Power battery box of electric car and electric car

A technology for power batteries and electric vehicles, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of low temperature regulation efficiency and complex structure of the battery box, and achieve the effect of simple structure, high temperature regulation efficiency and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

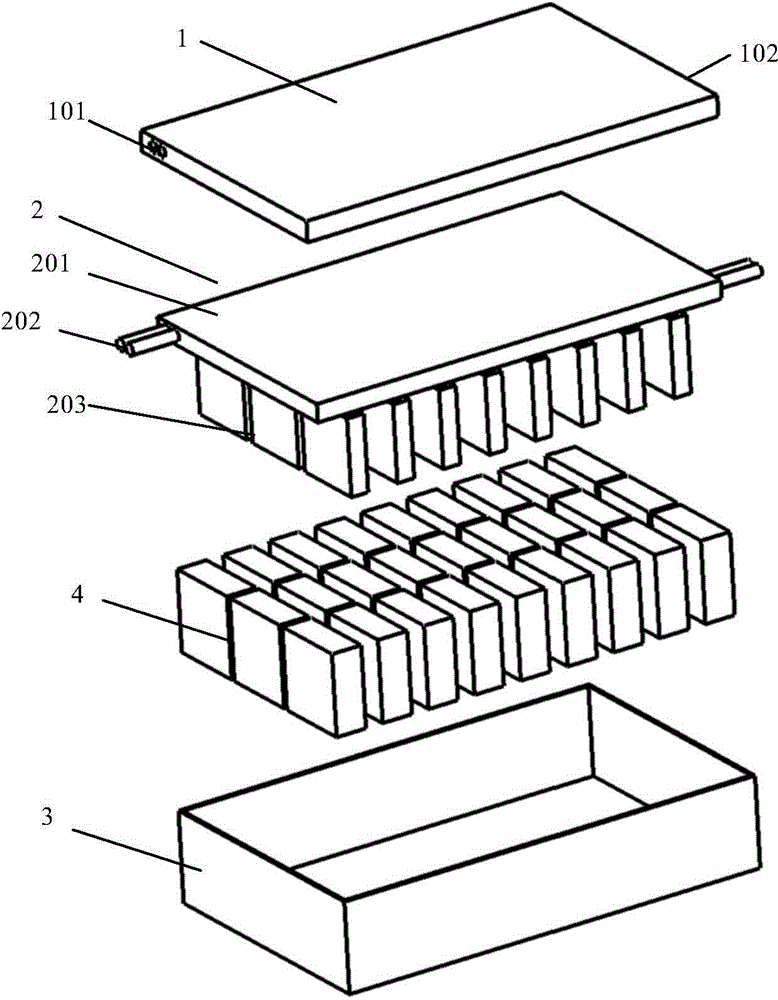

[0017] figure 1 A schematic diagram of an exploded structure of an electric vehicle power battery box provided by an embodiment of the present invention, such as figure 1 As shown, the electric vehicle power battery box provided by the present invention includes:

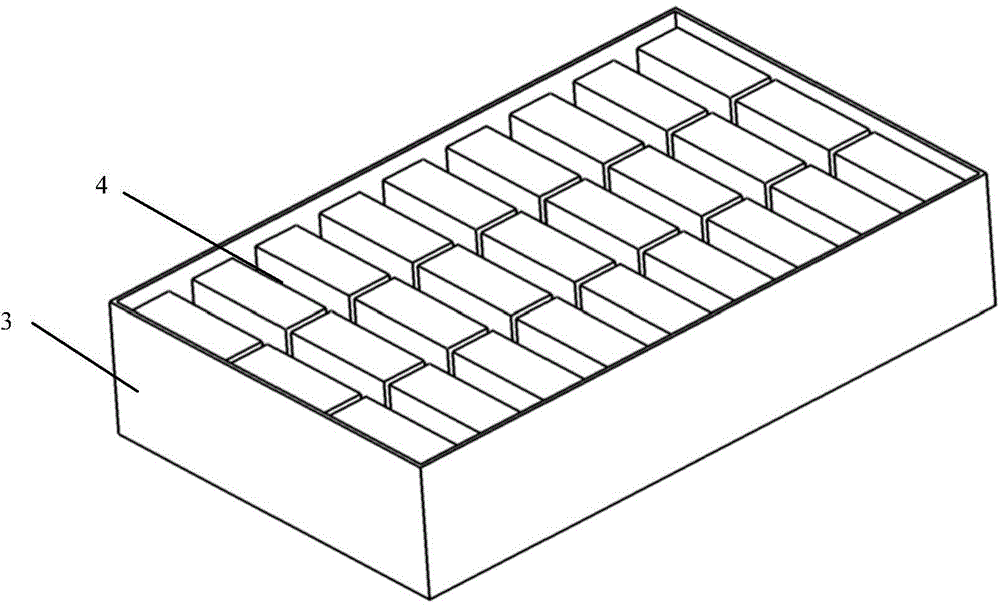

[0018] Battery box cover 1, battery box body 3, temperature control module 2 and battery array 4;

[0019] The battery array 4 is fixedly arranged in the battery box 3, the battery array 4 is composed of a plurality of battery modules, and gaps are left between the plurality of battery modules;

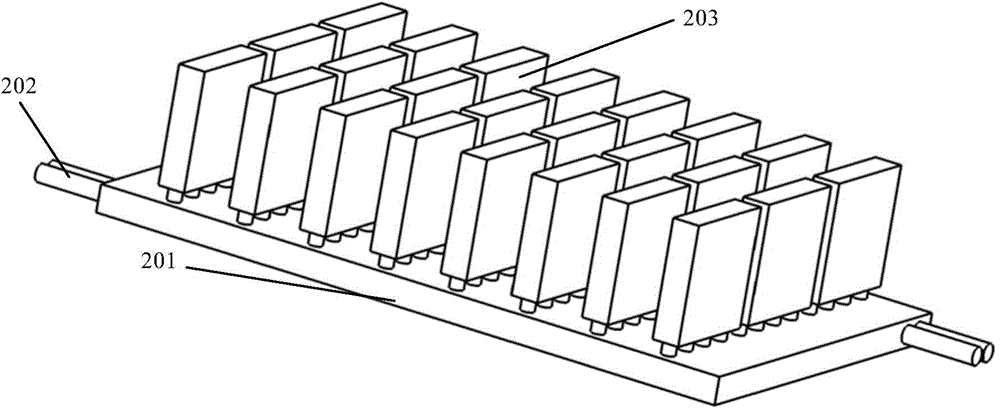

[0020] The temperature control module 2 includes a circulation pipeline 202, a fixed plate 201 and a heat dissipation array 203 composed of heat sinks. Each heat sink is fixed on the fixed plate 201 through the circulation pipeline 202. The fixed The plate 201 is embedded on the battery box cover 1; the circulation pipeline 202 is used to transmit the heat transfer fluid medium;

[0021] Each heat sink is inserted betwee...

Embodiment 2

[0031] On the basis of the first embodiment above, the electric vehicle power battery box provided in this embodiment further includes:

[0032] A central control element and a temperature sensor connected to the central control element, the temperature sensor is arranged on the battery box, and the temperature sensor is used to detect the heat dissipation temperature of the battery array;

[0033] The central control element is used for controlling the transmission of the heat transfer fluid medium according to the heat dissipation temperature.

[0034] Specifically, the temperature sensor transmits the temperature information collected from the battery box to the central control component, and the central control component analyzes the received temperature information, and searches for the corresponding control strategy among the preset control strategies according to the analysis results , the central control component controls the temperature of the battery box according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com