Cone sand maker crushing wall being smaller than 2000 mm in diameter and manufacturing method

A technology of cone sand making machine and crushing wall, applied in grain processing and other directions, can solve the problems of broken wall wear, small wear state, serious wear, etc., and achieve the effect of reducing the use cost, prolonging the service life and reducing the cost of sand making.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

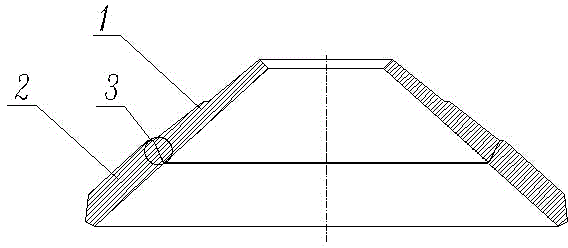

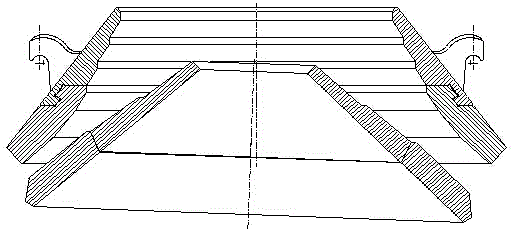

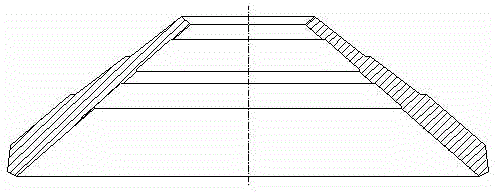

[0011] Example 1: Refer to the attached Figure 1-2 . A cone sand maker crushing wall with a diameter of less than 2000mm, the upper part 1 of the crushing wall is made of Mn13, and the lower part of the crushing wall 2 is made of high-chromium cast iron. The lower end surface of the upper part 1 of the crushing wall is an annular outer inclined surface, and the upper end surface of the lower part 2 of the crushing wall is an annular inner inclined surface and coincides with the upper end surface 3 of the upper part 1 of the crushing wall. The height of Mn13 crushing wall 1 is greater than that of high chromium cast iron crushing wall 2. The material of Mn13 broken wall is ZGMn13-1, ZGMn13-2, ZGMn13-3, ZGMn13-4, ZGMn13-5. The material of high chromium cast iron crushing wall is Cr15 or Cr26.

Embodiment 2

[0012] Example 2: On the basis of Example 1, a method for manufacturing the broken wall of a cone sand making machine with a diameter of less than 2000mm. (1) The lower part of the broken wall is made according to conventional techniques, and the lower part of the broken wall is cast. Placed on a high-frequency vibration platform, cast molten high-chromium cast iron into the casting mold of the lower part of the broken wall under the vibration of the high-frequency vibration platform. After cooling and demolding, the lower part of the broken wall is obtained, and then the lower part of the broken wall is heat treated and processed; ( 2) Make the upper part of the broken wall casting mold according to the conventional technology, place the finished upper part of the broken wall casting mold on the high-frequency vibration platform, and cast the molten high manganese steel into the upper part of the broken wall under the vibration of the high-frequency vibration platform After coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com