An Improved Piezoelectric Chip Type Ultrasonic Transducer

An ultrasonic and transducer technology, applied in the field of transducer structure, to achieve the effect of increasing the area, simplifying the structure of components, flexible in design and use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited thereto.

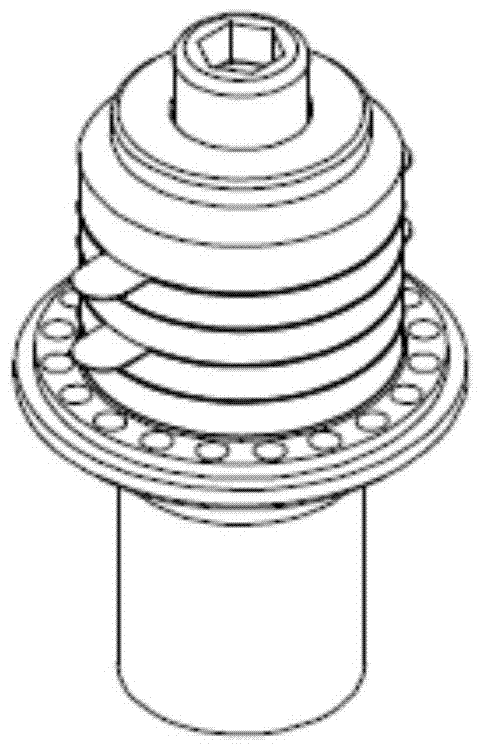

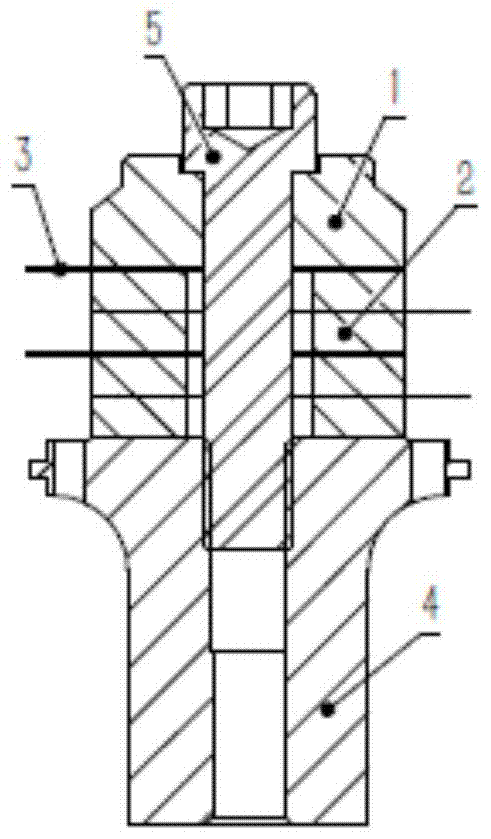

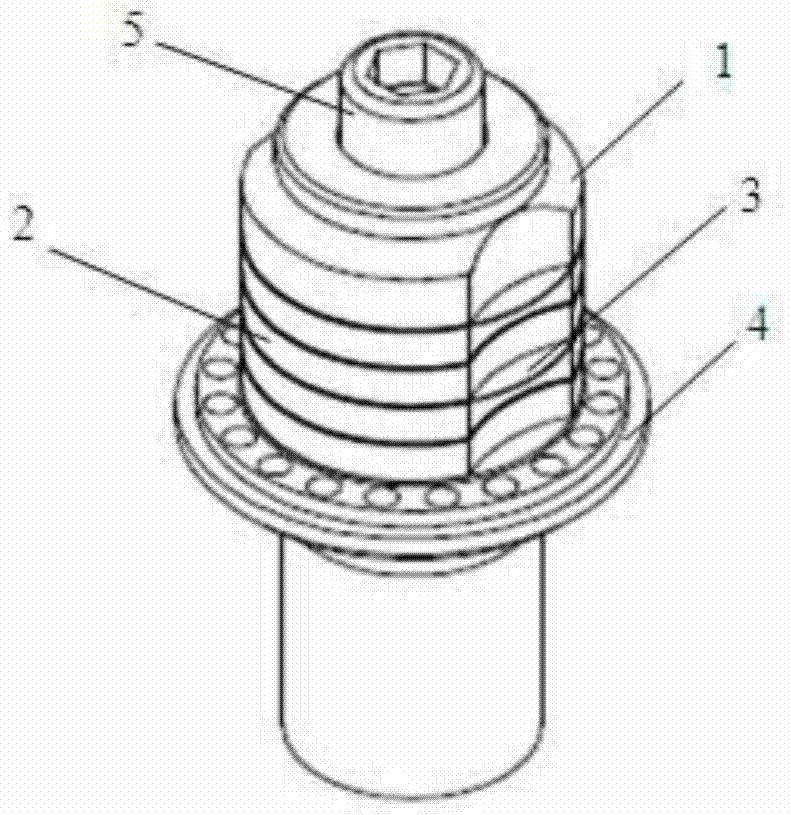

[0024] The ultrasonic transducer of the present invention comprises rear cover plate 1, ceramic sheet 2, electrode sheet 3, front cover plate 4 arranged in order, wherein ceramic sheet 2 and electrode sheet 3 have several groups and mutually spaced arrangement, and by prestress The screws 5 are connected in series through their centers. The material of the back cover 1 can be selected from aluminum alloy, titanium alloy, stainless steel or alloy steel, and the electrode piece 3 is generally made of copper alloy or nickel alloy. A threaded mounting hole is reserved on the front cover 4, and a conventional ultrasonic horn (or directly connected to the mold) can be connected to the front cover 4 by bolts. The ultrasonic transducer of the present invention is sequentially conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com