Bellows mechanical seal structure for petrochemical industry

A mechanical seal and petrochemical technology, which is applied in the field of petrochemical bellows mechanical seal structure, can solve the problems of reduced sealing performance of the sealing ring end face, easy deformation of the sealing ring, and large leakage, so as to improve the sealing performance and sealing effect, The overall deformation is small, and the effect of sealing fit is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

[0016] The inside and outside described in the present invention are determined by the position relative to the central axis 4 , the inner side is close to the central axis 4 , and the outer side is far away from the central axis 4 .

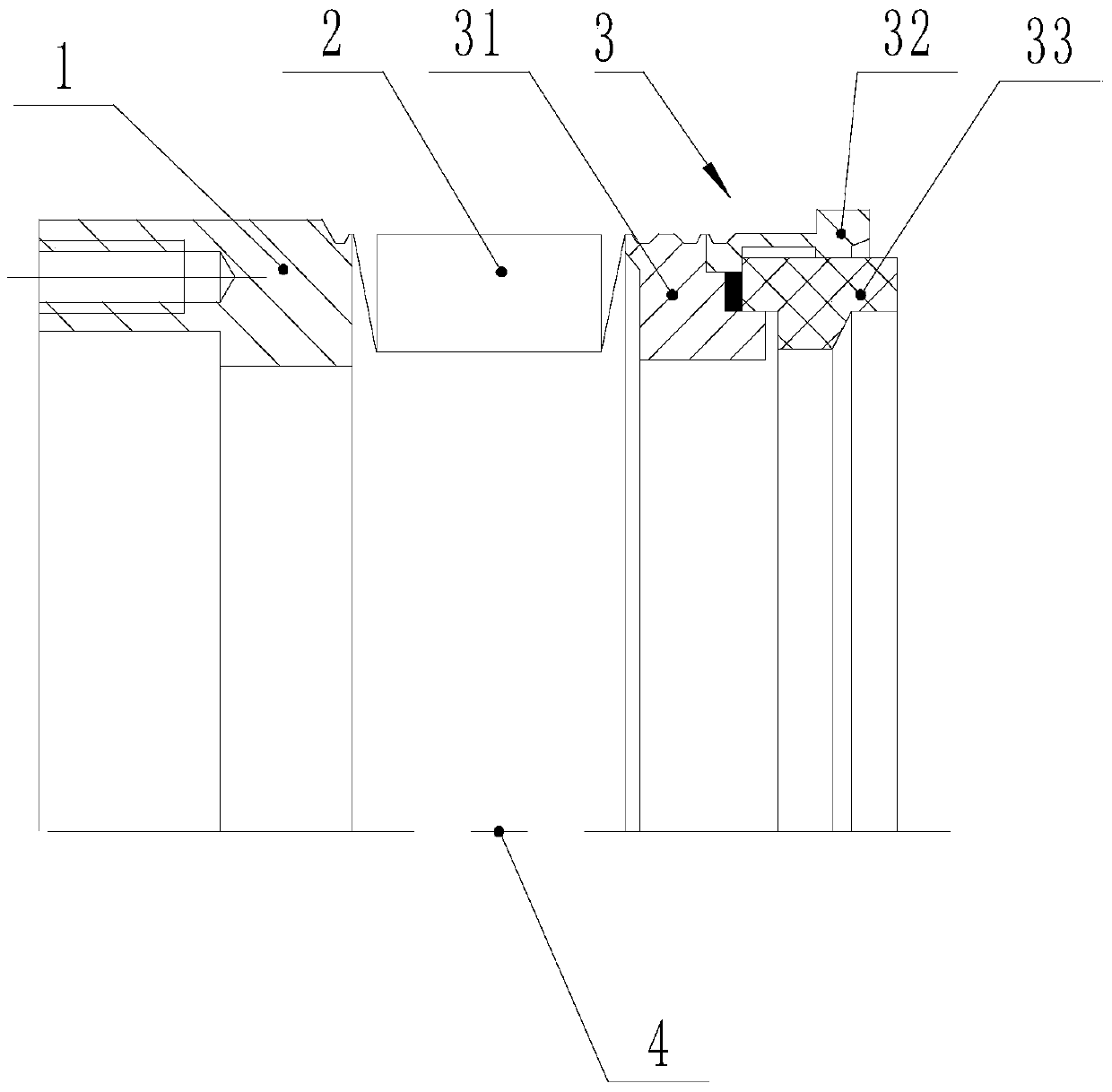

[0017] figure 1 Shows the current existing bellows 2 mechanical seal structure, in the mechanical seal structure, the seal ring head 3 includes two structures, the seal ring head 3 includes a metal connector 34 for sealing with the end of the bellows 2 At the same time, it also includes a seal ring 33 located inside the metal connector 34. In this structure, when high-temperature hot oil is transported, the end face of the seal ring 33 will deform itself to reduce the sealing performance and leak a large amount of hot oil.

