Self-capacitive touch screen structure, embedded touch screen and liquid crystal display

A self-capacitive, touch screen technology, applied in the direction of instruments, electrical digital data processing, optics, etc., can solve problems affecting display quality, achieve the effect of improving product display quality and reducing oblique line mura

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

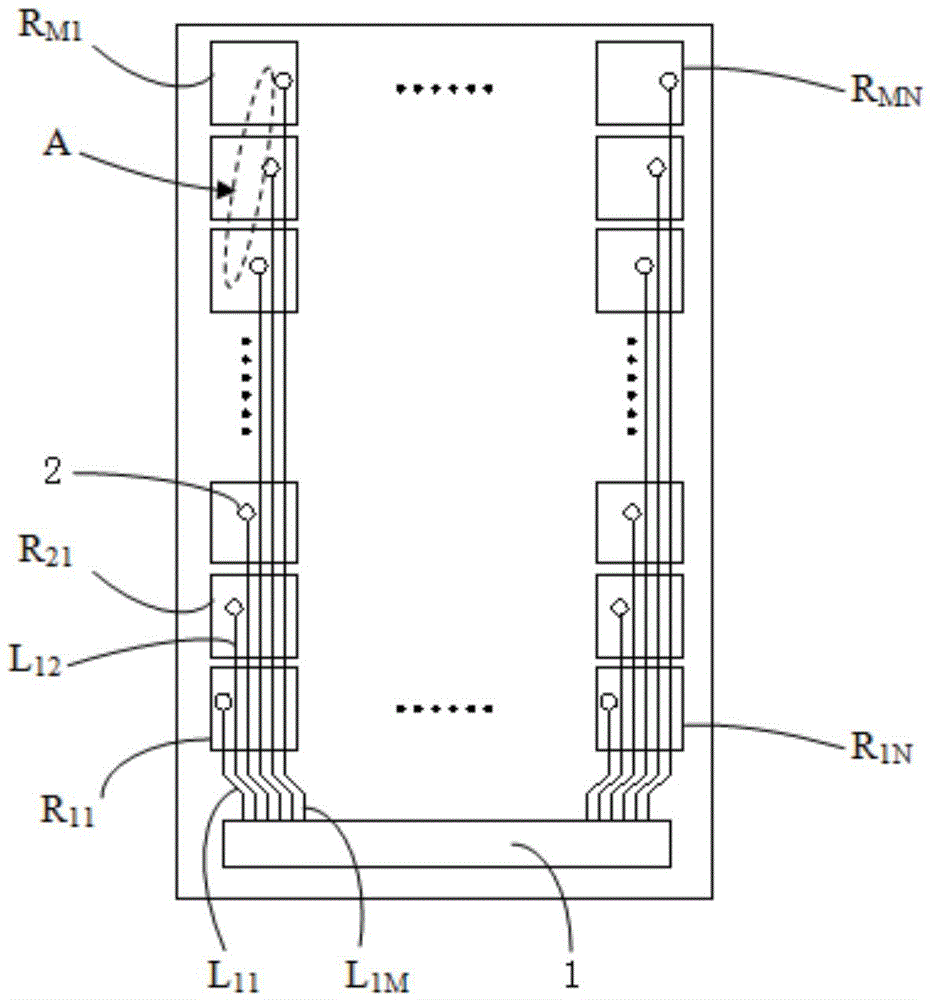

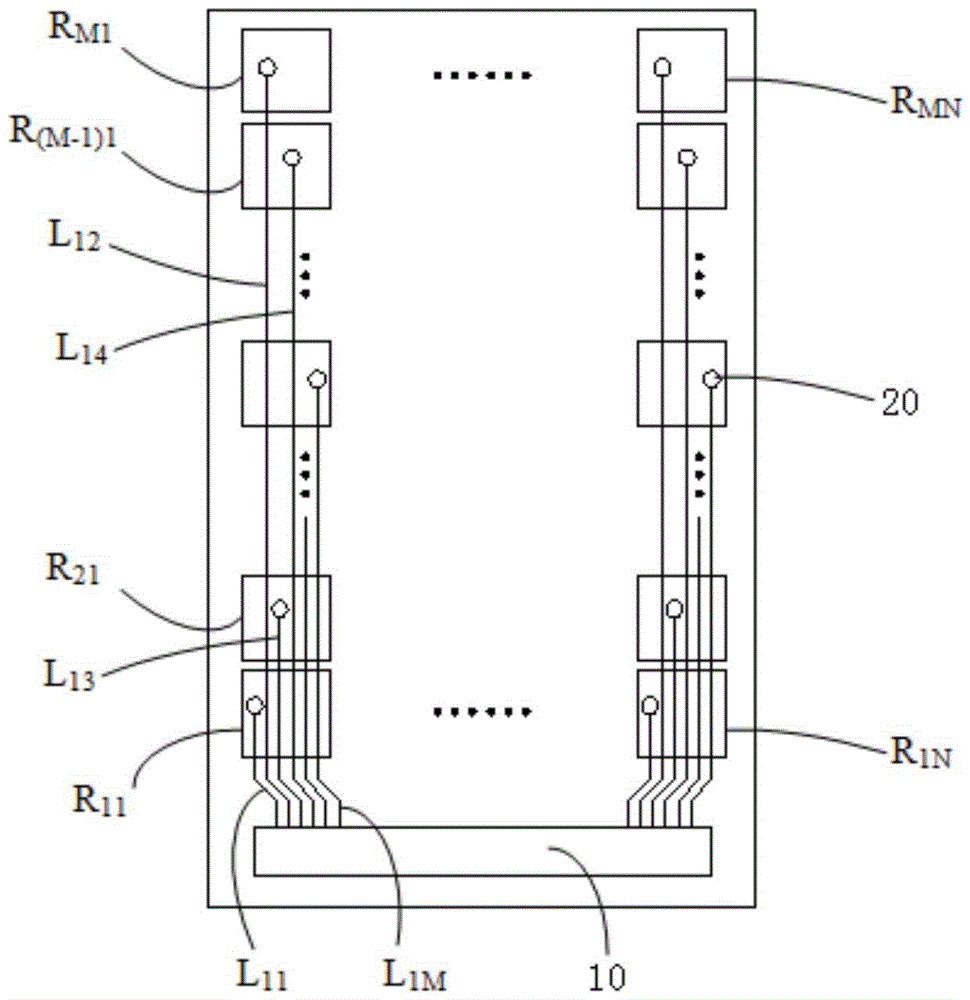

[0026] This embodiment provides a self-capacitive touch screen structure. Such as figure 2 As shown, the self-capacitive touch screen structure includes M rows×N columns of mutually insulated self-capacitance electrodes R xy (R 11 ~R M1 ~R 1N ~R MN) and the touch detection chip 10, each self-capacitance electrode R xy need to be connected via a separate trace L yx It is connected with the touch detection chip 10. Specifically, in this embodiment, the self-capacitance electrode R xy The shape is square, the self-capacitance electrode R xy and connecting trace L yx For the heterogeneous setting, the self-capacitance electrode R xy and connecting trace L yx The materials are all ITO, and the self-capacitance electrode R xy with the corresponding connection trace L yx It is electrically connected through the via hole 20 . In this embodiment, the number of via holes 20 is one. In some other embodiments, in order to improve the self-capacitance electrode R xy with th...

Embodiment 2

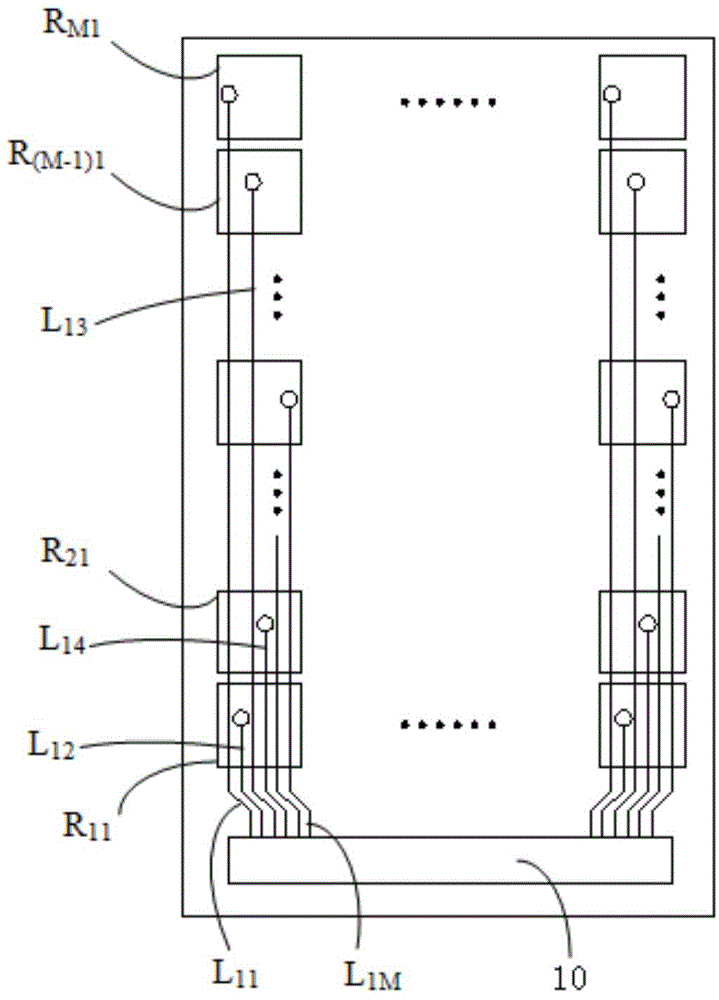

