Sponge sofa structure

A sofa and sponge technology, applied in the field of sofas, can solve problems such as unsatisfactory cushioning performance, heavy sofa weight, and low production efficiency, and achieve the effects of improving market competitiveness, reducing usage and weight, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

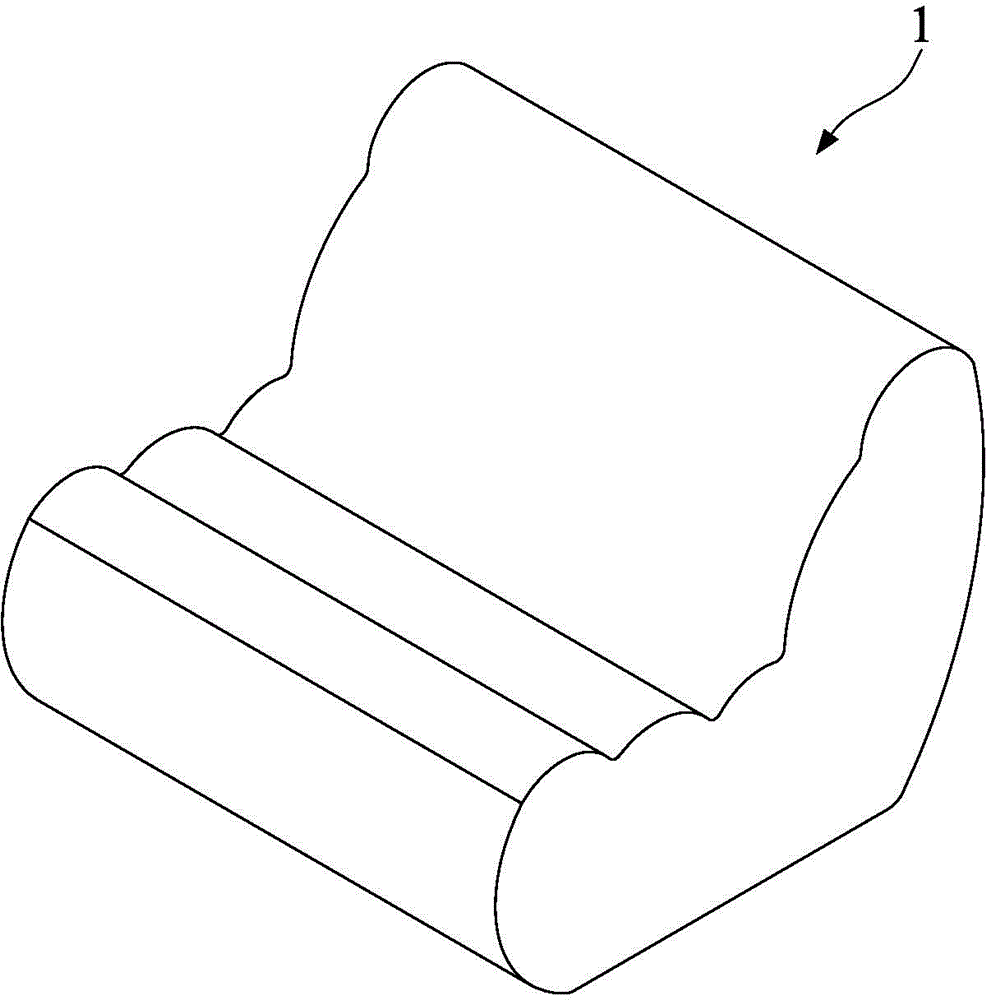

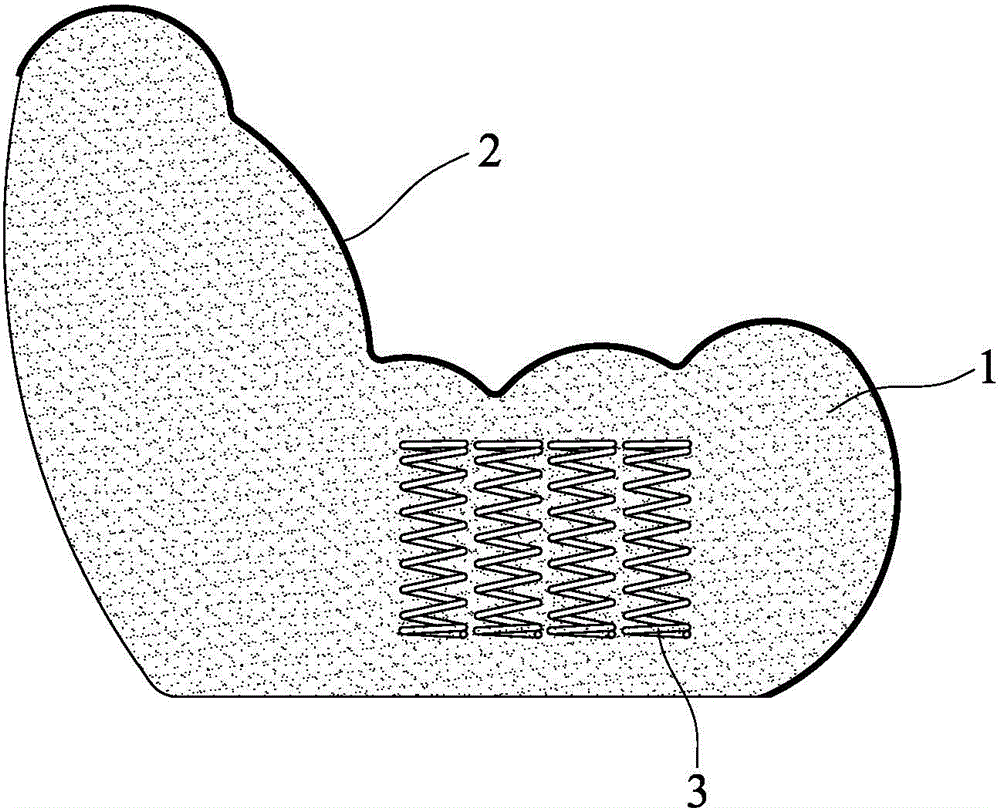

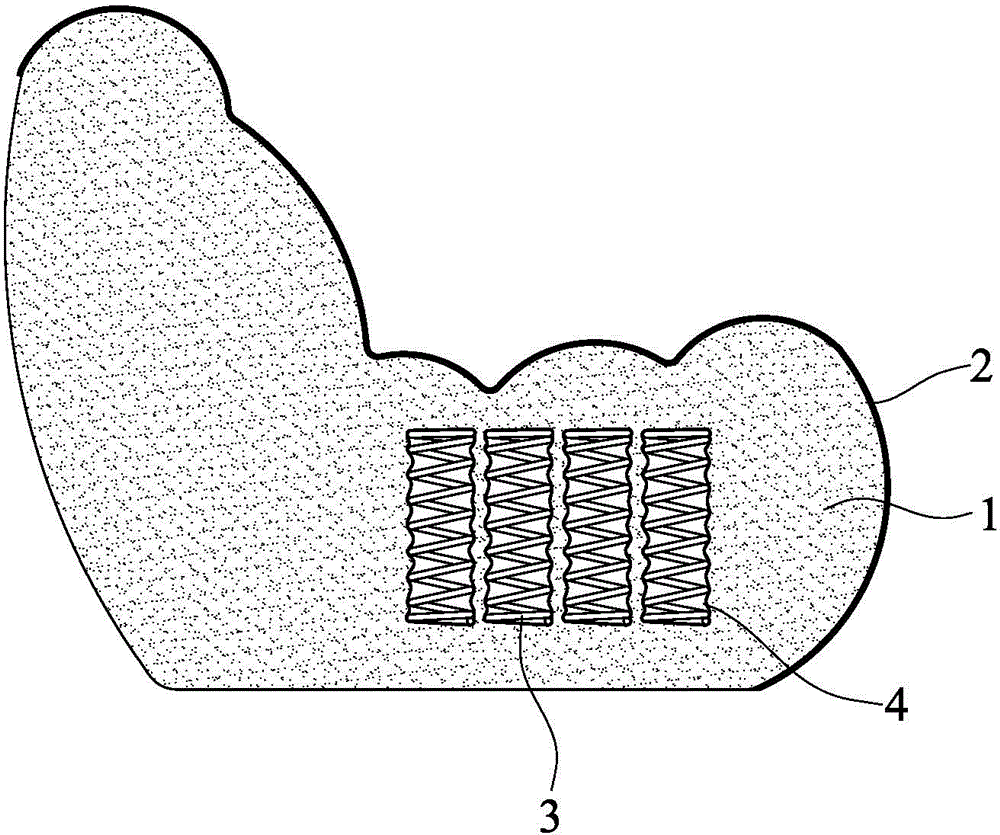

[0017] Such as Figure 1 to Figure 3 As shown, the present invention discloses a sponge sofa structure, which includes a hard sofa base 1, and the hard sofa base 1 is a hard foam sponge. The upper surface is covered with a layer of soft sponge layer 2. Of course, this soft sponge layer 2 can cover the surface of the visible parts of the entire sofa, that is, the surface of other parts except the bottom surface of the sofa, so as to ensure that the sofa can touch the parts. The softness prevents the user from colliding with the sofa and causing discomfort.

[0018] Such as figure 1 As shown, the key of the present invention is: at least a plurality of springs 3 are set in the seating portion 12 of the sofa base 1, each spring 3 is directly fixed in the sofa base 1 when passing through the foam sofa base 1, each spring 3 The axis is arranged vertically to the surface of the seating portion 12 .

[0019] Furthermore, a plurality of springs 3 can also be arranged in the backres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com