Sealing gasket used in plate heat exchanger

A technology for plate heat exchangers and sealing gaskets, applied in heat exchanger sealing devices, indirect heat exchangers, heat exchanger types, etc., can solve the problems of small flow rates, low flow rates, low heat transfer coefficients, and inconvenient maintenance , to save installation and maintenance costs, improve heat transfer coefficient, and prove the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

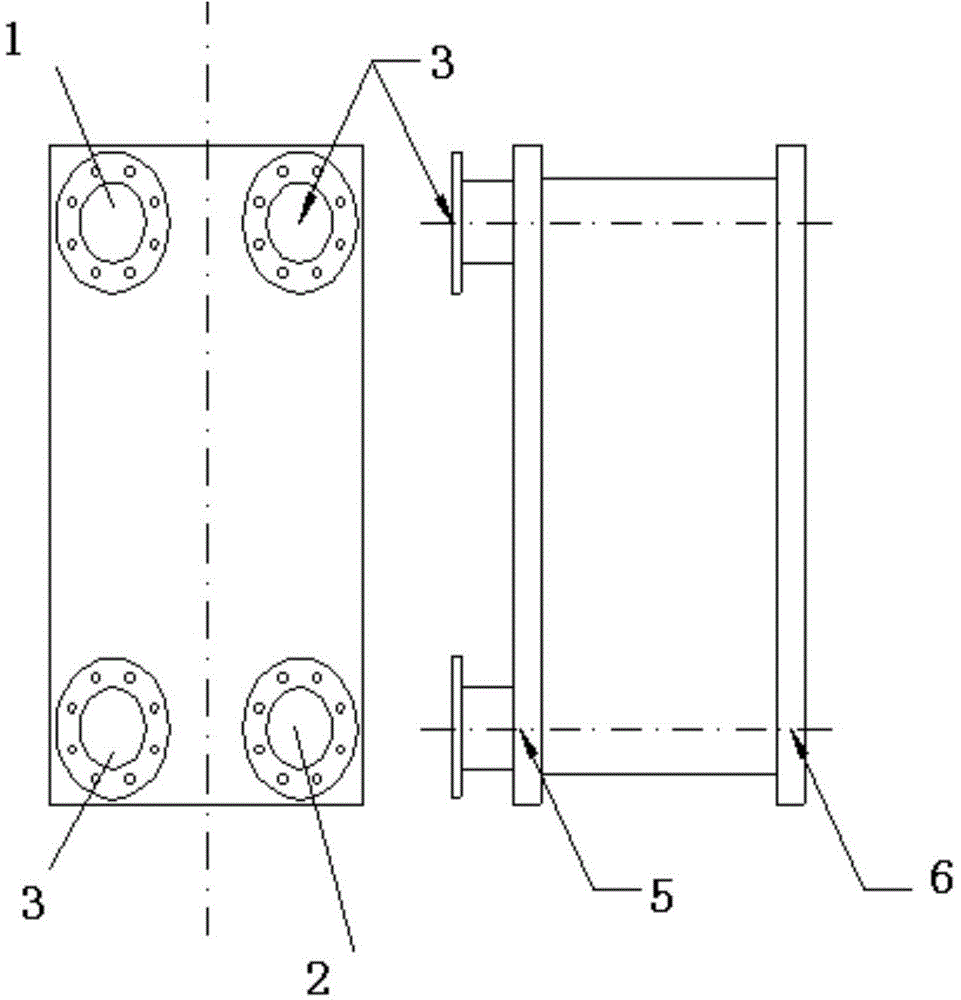

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

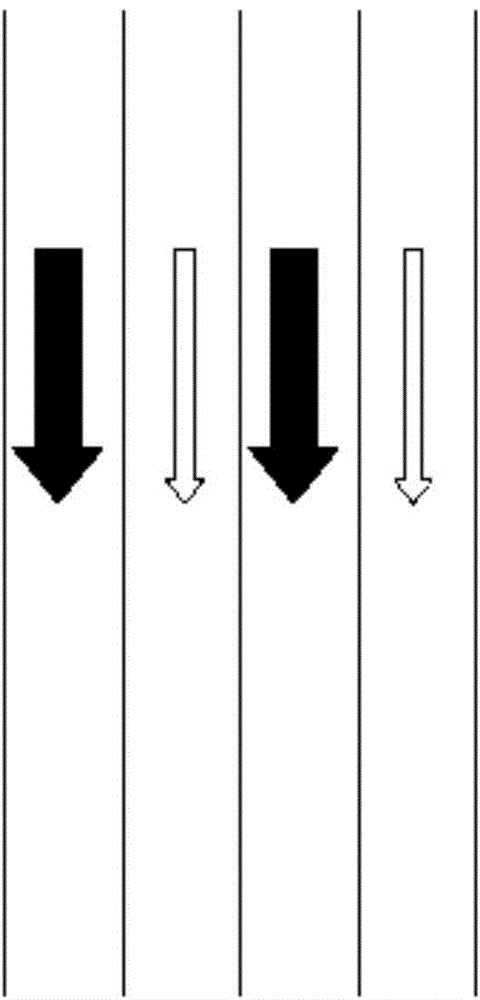

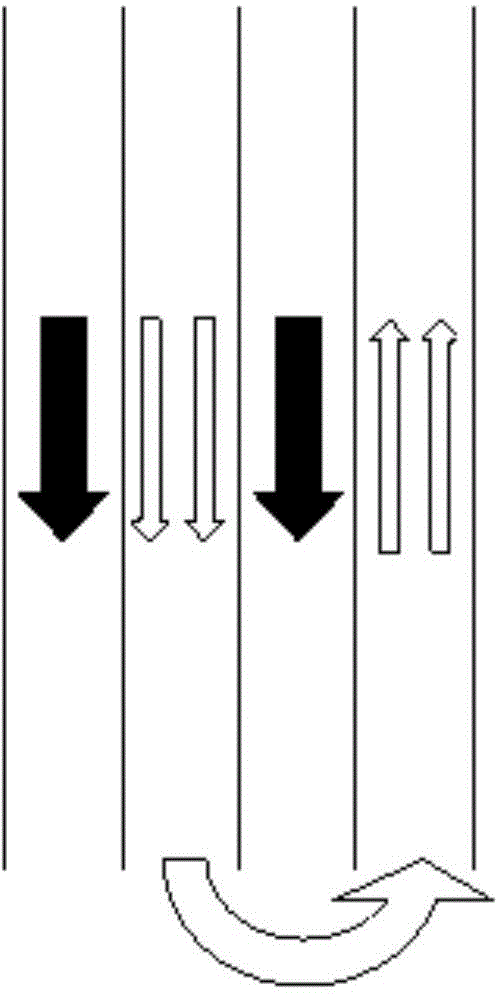

[0033] A heat exchange plate 10 used in a plate heat exchanger, wherein at least one flow splitting component is arranged in the heat exchange plate 10, and the flow path of the heat exchange fluid flowing through the heat exchange plate is divided into at least two There are three sub-pass flow channels 7, and the sub-pass flow channels 7 in the heat exchange plates 10 are in series structure. Through the series structure of the above-mentioned sub-range flow channels 7, the fluid passes through all the sub-range flow channels 7, such as Figure 6 As shown, the heat exchange fluid forms an S-shaped flow channel on the heat exchange plate 10 .

[0034] By setting the diversion parts, the fluid ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap