Parameter estimation and fitting method for collecting supporting point frequency in vibrating wire mode

A parameter estimation, vibrating wire technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of inaccurate frequency measurement, parameter estimation and fitting that cannot be measured, and achieve the goal of improving accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

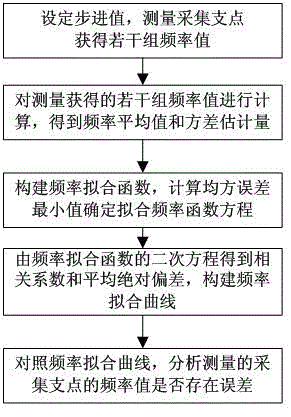

[0023] like figure 1 Shown, a kind of parameter estimation and fitting method that the present invention is used for vibrating wire type acquisition fulcrum frequency comprises the following steps:

[0024] Step 1. Set the step value, measure and collect the fulcrum to obtain several groups of frequency values;

[0025] Step 2. Calculating several groups of frequency values obtained by measurement to obtain the frequency mean value and variance estimator;

[0026] Step 3, constructing a frequency fitting function, calculating the minimum value of the mean square error to determine the fitting frequency function equation;

[0027] Step 4, calculate the mean square error fitting to obtain the quadratic equation of the frequency fitting function, obtain the correlation coefficient and the average absolute deviation by the quadratic equation of the frequency fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com