Hand guided roof crack repairing machine

A crack repair and hand-held technology, which is applied to building maintenance, roofing tools, roofing, etc., can solve problems such as uneven pouring and narrow openings, and achieve the effect that it is not easy to slip off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

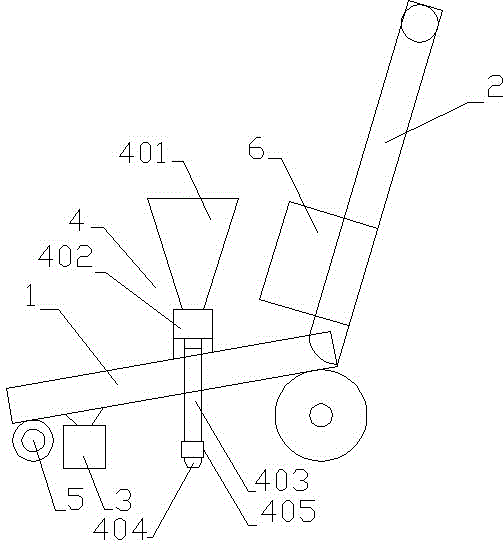

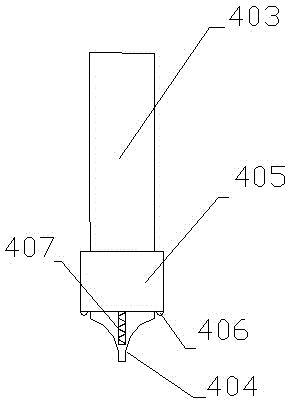

[0030] Embodiment 1: A hand-held roof crack repair machine, the frame is composed of a chassis 1 and an armrest frame 2 arranged at the rear end of the chassis 1 and tilted backward, an angle adjustment mechanism is arranged between the armrest frame 2 and the chassis 1, The inclination angle of the armrest frame 2 can be adjusted. The upper part of the armrest frame 2 is provided with a collection box for storing cables and placing other tools. The lower part of the armrest frame 2 is provided with a motor as the power unit 6. The height of the front end of the chassis 1 from the ground is smaller than that of the rear end of the chassis 1. The height from the ground, the bottom of the chassis 1 is provided with a walking wheel 5, wherein the front end is a universal wheel, the rear end is a driving wheel, and the driving wheel is driven by the above-mentioned power device 6, between the universal wheel and the driving wheel from front to back A slotted plate 3 for widening th...

Embodiment 2

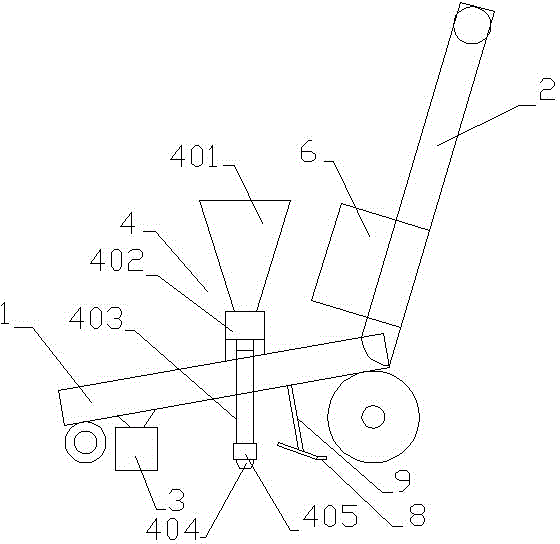

[0033] Embodiment 2: A hand-held roof crack repairing machine. On the basis of the structure of Embodiment 1, a leveling device is arranged behind the pouring pipe 403, and the leveling device includes a height that is fixedly connected to the chassis 1. The adjusting rod 9 and the scraper 8 arranged at the bottom of the height adjusting rod 9, the scraper 8 is composed of an inclined part and a horizontal part, the front end of the inclined part is high, the rear end is low, the horizontal part is connected with the rear end of the inclined part, and then the The poured repair material is scraped off at the opening of the crack, and the height of the scraper 8 from the ground is adjusted by the height adjustment rod 9 .

Embodiment 3

[0034] Embodiment 3: a kind of hand-held roof crack repairing machine, on the structural basis of embodiment 1, a blade is set on the edge of the groove of the grooved plate 3, and a frosted layer is set on both sides of the grooved plate 3, During the repair process, sand the crack edges.

[0035] The repair material mentioned above is made by mixing cement and gelatinous materials. For example, the cement mortar slit treatment disclosed in a hydraulic concrete surface slit sealing treatment method (authorized announcement number is CN 101994306 B) can be used. The material is used to repair roof cracks. After repairing, it has good adhesion and sealing properties, as well as waterproof and crack resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com