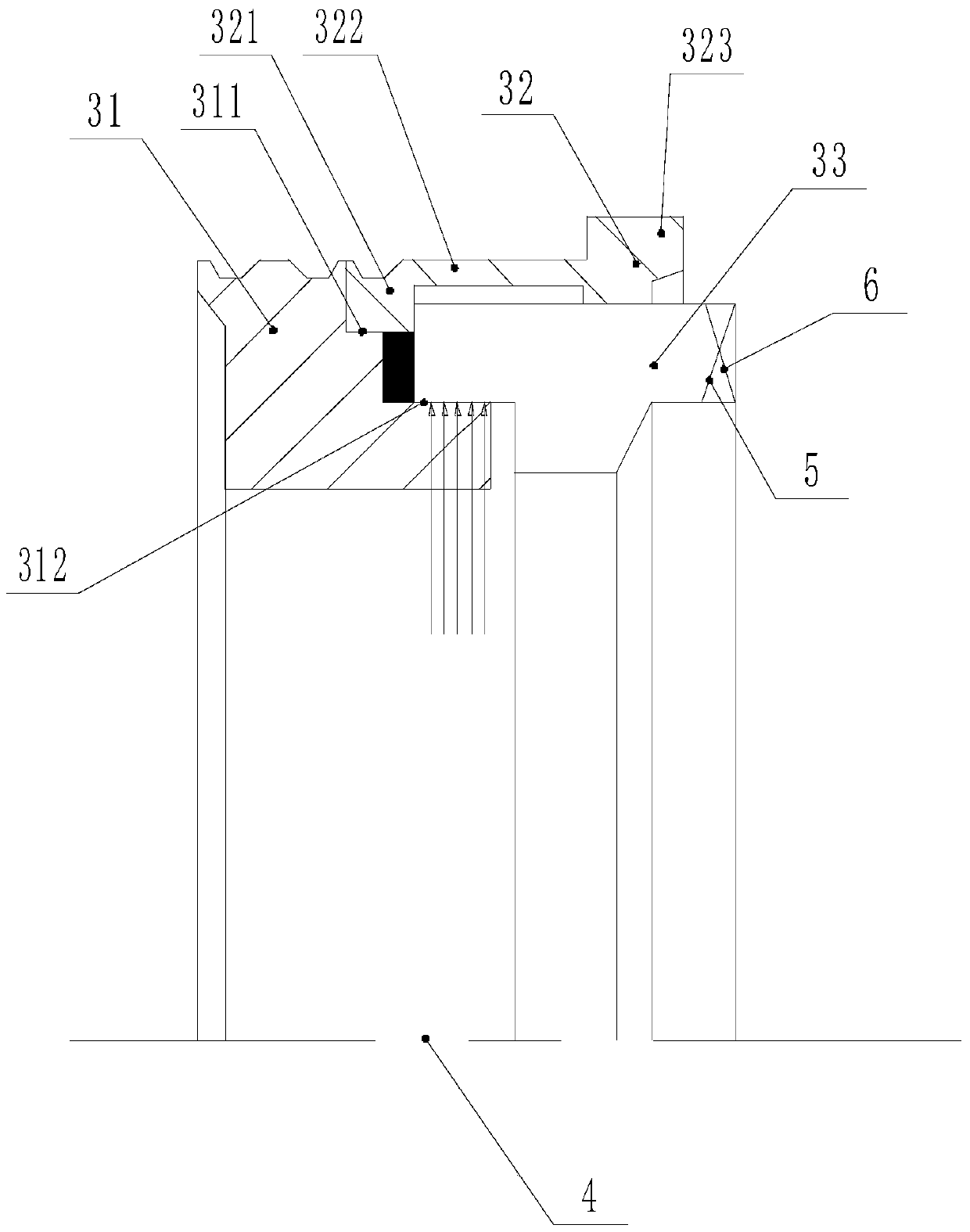

[0018] Such as figure 2 and image 3 As shown, a bellows 2 mechanical seal structure for petrochemical industry includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com