Transparent hidden holographic identification and manufacturing method thereof

A production method and transparent technology, applied in the field of marking products, can solve the problem of not being able to play the anti-counterfeiting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

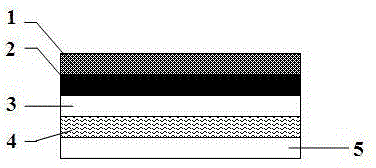

[0029] like figure 1 As shown, the transparent hidden holographic mark of the embodiment of the present invention is sequentially structured from the inside to the outside as a silicone oil bottom layer 5, a pressure-sensitive self-adhesive layer 4, a separable transparent layer 3, a transparent holographic information layer 2, and a transparent substrate layer 1; The transparent substrate layer 1 is made of PET film or sheet with a material thickness of 30 μm; the transparent holographic information layer 2 is made of acrylic resin by embossing a holographic image. The detachable transparent layer 3 is a UV photocurable resin coating, and after the detachable coating is coated on the transparent holographic information layer, the transparent holographic information layer 2 is completely or partially covered, and the coating material fills the holographic stripe gap Finally, according to design requirements, all or part of the holographic pattern can disappear, invisible to th...

Embodiment 2

[0040] The transparent hidden holographic mark of the embodiment of the present invention is structured sequentially from the inside to the outside as a silicone oil bottom layer 5, a pressure-sensitive self-adhesive layer 4, a separable transparent layer 3, a transparent holographic information layer 2, and a transparent substrate layer 1; the transparent substrate The material layer is made of PVC transparent plastic film or sheet, and the thickness of the material is 80 μm. The transparent holographic information layer 2 is made of acrylic resin by embossing holographic images. The detachable transparent layer 3 is a modified acrylic thermosetting resin coating, and after the detachable coating is coated on the transparent holographic information layer 2, the transparent holographic information layer 2 is completely or partially covered. After the holographic stripe gap, all or part of the holographic pattern can disappear according to the design requirements, and it is inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com