Method for producing a valve device and corresponding valve device

A valve device and valve block technology, which is applied in the field of valve device manufacturing, can solve problems such as large material consumption, and achieve the effects of high surface quality and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

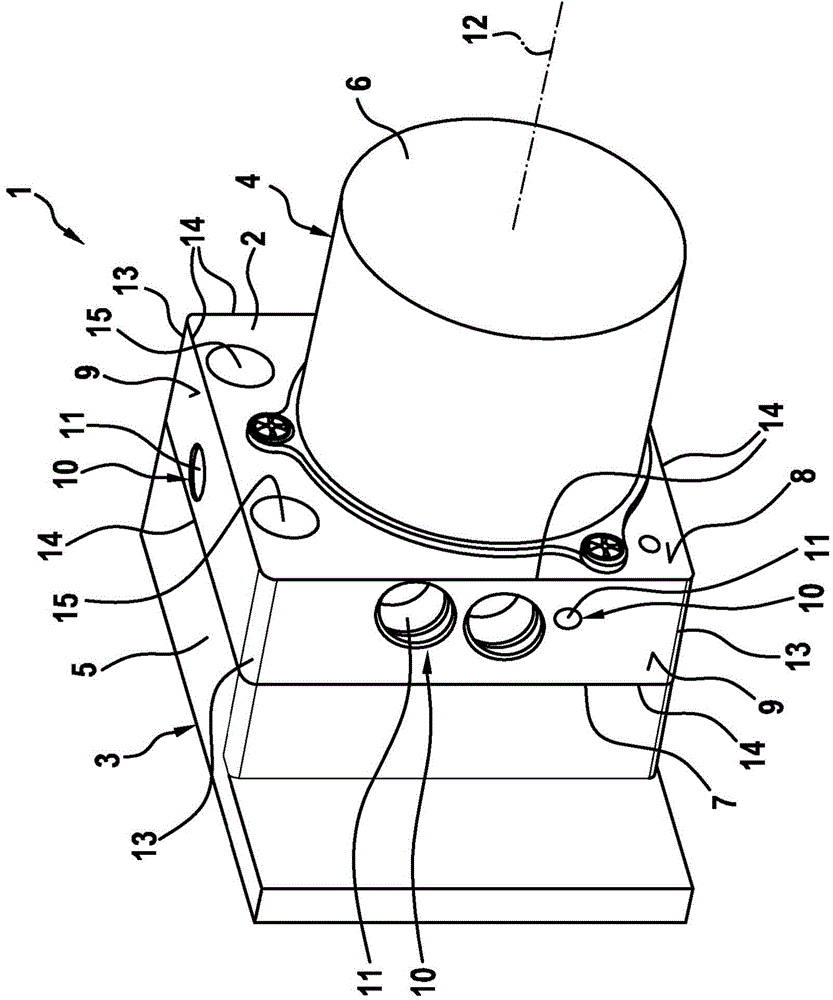

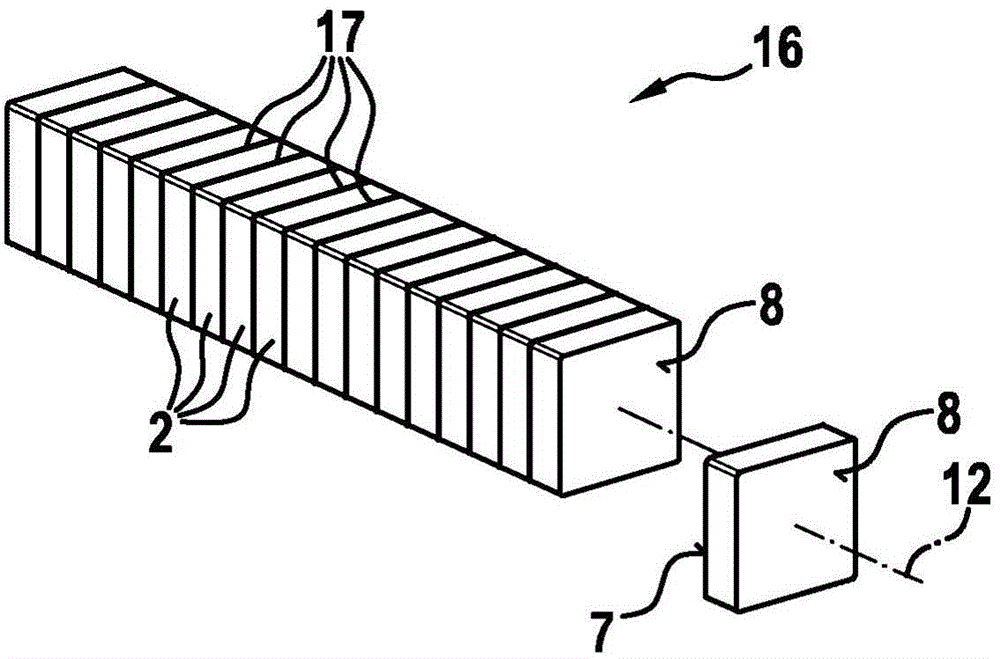

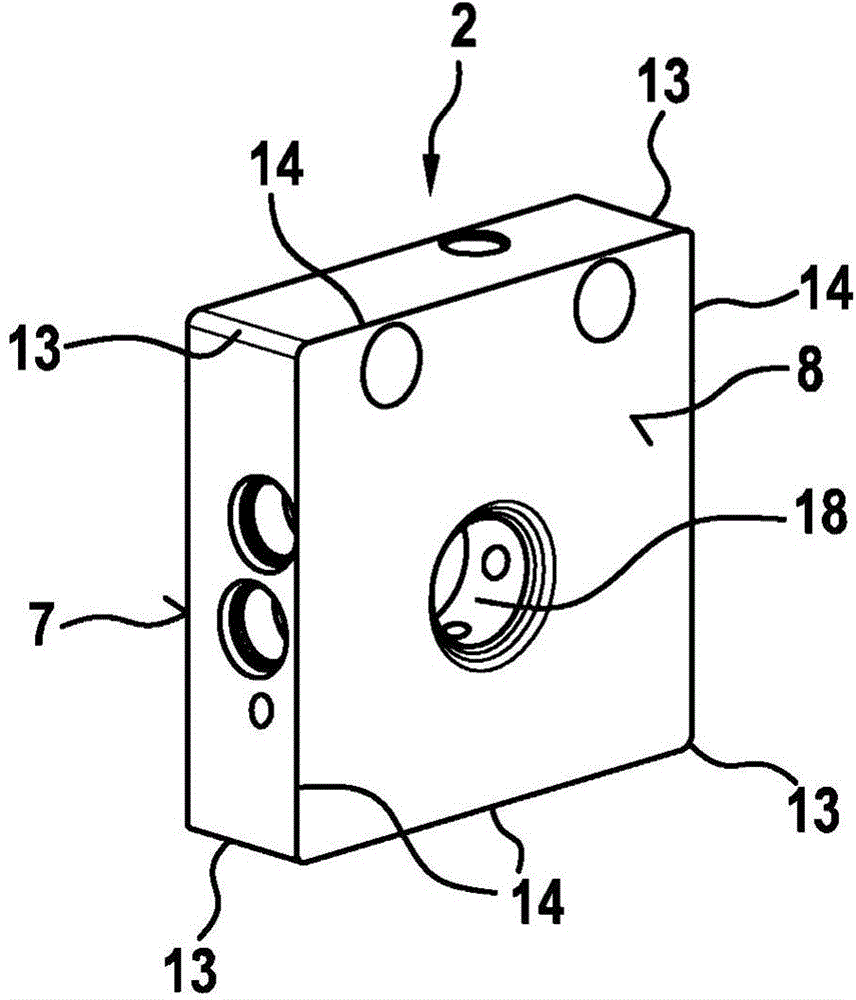

[0026] figure 1 A valve arrangement 1 is shown with a valve block 2 , which can also be referred to as a hydraulic assembly. Furthermore, valve device 1 has a plurality of accessories 3 and 4 , of which, for example, accessory 3 is present as a controller and accessory 4 is present as a pump motor, from which housing 5 or 6 respectively can be seen. The accessories 3 and 4 are fastened directly or indirectly to the valve block 2 , wherein they are respectively fastened against the contact surface 7 or 8 . Apart from the contact surfaces 7 or 8 present in the form of the end faces of the valve block 2 , the valve block has four sides 9 , only two of which are visible here. A number of fluid lines 10 are provided in the valve block 2 , only some of which are marked here as examples. For example, the fluid line 10 passes through at least one of the contact surfaces 7 and 8 or at least one of the side surfaces 9 or any desired combination of these surfaces when the opening 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com