[0030] The difference between this embodiment and Embodiment 1 is that the connection order of the odd-group connection traces and the even-group connection traces is just opposite to that in Embodiment 1. Such as image 3 shown, still with the first column of self-capacitance electrodes R 11 ~R M1 As an example, the first column of self-capacitance electrodes R 11 ~R M1 connected by the first set of traces L 11 ~ L 1M Connect to touch detection chip 1. Among them, the group is connected to trace L 11 ~ L 1M It is divided into odd groups and even groups, and the odd group connection traces include the odd-numbered connection traces L 11 , L 13 , ..., the even-numbered connecting traces include the even-numbered connecting traces L 12 , L 14 ,... Among them, the odd group connects the trace L 11 , L 13 , ... from the column self-capacitance electrode R 11 ~R M1 Starting from the upper end, it is connected to the self-capacitance electrode R in turn M1 , R (M-1...

Embodiment 3

[0032] Such as Figure 4 As shown, this embodiment provides an in-cell touch screen 200 , which includes an upper substrate 201 , a lower substrate 202 and a liquid crystal layer 203 disposed between the upper substrate 201 and the lower substrate 202 . Further, the in-cell touch screen 200 also includes the self-capacitance touch screen structure 204 provided in Embodiment 1 or Embodiment 2; wherein, the self-capacitance electrodes and connecting wires in the self-capacitance touch screen structure 204 are all arranged on the The upper substrate 201 faces one side of the lower substrate 202 .

[0033] Such as Figure 4 Among them, this embodiment also provides a liquid crystal display, which includes the above-mentioned in-cell touch screen 200 and a backlight module 100, the in-cell touch screen 200 is arranged opposite to the backlight module 100, and the backlight module 100 provides The display light source is provided to the in-cell touch screen 200 so that the in-cell...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap