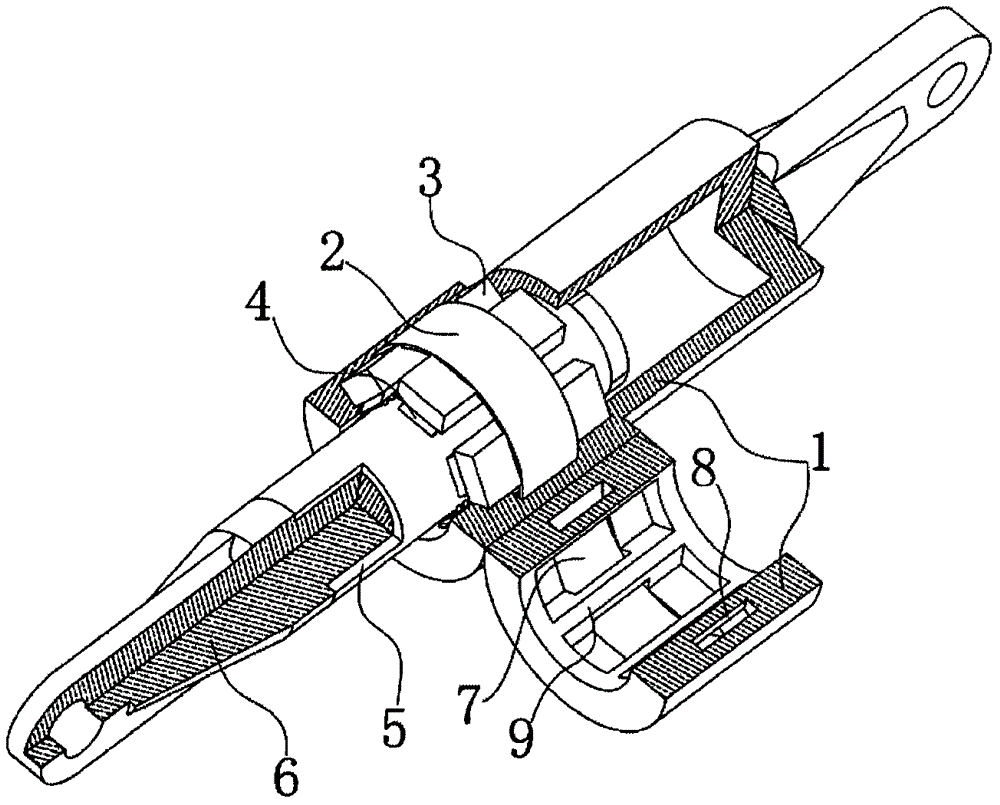

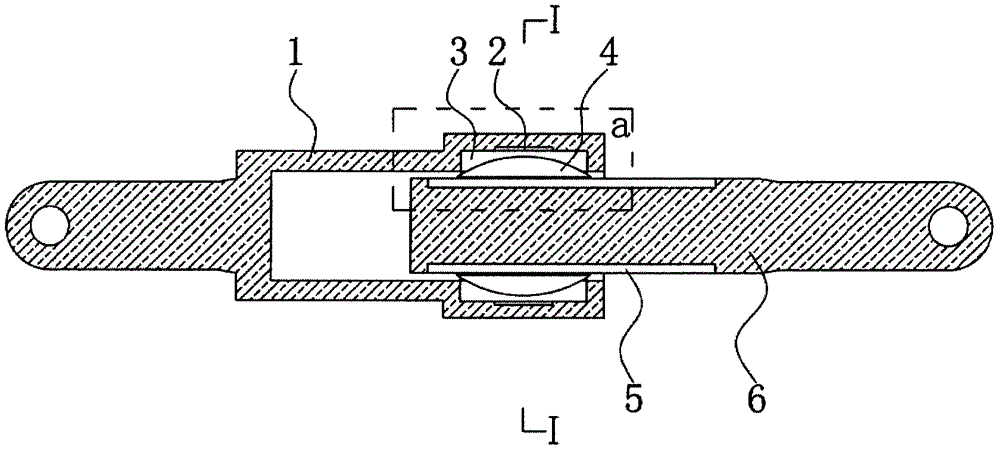

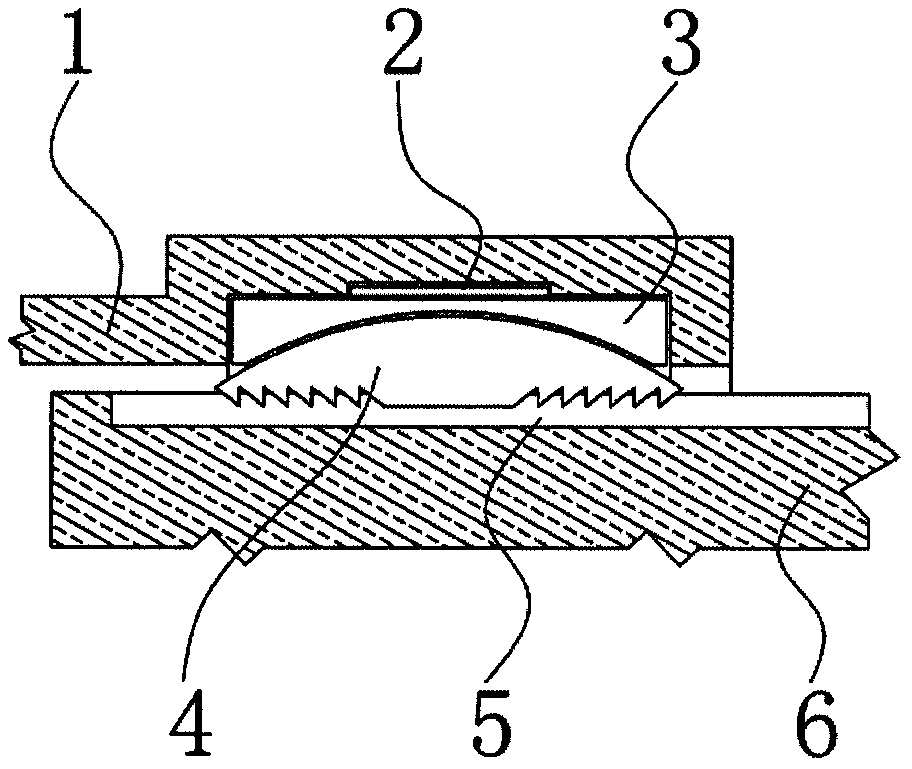

[0041] A high-energy-consuming large-deformation buffer device, its three-dimensional cut-away diagram is shown in figure 1 , Image 6 As shown, the main components include: shell 1, shape memory alloy ring 2, chute 3, shuttle claw 4, loss layer 5, movable rod 6; there are hinged holes at both ends of the device for connecting with other structures, and the overall shape is rod columnar; as Figure 2-Figure 5 As shown, the shape memory alloy ring is surrounded by a shape memory alloy strip with a rectangular cross section. There are 6 chutes and 6 shuttle claws respectively. There are 6 partitions with gaps inside the shell to connect the chute.

[0042] Optimization of device size:

[0043] (1) First: determine the starting force f of the device itself s and motion resistance f d , can be estimated from the following empirical relationship: f s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com