Rotating lifting appliance for crane

A technology for rotating spreaders and cranes, which is applied in the direction of cranes, load blocks, load hanging components, etc. It can solve the problems that the hook cannot provide a sufficiently stable binding method, the operation tool is dangerous, and the waste of manpower is sufficient to achieve full reliability. Effects of reducing labor burden and increasing safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings:

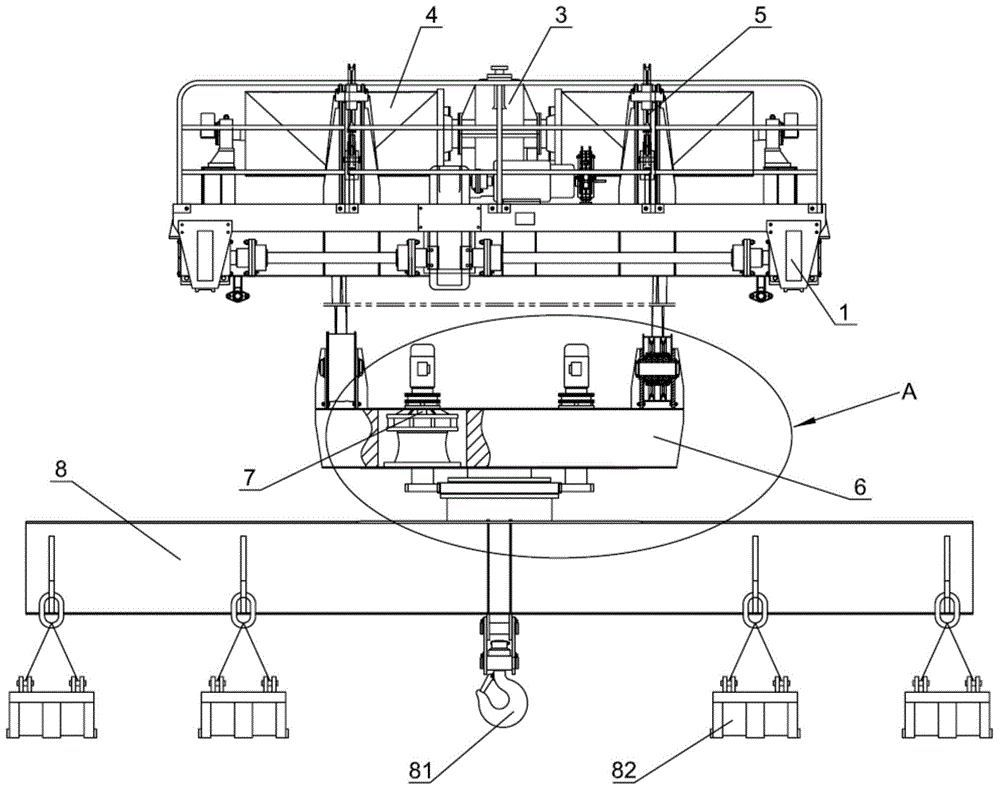

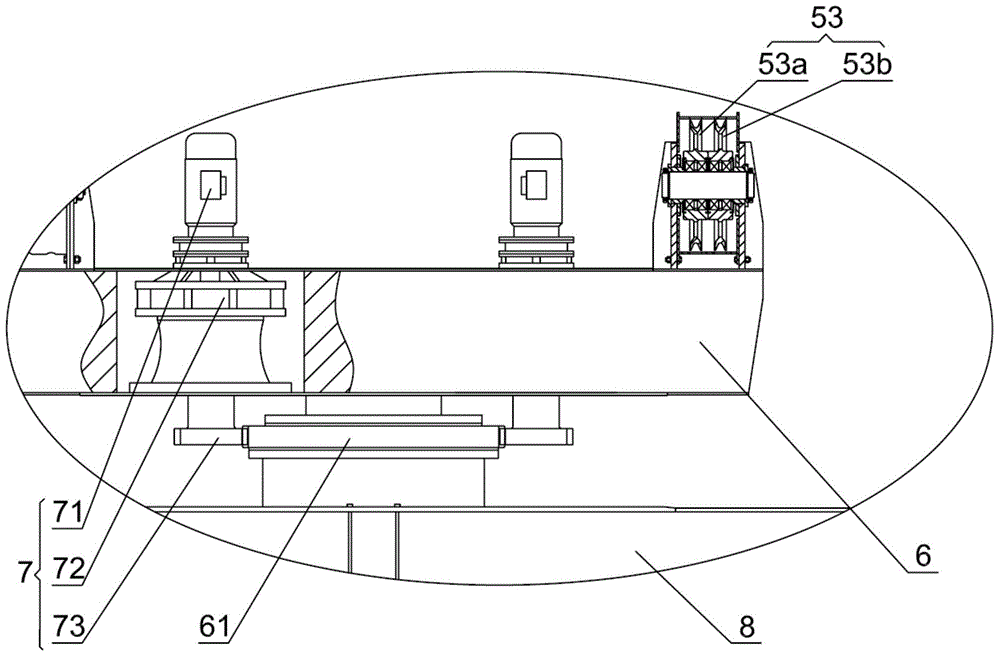

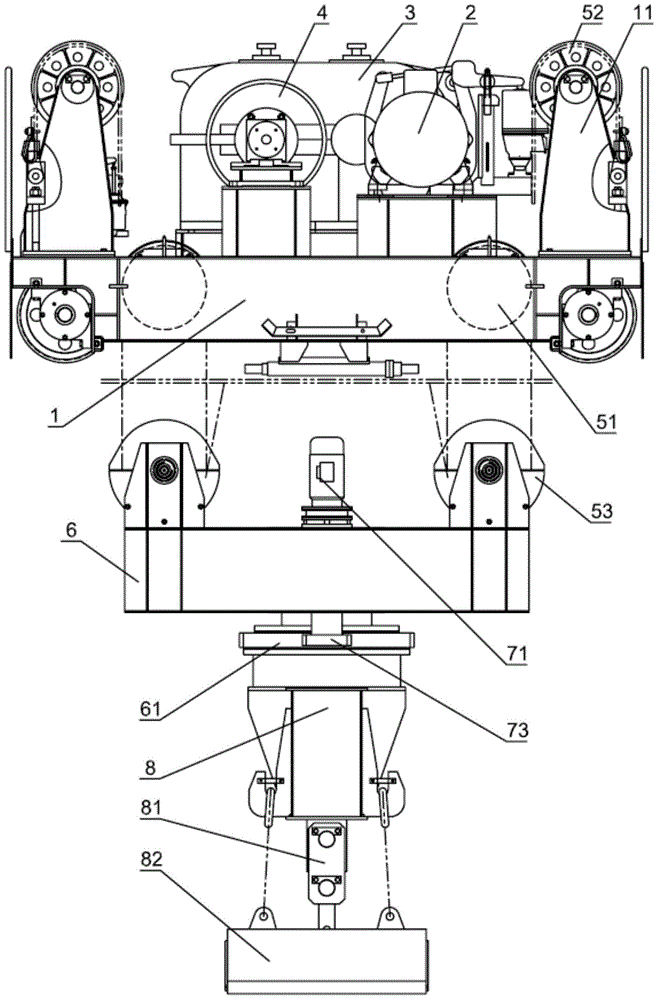

[0015] The invention provides a crane rotating sling, such as attached figure 1 And Figure 4 As shown, it includes a trolley body 1, a lifting drive motor 2, a reduction box 3, two sets of double drums 4, four groups of lifting components 5, a lifting beam 6 and a rotating lifting beam 8. The reduction box 3 is driven by the lifting motor 2 Drive, the double drum 4 is symmetrically arranged on both sides of the reduction box 3 and is fixedly connected with the drive shaft of the reduction box 3. Each double drum 4 contains two steel wires 41, and each double drum 4 passes through the Two steel ropes 41 are connected with two sets of lifting assemblies 5. As attached figure 2 And image 3 As shown, each group of lifting components 5 includes a first fixed pulley 51, a second fixed pulley 52, and a movable pulley 53, the edge of the trolley body 1 is fixedly connected to a support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com