A Method of Electrical Compensation for Smart Skin Antenna Based on Embedded Fiber Bragg Grating

An intelligent skin antenna and fiber grating technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems such as the reduction of the electrical performance of the skin antenna, and achieve the effect of light weight and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

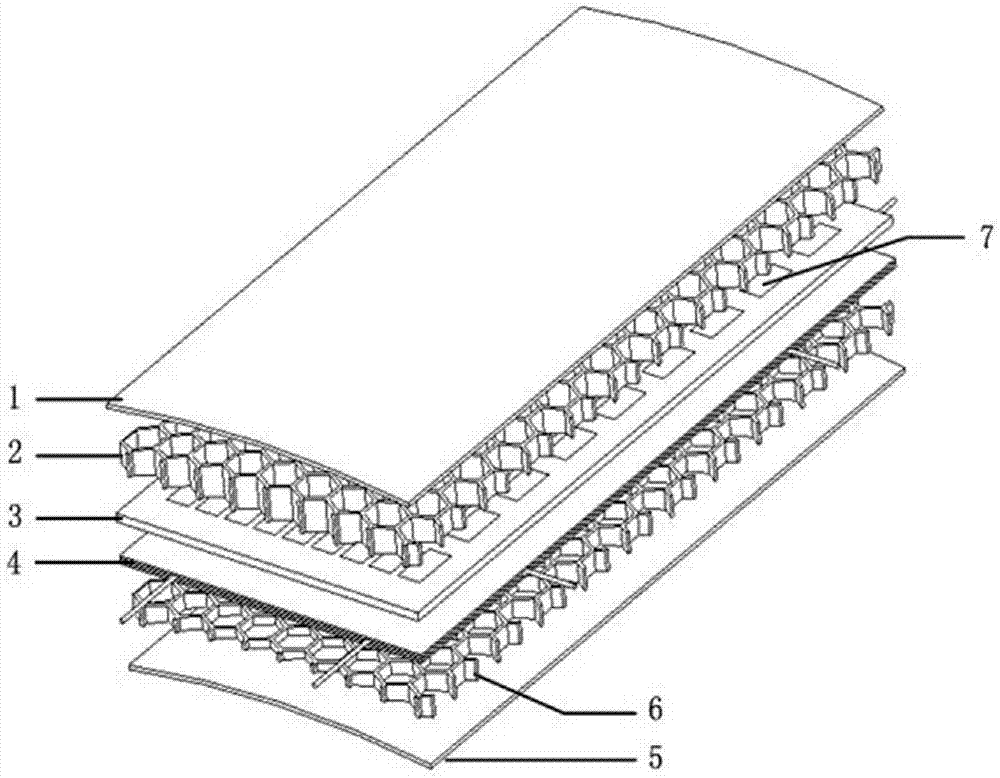

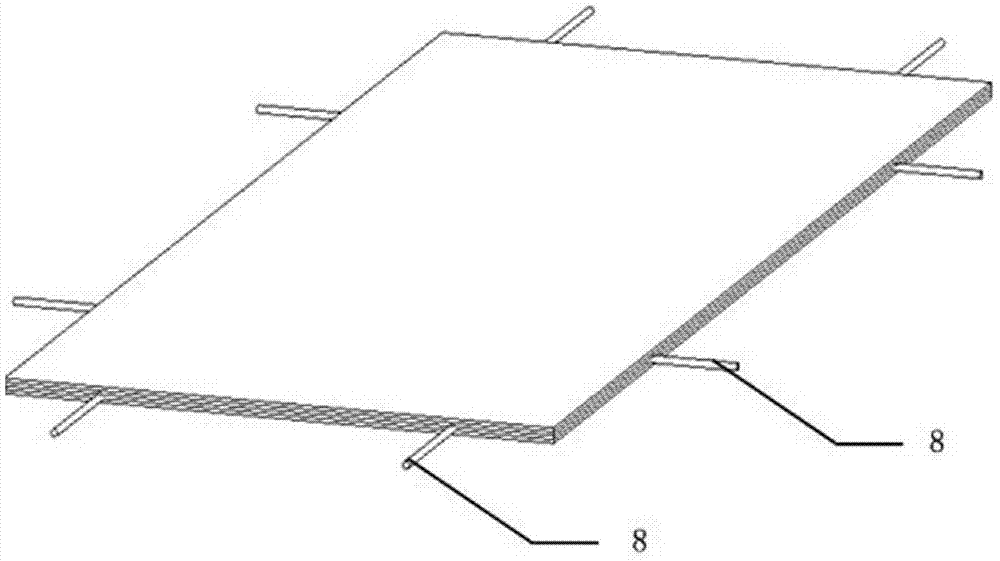

[0055] The electrical compensation method of the intelligent skin antenna of the present invention first embeds the fiber grating into the structure of the skin antenna, then uses the strain-displacement transformation matrix to convert the perceived strain into a deformation displacement, and finally modifies the structure of the skin antenna through the perceived deformation displacement The current is excited to achieve the purpose of compensating the influence of structural deformation on electrical performance.

[0056] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

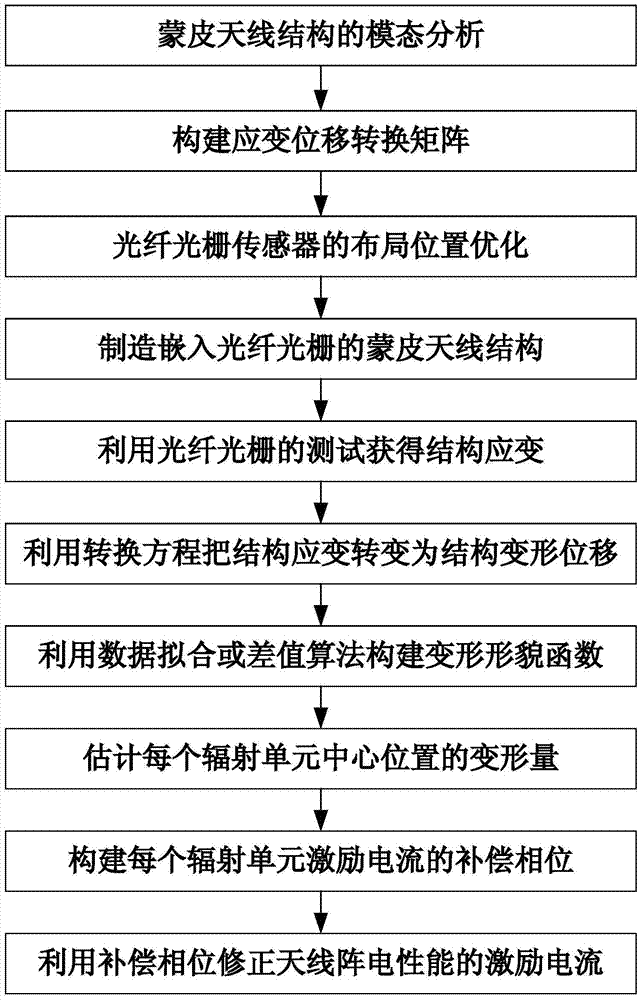

[0057] refer to figure 1 , the electrical compensation method of the intelligent skin antenna based on embedded fiber grating of the present invention, it comprises the following steps:

[0058] The first step is to establish the finite element model of the skin antenna structure by using ANSYS or NASTRAN software according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com