Bionic honeycomb cotton and production method thereof

A manufacturing method, bionic bee technology, applied in the direction of non-woven fabrics, textiles, papermaking, adhesives, etc., can solve the problems of high elasticity, low cost, simple structure, and environmental protection at the same time, so as to improve elasticity, increase cohesion, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

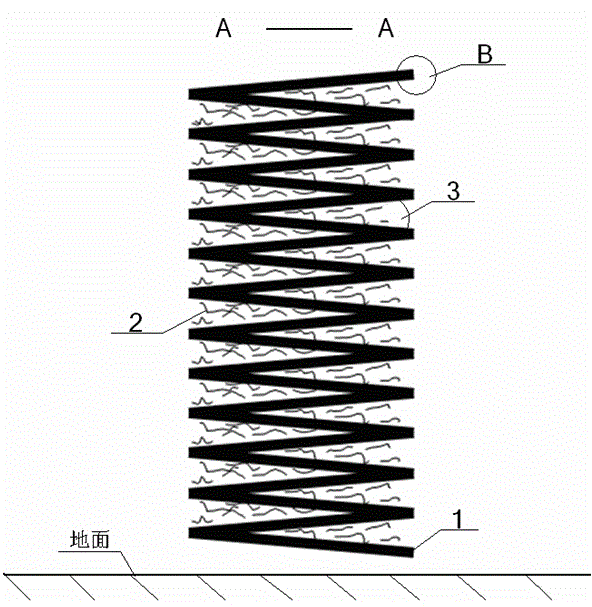

[0064] see figure 1 and figure 2 , a kind of bionic honeycomb cotton, comprising a plurality of bionic honeycomb cotton sub-layers 1 successively laminated along the vertical direction; the bionic honeycomb cotton sub-layers 1 are connected end to end in turn, and sub-layers are sandwiched between adjacent bionic honeycomb cotton sub-layers 1 The included angle 3, the range of the included angle 3 of the sublayer is 0°-2°, and equidistant and side-by-side filaments 2 are arranged on the front and back surfaces of the bionic honeycomb cotton sublayer 1 along its width direction, the filaments 2 has a thickness of 20 D - 300 D, and the distance between adjacent filaments 2 is 5 mm - 300 mm. The filament 2 is a monofilament or a thread, and the thread is composed of two or more Composed of monofilaments, the filament 2 is made of nylon or polyester; the bionic honeycomb cotton sub-layer 1 in the bionic honeycomb cotton is vertically arranged in a Z-shape.

[0065] A method for...

Embodiment 2

[0070] see figure 1 , figure 2 and image 3 , the basic content is the same as in Example 1, the difference is that:

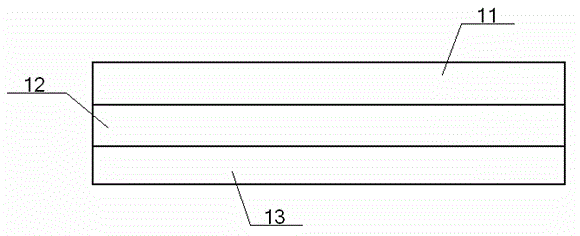

[0071]The bionic honeycomb cotton sub-layer 1 is a composite fiber web of a layered structure, and the composite fiber web includes an upper layer fiber web 11, an elastic fiber web 12, and a lower layer fiber web 13 successively stacked from top to bottom; The composition and weight ratio of the net 11 and the lower fiber web 13 are: hot-melt fiber 15-30, three-dimensional crimped hollow polyester staple fiber 70-85; the composition and weight ratio of the elastic web 12 are: heat Melt fiber 10-25, elastic polyester staple fiber 75-90; the melting point of the hot-melt fiber is ≤110°, and the elastic polyester staple fiber is PTT fiber or elastic polyester ELK fiber.

[0072] The web forming process refers to: during production, the fiber raw materials corresponding to the upper layer fiber web 11, the elastic fiber web 12, and the lower layer fiber web 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation distance | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com