A kind of preparation method of spherical tc4 particle reinforced az91 magnesium matrix composite material

A technology of particle reinforcement and composite materials, applied in the field of composite materials, can solve problems such as poor wettability and poor material performance, and achieve good wettability, good interface bonding, and reduced gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

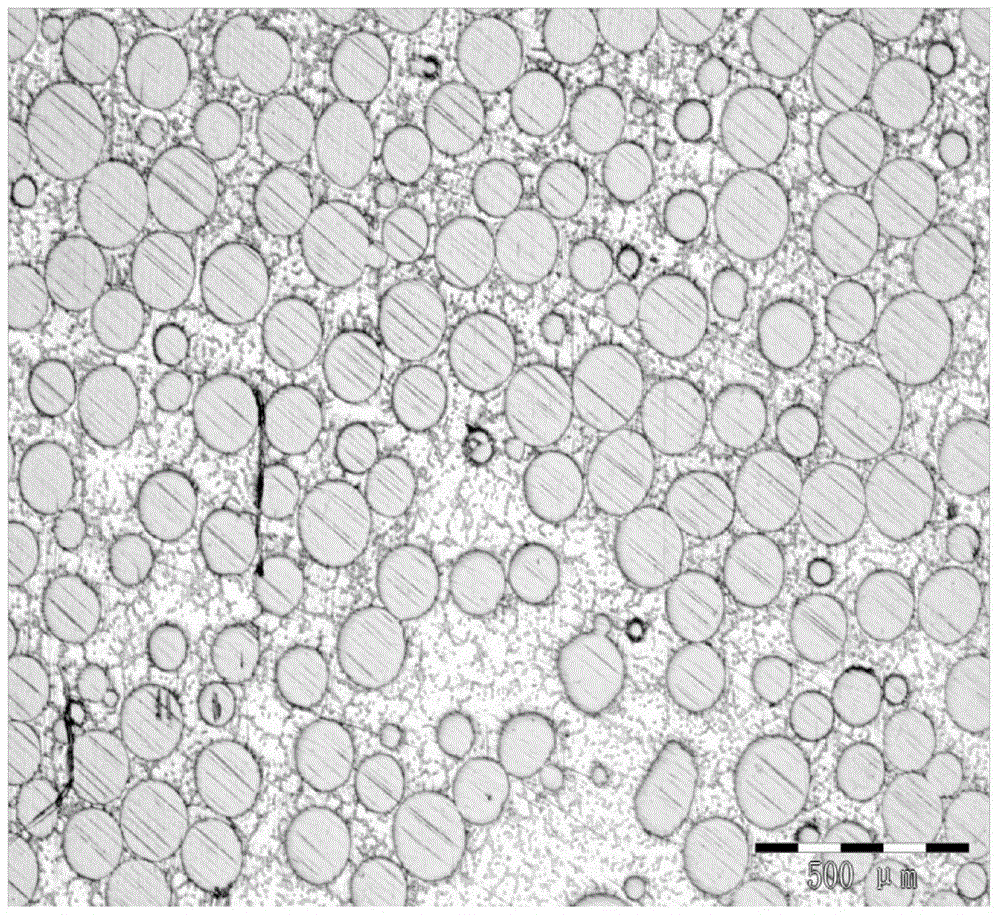

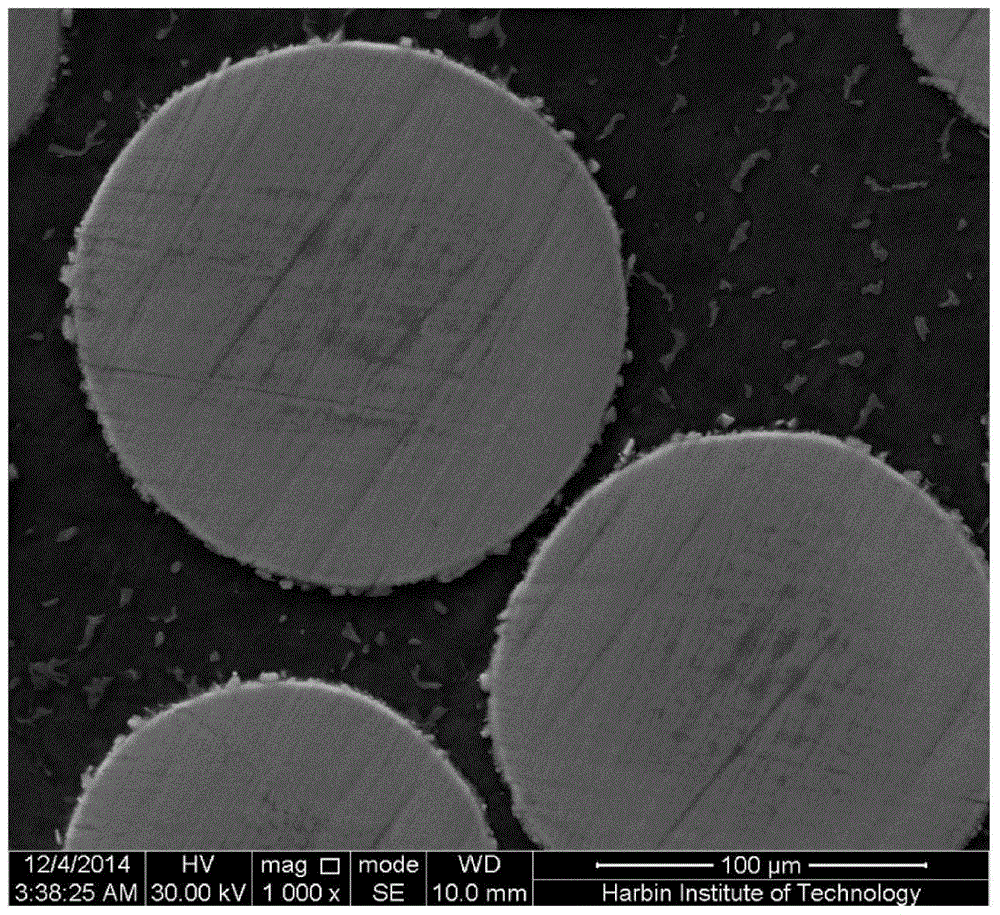

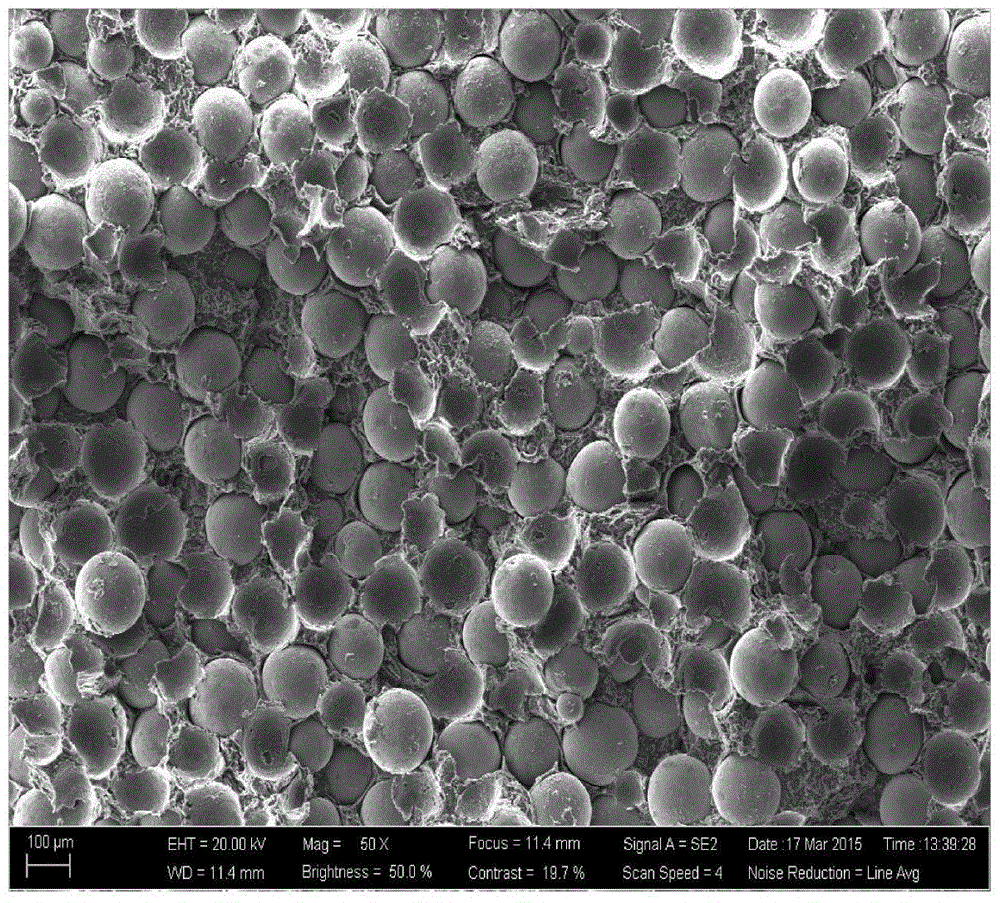

[0021] Specific embodiment one: the preparation method of a kind of spherical TC4 particle reinforced AZ91 magnesium-based composite material of the present embodiment, it comprises the following steps:

[0022] 1. Preheating of TC4 particles: Preheat TC4 particles at 50-100°C for 30-60 minutes;

[0023] 2. Semi-solid stirring: first heat AZ91 to 560-620°C to melt AZ91 to a semi-solid state, then add the TC4 particles preheated in step 1 into the AZ91 semi-solid melt at a speed of 120g / min, adding While stirring, continue to stir for 20-30 minutes after adding to obtain a mixture;

[0024] 3. Ultrasonic treatment: Ultrasonic treatment is performed on the mixture obtained in step 2, the ultrasonic frequency is 20kHz, and the ultrasonic time is 20-30min;

[0025] 4. Self-sedimentation: Let the mixture after the ultrasonic treatment in step 3 stand naturally for 20-30 minutes to make the spherical TC4 particles settle;

[0026] 5. Cooling: cooling the melt treated in step 4 to ...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particle preheating temperature in step 1 is 60°C-100°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the particle preheating temperature in step 1 is 70°C to 100°C. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com